Manitowoc Published 12-05-17, Control # 032-23 3-71

18000 OPERATOR MANUAL OPERATING CONTROLS AND PROCEDURES

HYDRAULIC SYSTEM CALIBRATION

PROCEDURES

General

To ensure proper operation of the crane functions, the

following items must be calibrated or tested at the intervals

specified in this folio:

• Pressure Senders

• Controls (pump centers)

• Pump Pressure

• Charge Pressure

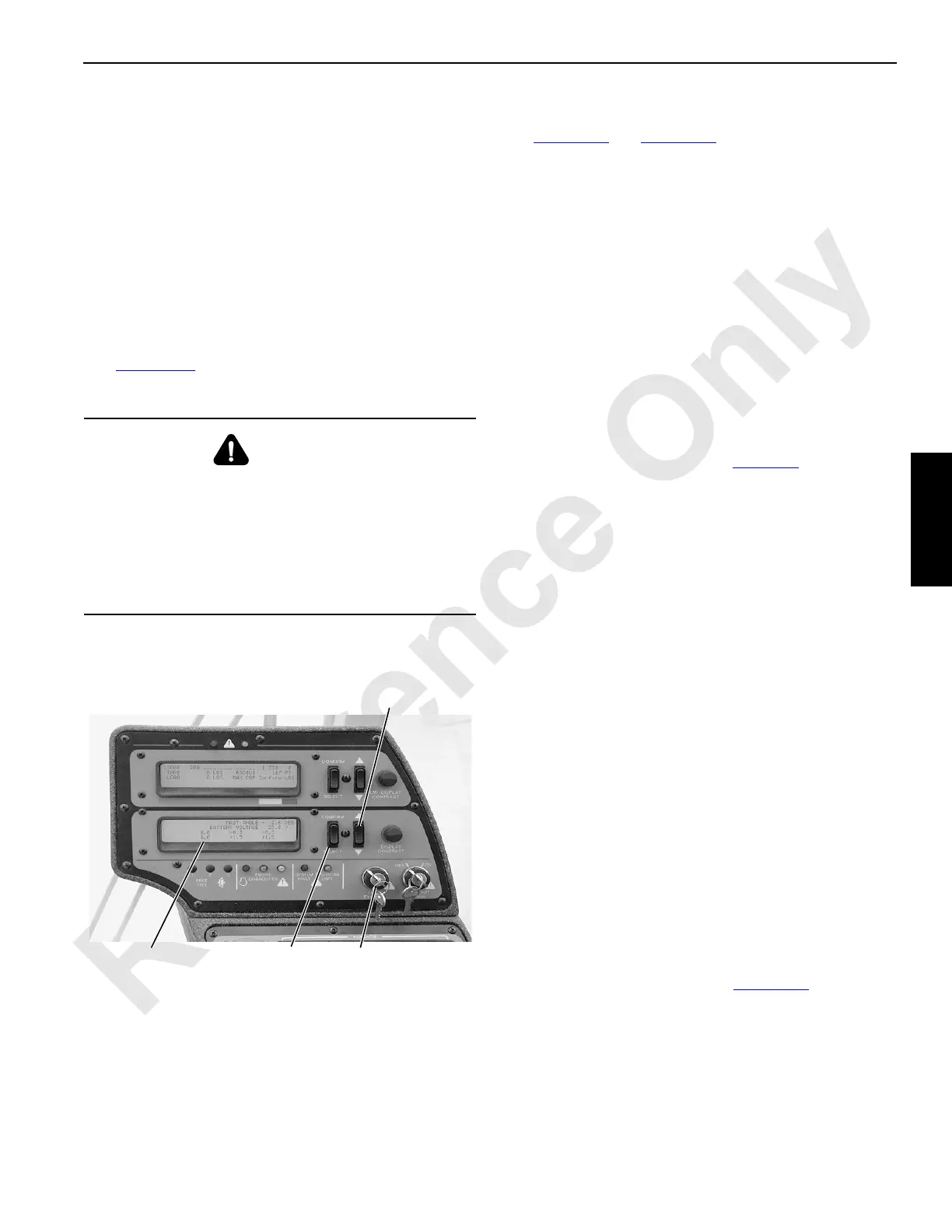

See Figure 3-47

for identification of the controls used for

calibration and testing.

Pressure Sender Calibration

See Figure 3-47 and Figure 3-48 for the following procedure.

The pressure sender line of the calibration screen indicates if

each system’s pressure sender null (0) is within 0.65-1.35

volts.

The pressure senders must be calibrated at the following

intervals:

• When a new controller node is installed

• When a pump is replaced

• When a pump control (EDC or PCP) is replaced

• When a pressure sender is replaced

• When displayed pressure is not correct

Be aware that if there is any residual pressure in the

system during the calibration process, the display

pressure reading in the cab may not reflect actual

system pressure. See Note on page 3-71

.

• Every 6 months

To perform pressure sender calibration, proceed as follows:

1. Stop engine and turn ignition switch to RUN position.

2. Access calibration screen shown below as follows:

a. Select and confirm SETUP mode to activate

calibration program.

b. Turn LIMIT BYPASS switch clockwise and hold.

c. SCROLL UP at least one screen.

d. Continue to scroll up or down until calibration screen

appears.

e. Press bottom of CRANE MODE switch until (*)

appears next to PRESSURE SENDER CAL.

f. Then press top end of CRANE MODE switch to

CONFIRM. Calibration will start.

g. When calibration starts, percent (%) of completion is

displayed on screen.

h. When calibration stops, check bank 1 and bank 2

binary numbers:

- If 0 appears, all pressure senders have passed

calibration.

- If any number other than 0 appears in either

bank, use the table in Figure 3-48

to determine

which senders have failed calibration.

- Each pressure sender is assigned a number in

the binary system (power of two). After running

the calibration procedure, outputs that are ON

(failed) for any sender, are added together. To

identify the failed senders, find the binary

WARNING

Moving Load Hazard!

With engine running, crane functions (drums, boom hoist,

swing, travel) can operate unexpectedly while system

components are being calibrated or tested.

To prevent crane functions from moving, turn PARK ON

for all crane functions before you perform calibration or

testing procedures.

P1744

Digital

Display

Screen

Scroll

Up-Down

Rocker

FIGURE 3-47

Crane

Mode

Switch

Limit Bypass

Switch

Loading...

Loading...