GROVE 8-39

CD3340B/YB4411 AXLES/DRIVE SHAFTS/WHEELS AND TIRES

Published 04/07/2015 Control # 569-00

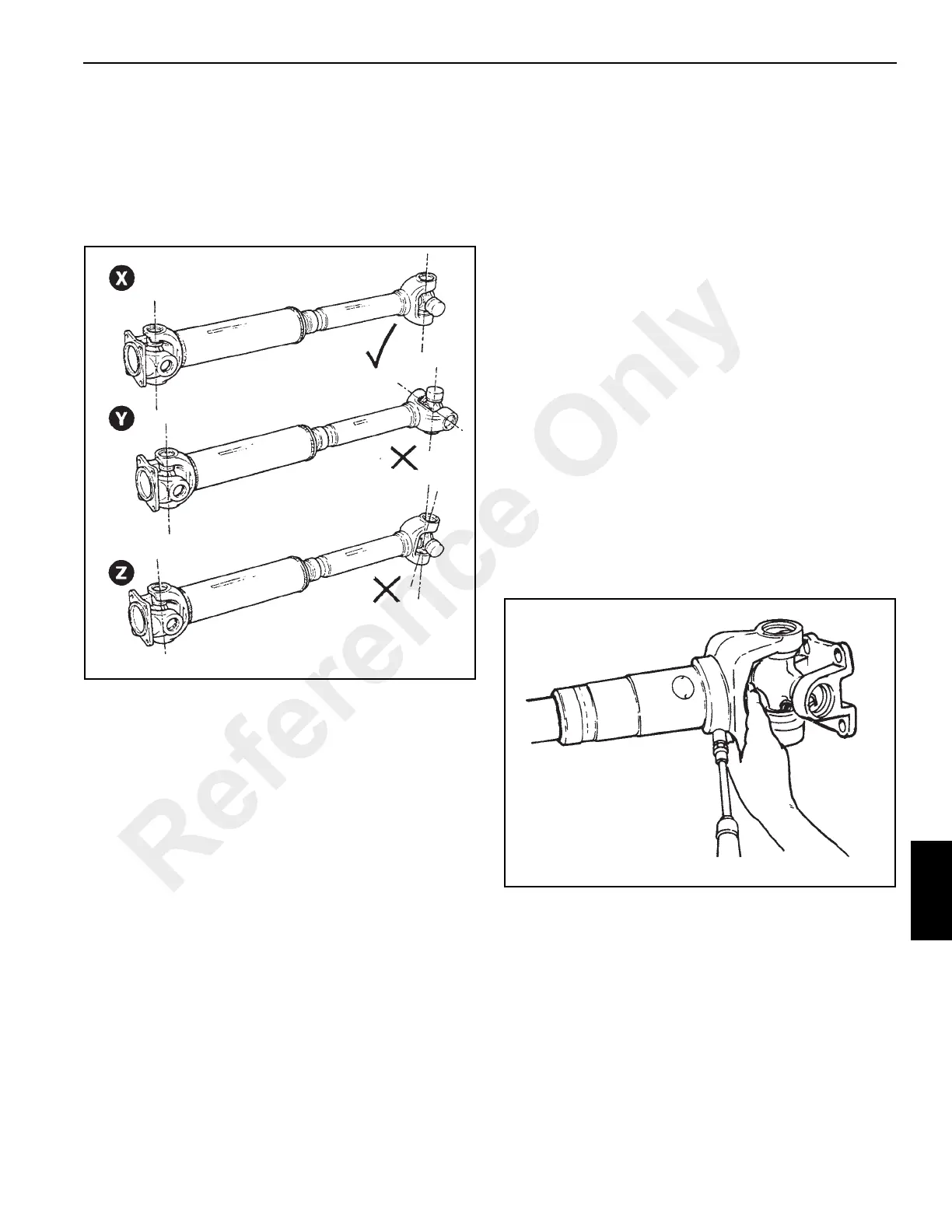

5. Repeat steps 1 through 3 and install a flange yoke (1) to

each end of the drive shaft.

6. Apply SAE 140 oil to the splines on the slip tube (3).

Assemble the dust cap assembly to the slip tube. Slide

the slip tube into the slip yoke (4). Make sure both ends

of the drive shaft are in the same plane. See “X” in

Figure 8-141. Tighten the dust cap assembly.

Installation

1. Fasten the flange yoke to the parking brake disc on the

front axle with four capscrews and lockwashers.

NOTE: The drive shaft must have both ends exactly on the

same as shown in “X” of Figure 8-141. The yokes

must not be at right angles as at “Y” or at an

intermediate angle as in “Z”.

2. Fasten the other end to the transmission with four

capscrews and self-locking nuts.

3. Apply a Lithium Base, E.P. No. 2 bearing grease to the

three grease fittings on the drive shaft. One fitting on

each journal cross and one on the slip yoke. Apply the

grease until it exits through the seals. See Lubrication

Procedure on page 8-39.

4. Check the drive shaft for correct balance before the

machine is put into operation. Lower the outriggers to lift

the wheels off the ground. Operate the drive train and

check for vibration. If vibration is found, stop the engine

and check the drive shaft. Make sure the drive shaft

yokes are in the same plane. If they are the drive shaft

needs to be balanced. Do not drive the crane with an

unbalance drive shaft, possible damage to drive train

could occur.

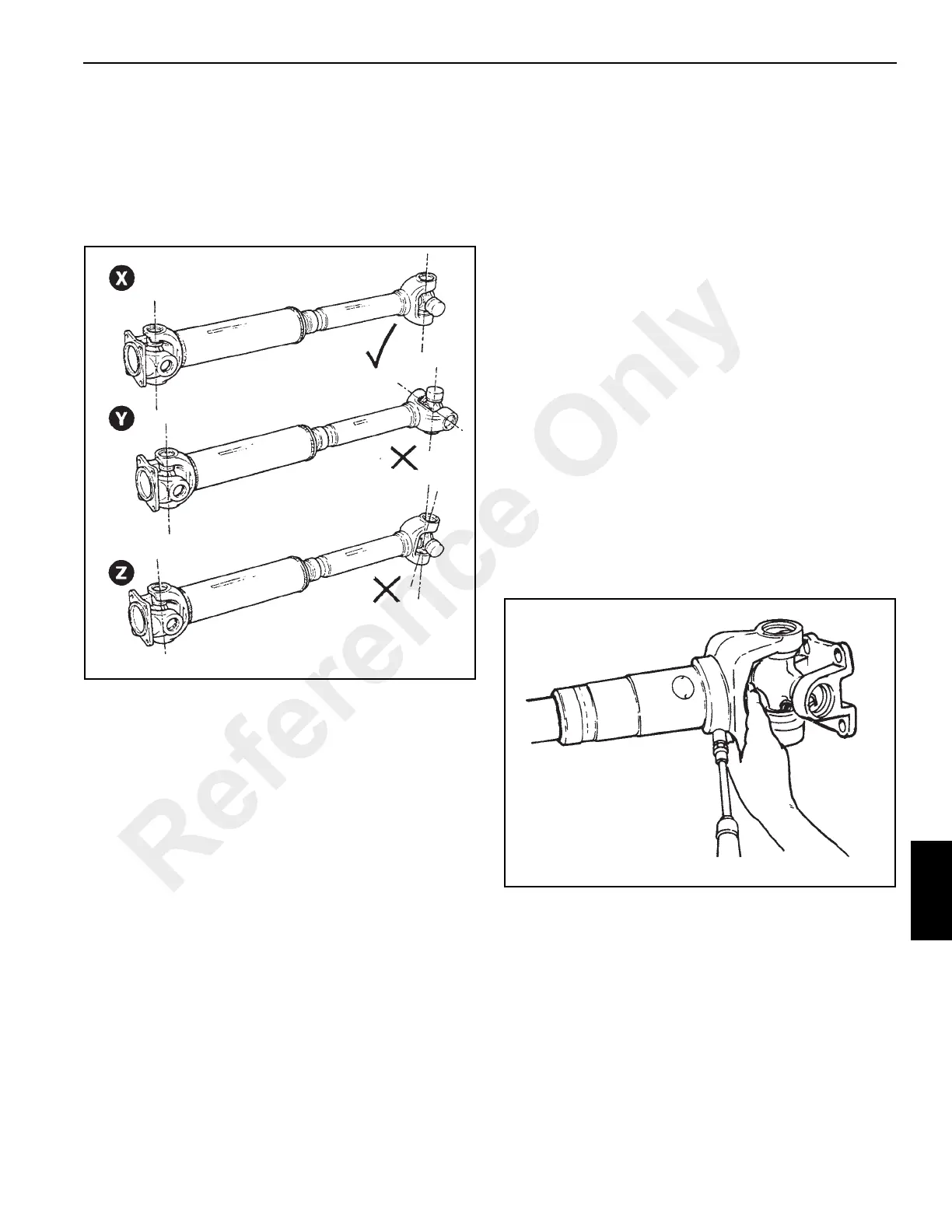

Lubrication Procedure

The drive shaft is an important part of the drive train and

needs regular maintenance. There is a grease fitting on the

slip joint and on each journal bearing cross. Apply grease to

these fittings after every 50 hours of operation. Use a Lithium

Base, E.P. No. 2 bearing grease. Always apply enough

grease to remove the old grease. On the slip joint, apply

grease to the grease fitting until grease comes through the

hole in the end of the shaft. Put your finger over the hole

(Figure 8-142) and continue to apply grease until the grease

shows at the seal on the slip joint.

Reference Only

Loading...

Loading...