HYDRAULIC SYSTEM CD3340B/YB4411

4-44

Published 04/07/2015 Control # 569-00

NOTE: Do not stretch the seal too far. The seal will not

return to its original shape. If the seal diameter is

too large, damage to the seal will occur when the

spool is installed into the housing.

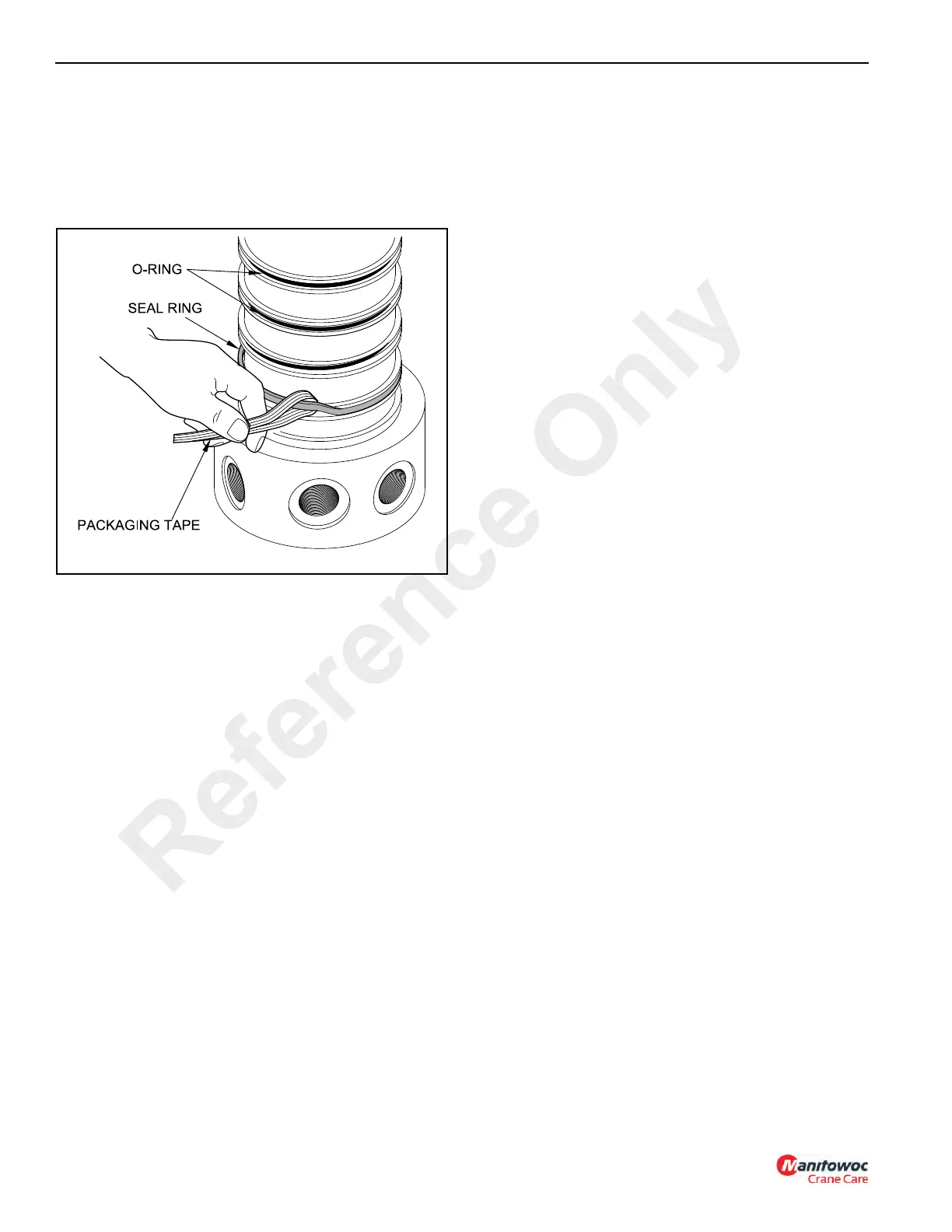

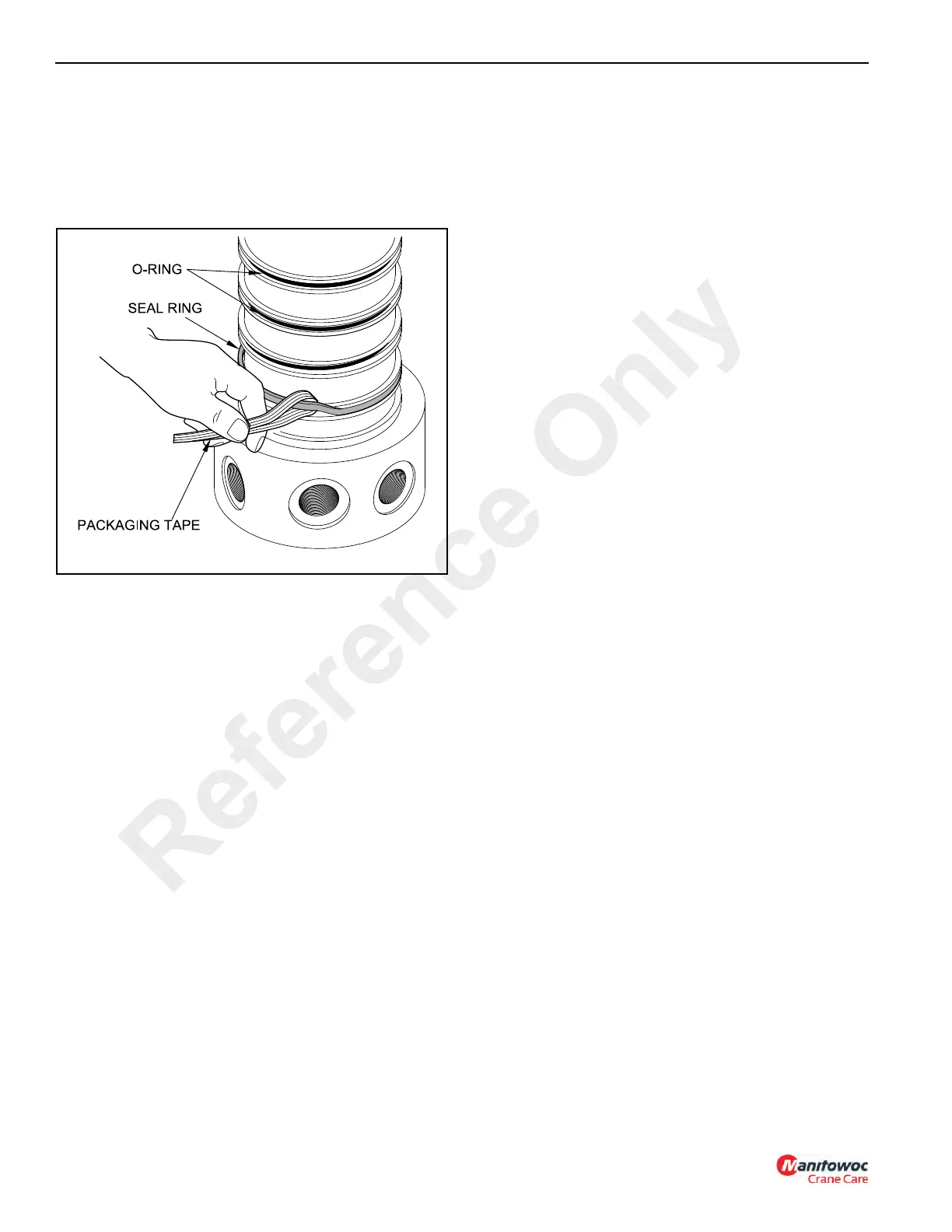

9. Slowly pull the tape from the seal ring, being careful not

to damage the seal.

10. Repeat steps 5 through 8 for the remaining seal

grooves.

11. Install the top seal (6, Figure 4-36) to stem (7).

12. Place the swivel housing (5) on the work bench with

bottom of the housing up. Lubricate the lower 1/4 of the

bore of the swivel housing with hydraulic oil.

13. Insert the assembled stem into the housing and then

push the stem into the housing bore until it is seated.

14. Install thrust washer (4), O-ring (3) and plate (2).

15. Install three hex socket flat head capscrews (1) and

tighten to a torque of 41 Nm (30 lb-ft).

Test

Pressure test the hydraulic swivel at 24,132 kPa (3500 psi).

Test each port individually for approximately 1 minute while

rotating the swivel stem 360°. No leakage past the seals is

permitted.

If internal bypass should occur, rotate the swivel stem and

then back pressure the port that the oil was leaking into. If

bypass persists, disassemble the swivel and examine for

damaged seals. If external leakage occurs, disassemble the

swivel, identify the defective component, and replace.

Installation

1. Put the hydraulic swivel in place on the machine. Fasten

the hydraulic swivel to the brackets in the mast using

three bolts and lockwashers.

2. Install the swivel stop to the bottom of the hydraulic

swivel using three bolts and lockwashers.

3. Connect the hydraulic lines to the lower ports of the

hydraulic swivel.

4. Fill the lower hydraulic system by adding recommended

hydraulic oil through the upper ports of the hydraulic

swivel.

5. Connect the hydraulic lines to the upper ports.

6. Start the engine and move the hydraulic oil through the

swivel by actuating all functions. Visually, check for

leaks.

NOTE: Do not rotate the mast until the oil has moved

through the hydraulic swivel for several minutes.

Hydraulic Cylinders

Removal

NOTE: The following removal instructions are general and

should be modified to suit the cylinder being

removed. Telescope cylinder and outrigger cylinder

removal instructions will be found in SECTION 11.

Steering cylinder removal instructions can be found

in SECTION 10.

1. Put a support under the component to which the cylinder

is fastened. Make sure the component will not fall after

the cylinder is removed.

2. Stop the engine. If the lift cylinder is being removed,

before disconnecting any lines or hoses from the

cylinder, let the system bleed down for approximately 10

minutes. Even then slowly disconnect any hose to allow

any pressure still in the circuit to release.

3. Disconnect the hydraulic lines from the cylinder. Put

caps on the hydraulic lines and plugs on the cylinder

ports to keep dirt out of the system.

4. Connect a hoist to lift the weight off the cylinder.

5. Remove the cylinder mounting pins. Remove the

cylinder.

Disassembly

NOTE: The following procedures gives general

instructions for repair of the hydraulic cylinders.

See illustrations for relation of the component

parts. Steering cylinder repair instructions can be

found in Steering System, page 10-1.

Reference Only

Loading...

Loading...