GROVE 5-29

CD3340B/YB4411 MAINTENANCE

Published 04/07/2015 Control # 569-00

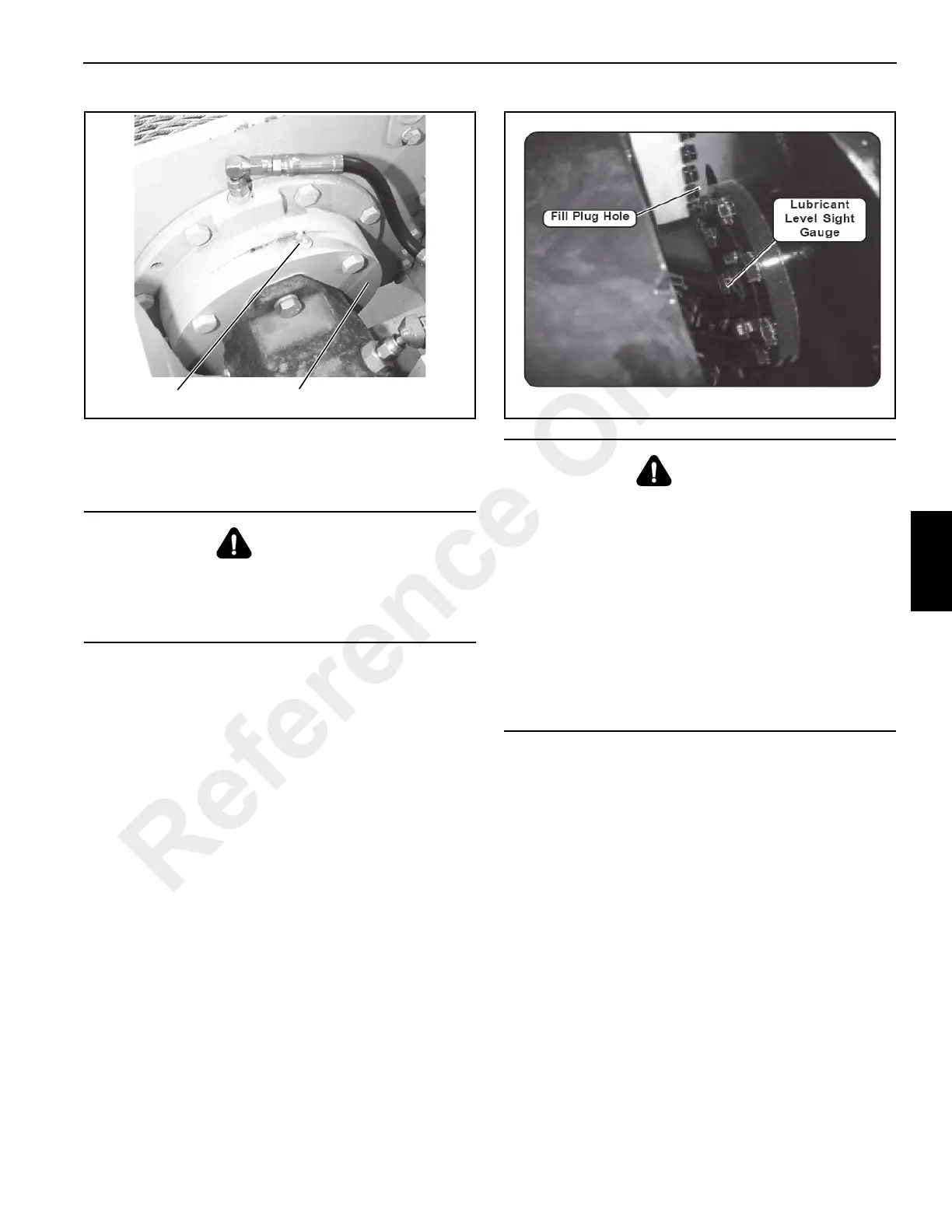

7. Remove the check plug (Figure 5-58).

8. Check the lubricant level, which should be level with the

bottom of the check plug hole.

9. If necessary, add Mobil 424 hydraulic oil, or equivalent,

through the breather hole to fill the brake level with the

bottom of the check plug hole.

10. Install both the breather and the check plugs.

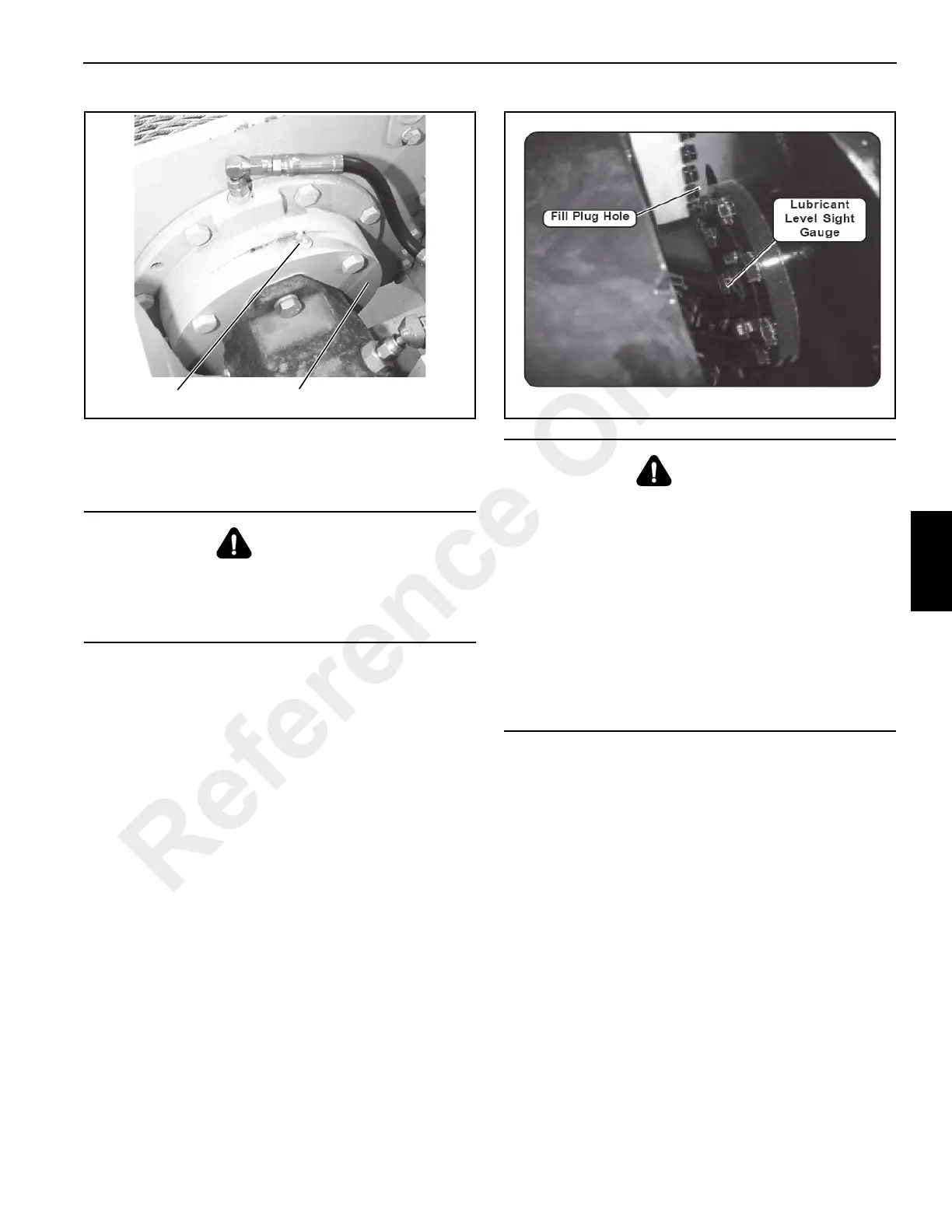

Check Hoist Gearbox and Brake Lubricant (Braden

Model)

1. Lower the boom to its lowest position.

2. Engage the parking brake and shut off the engine.

3. Clean the lubricant level sight gauge (Figure 5-60).

4. Using a mirror, and light if needed, check the lubricant

level in the sight gauge. Lubricant must be visible in the

sight gauge.

5. If lubricant must be added, rotate the hoist drum until the

drain/fill plug is visible in the access hole aligned with the

level sight gauge.Clean around the drain/fill and then

remove it. Add recommended lubricant (see Section 8)

through the plug hole until it exits the fill plug hole. Install

the plug.

1000 Hours of Operation/Six Months

NOTE: You must read and understand the warnings and

basic safety rules, found in Safety Practices page

2-1 of this manual, before performing any operation

or maintenance procedures.

For additional engine maintenance guidelines, see

the engine manual furnished with this crane.

Replace the Transmission Oil and Filter

1. Engage the parking brake and shut off the engine.

Remove the ignition key.

NOTE: It is necessary to climb under the crane to drain the

transmission oil. Be sure engine is shut off, the

ignition key is removed and chock blocks are in

place before climbing under the crane.

NOTE: When the strainer is removed, oil will gush out.

Keep to one side when you remove the strainer.

DANGER

Do not use EP type gear lube in the brake section of this

hoist. EP lube may prevent the clutch from locking up,

causing the load to fall and resulting in property damage,

personal injury or death.

p0321

FIGURE 5-59

Check Plug

Location

Breather

DANGER

Failure to use the proper type and viscosity of planetary

gear oil may contribute to intermittent brake clutch

slippage which could result in property damage, severe

personal injury or death. Some gear lubricants contain

large amounts of EP (extreme pressure) and anti-friction

additives which may contribute to brake clutch slippage

and damage to brake friction discs and seals. Oil viscosity

with regard to ambient temperature is also critical to

reliable brake clutch operation. Test have indicated that

excessively heavy or thick gear oil may contribute to

intermittent brake clutch slippage. Make certain that the

gear oil viscosity in the hoist is correct for prevailing

ambient temperature.

Reference Only

Loading...

Loading...