Dancer position control (linear drive)

15

Application examples

15.4

L

15.4-1

EDS82EV903-1.0-11/2002

15.4 Dancer position control (linear drive)

The dancer position controls the material tension while the machine is running.

The example describes the synchronisation of material web speed v

2

to line

speed v

1

. This application requires an application-I/O.

l Internal process controller as position controller.

l Selection of the line speed v

1

via X3/1U.

l Actual dancer position value of dancer potentiometer via X3/2U.

l Setting-up speed via X3/E3 as JOG value.

l Dancer position controller switch off via X3/E4 (external) or internally via

Q

min

(C0017) and C0415/1 = 6.

l Basic settings.

l Motor parameter identification. (¶ 10.9-1)

l

If necessary, calibration of setpoints and actual values to process variables.

(¶ 10.16-1)

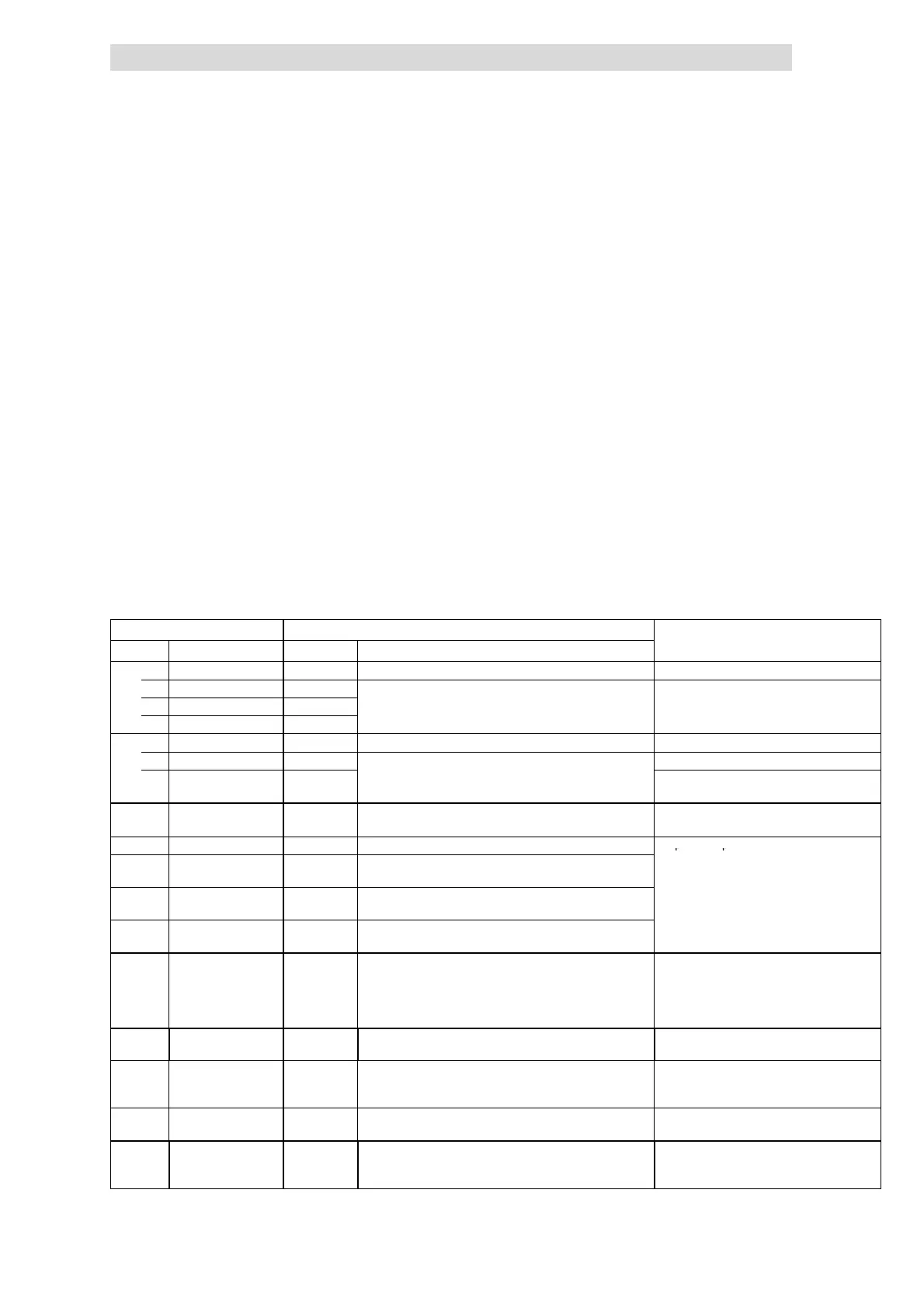

Code Settings IMPORTANT

No. Name Value Meaning

C0410 Digital signals source

1 JOG1/3 3 X3/E3 Setpoint setting

4 QSP 2 X3/E2 Quick stop activation

19 PCTRL1-OFF 4 X3/E4 Dancer position controller switch off

C0412 Analog signal source

1 Setpoint 1 (NSET1-N1) 1 X3/1U Line speed v

1

5 Act. process controller

value (PCTRL1-ACT)

4 X3/2U Actual dancer position value

C0037 JOG1 20.00 Fixed set-up speed v

1

for material guidance,

individually adjust able.

C0070 Process controller gain 1.00

Adaptation to process

C0071 Process controller

readjust me nt time

100

More information: ^ 10.10-1

C0072 Differential component

of process controller

0.0

C0074 Process controller

influence

10.0 %

C0105 Deceleration time QSP approx. 1 s E.g. as emergency stop function. The settings

must ensure braking of the controller to

standstill within a very short time. Check

whether the application needs an external

brake resistor.

C0145 Process controller

setpoint source

1 C0181 (PCTRL1-SET2)

C0181 Process controller

setpoint 2

(PCTRL1-SET2)

Value of

C0051

Position the dancer a s re quired, C0051 = read actual dancer

position value.

C0181 should not be set to “0”, because t he

position setpoint would be generated from the

mains setpoint.

C0239 Lowest frequency limit 0.00 Hz Direction of rotation cannot be changed via the

process controller.

C0238 Frequency precontrol 1 Precontrol (total setpoint + process controller)

Total setpoint (PCTRL1-SET3) = Main setpoint + additional

setpoint

Process controller has limited influence.

Functions used

Application-specific

configuration