Setpoint summation (basic and additional load operation)

15

Application examples

15.8

L

15.8-1

EDS82EV903-1.0-11/2002

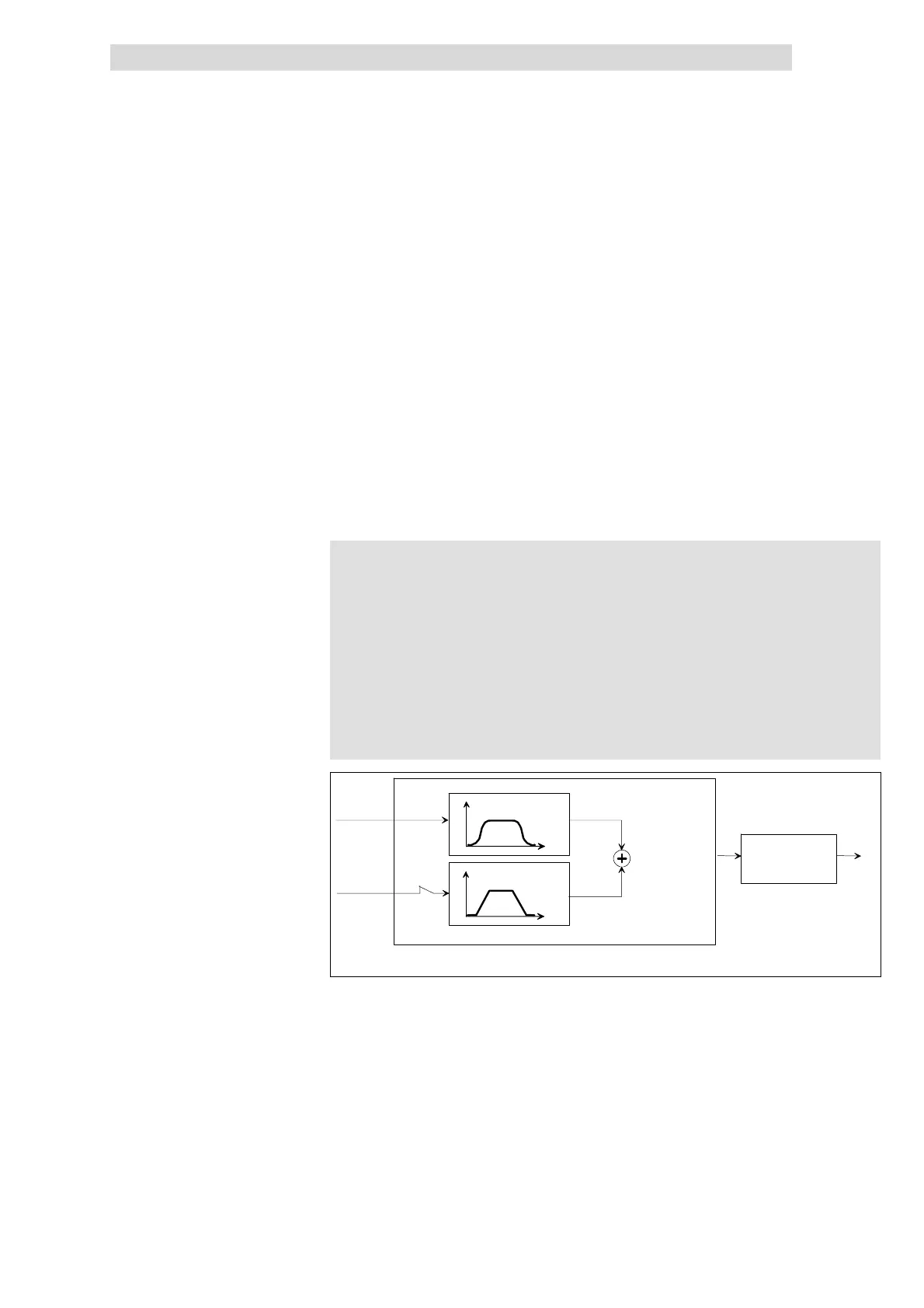

15.8 Setpoint summation (basic and additional load operation)

Conveyors, pumps, etc. are often operated at a speed which is increased if

necessary.

The speed is set by selection of a main and additional setpoint. The setpoints can

have different sources (e.g. PLC or setpoint potentiometer). The controller adds

both analog setpoints and increases the motor speed accordingly.

For smooth acceleration, acceleration and deceleration ramps of both setpoints

can be adjusted. The main setpoint ramps can have a S-shape.

l Basic settings.

l Setpoint summation configuration: Assign the setpoints to be added to

C0412/1 and C0412/3.

(¶ 10.12-1)

l

If necessary, adjust the main setpoint ramps under C0182. (¶ 10.7-1)

)

))

) Note!

l Possible ways to select a setpoint: (¶ 10.8-1 ff)

l The additional setpoint can be displayed under C0049

(alternatively: C0412/3 = 0).

l With controllers with standard I/O, the main setpoint must be

selected via PC, keypad, JOG frequency or the function ”Motor

potentiometer” because there is only one analog input

available.

l If you use an application I/O, the additional setpoint can be

switched on and off during operation ( (C0410/31 ≠ 0)

0

1

2

34

K35.82M001

Fig. 15.8-1 Principle of setpoint summation

0

Main setpoint

1

Additional setpoint

2

S-ramps

3

motor

4

speed

Application-specific

configuration