SET-UP AND INSTALLATION 18000 OPERATOR MANUAL

4-136

Published 12-05-17, Control # 032-23

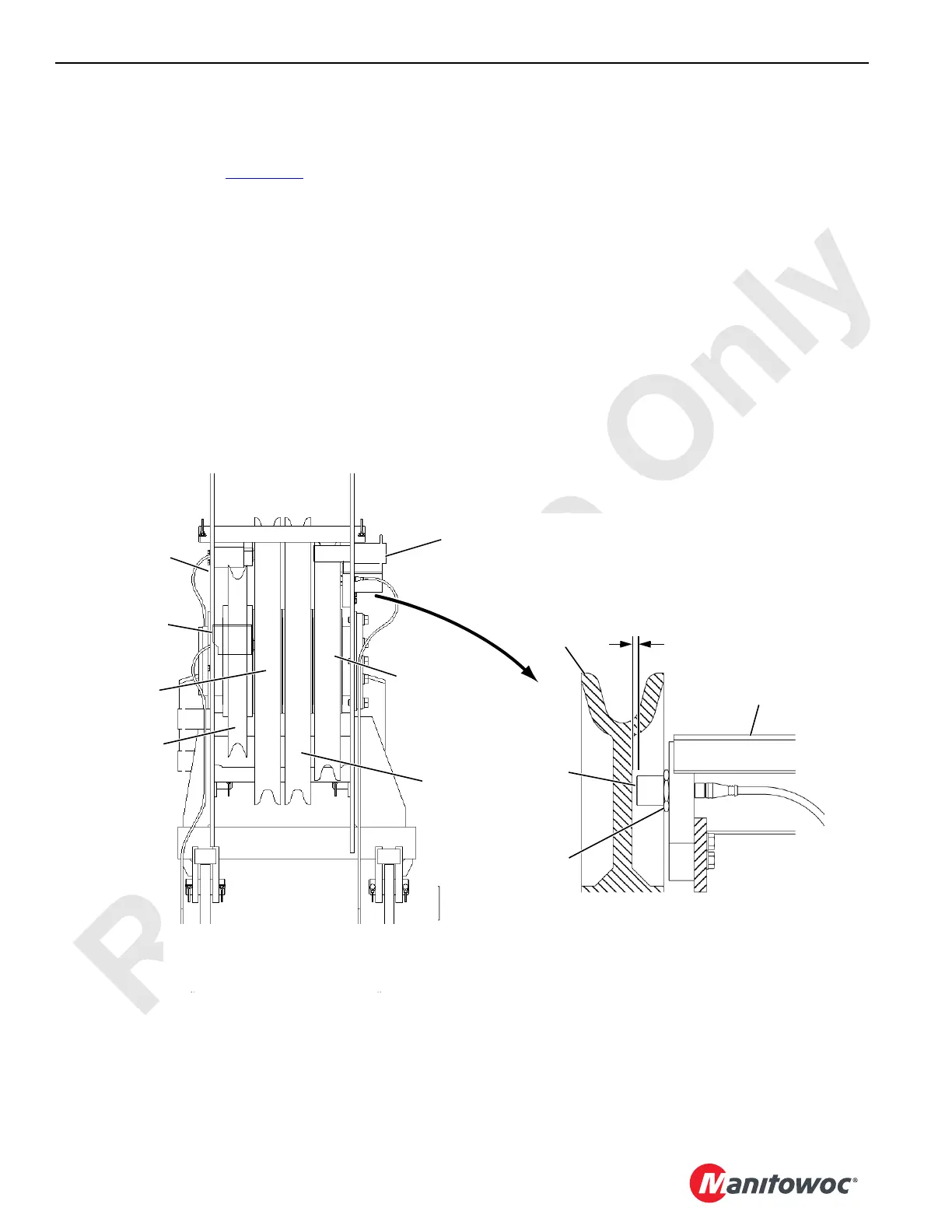

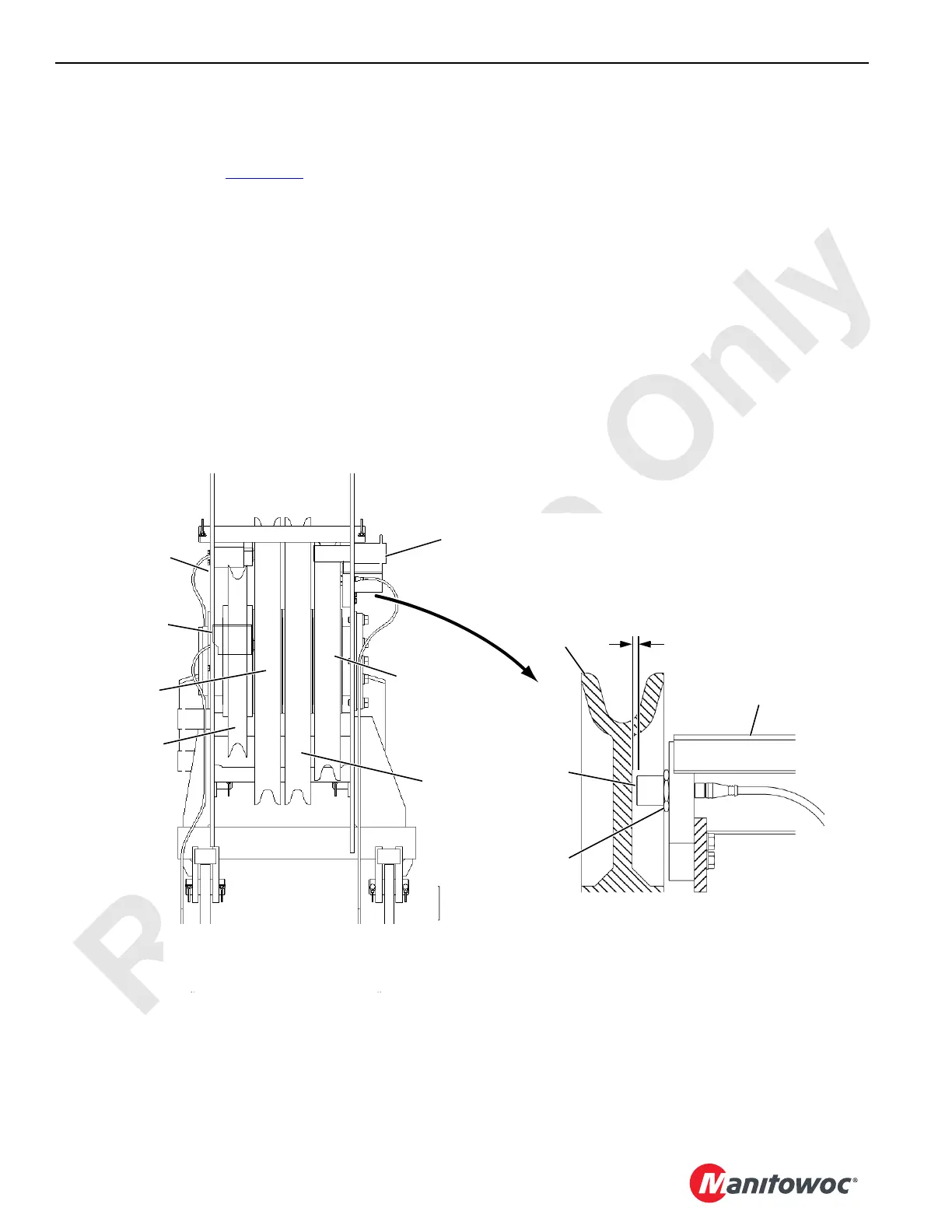

BLOCK LEVEL SENSOR ADJUSTMENT

General

The block level sensors (Figure 4-80) ensure that the load

block remains level when two load lines — Drums 1 and 2 —

are routed to the load block.

NOTE This block level is only on cranes without wireless

communication. On cranes with wireless

communication the controller adjusts the block

level automatically (see Crane Diagnostics, Block

Level Sensor topic in Section 3 of this manual).

The sensors monitor guide sheave rotation speed. The

crane’s programmable controller uses signals from the

sensors to equalize the rotation speed of the drums so the

load block remains level.

The sensors were adjusted at the factory and need to be

readjusted only when a new sensor is installed or the

position of a sensor is changed.

Sensor Adjustment

1. If necessary, attach mounting bracket to guide sheave

frame with cap screws.

2. Loosen jam nut securing sensor to bracket.

3. Turn sensor in or out to obtain specified dimension

between end of sensor and wall of sheave.

4. Tighten jam nut.

5. Check for proper operation without load. Drums should

operate at same speed and load block should remain

level.

Readjust sensor if required.

Sheave

for Drum 1

Sensor #2

#79A

Boom

Sheave

Sensor

Jam

Nut

0.39 in (9,906 mm)

MAXIMUM

Mounting

Bracket

Sheave for

Drum 6

Sensor

#1

Front View

of Boom Top Guide Sheaves

Sensor #2

#55 & 55A

Boom

Sheave for

Drum 3

Sheave for

Drum 2

FIGURE 4-80

4-230

Loading...

Loading...