HYDRAULIC SYSTEM CD3340B/YB4411

4-34

Published 04/07/2015 Control # 569-00

should be smooth and free of nicks, scratches or grooves.

Examine O-rings and backup washers for any damage and

replace if necessary. All moving parts should slide freely, with

oil seal friction being present.

After inspecting and cleaning, immerse all parts in hydraulic

oil and reassemble. Since the pressure setting was not

disturbed, the relief valve can be tested for proper function

under actual working conditions.

If operating difficulties indicate that the pilot poppet is leaking

or sticking, remove internal parts of the pilot section, and

follow the same procedure as above. After assembly, adjust

the relief valve pressure per instructions in this section.

If the relief valve still does not function properly, replace the

relief valve.

Relief Valve Troubleshooting

Table 4-9

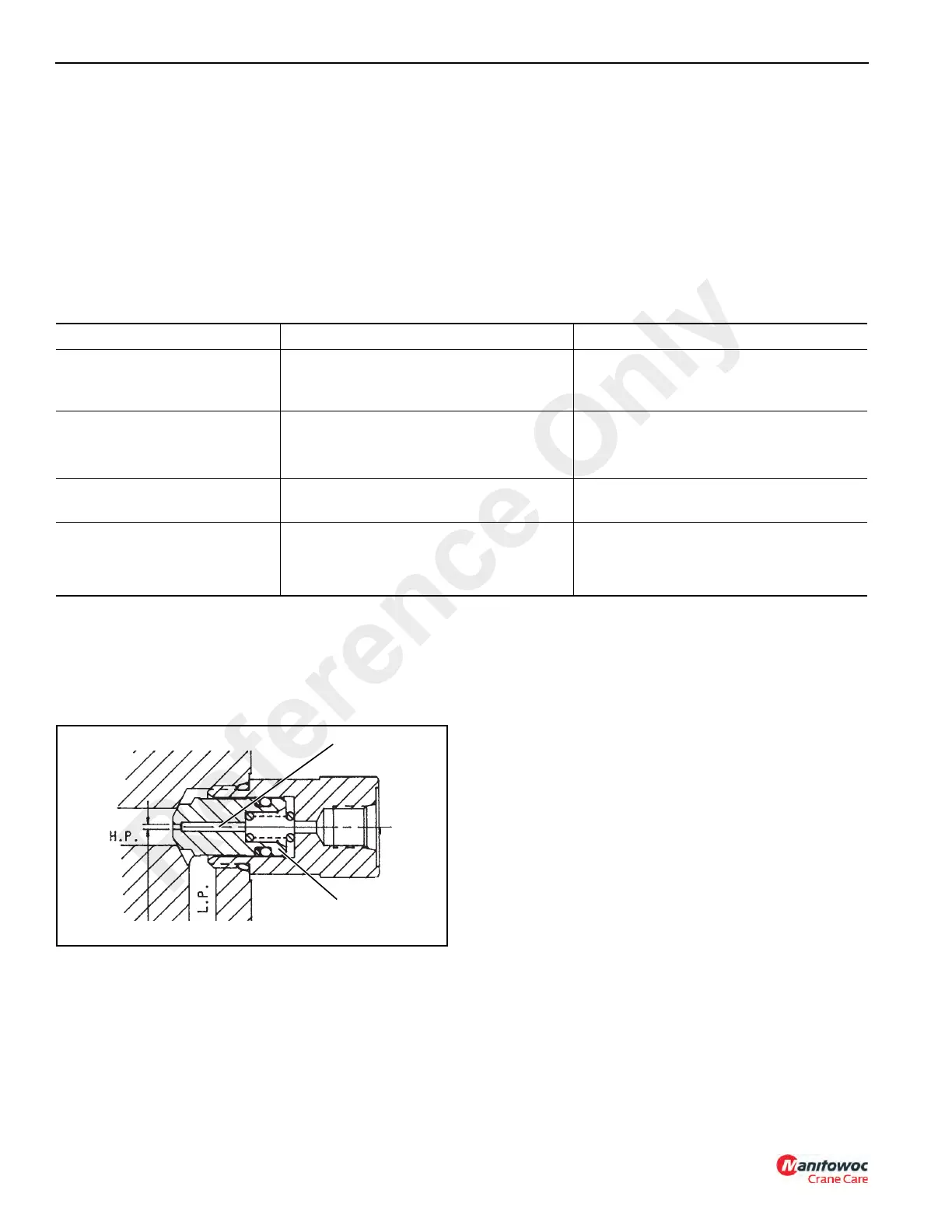

Anti-Void Troubleshooting

Trouble resulting in a malfunctioning anti-void valve can

usually be traced back to foreign matter plugging the sensing

hole or preventing free movement of the poppet. Also, check

seat for scratches, nicks or other marks.

If operating difficulties indicate that the pilot poppet is leaking

or sticking, remove internal parts of the pilot section, and

follow the same procedure as above. After assembly, adjust

the relief valve pressure per instructions in this section.

If the relief valve still does not function properly, replace the

relief valve.

Installation

1. Install fittings into valve.

2. Position the valve assembly on the mounting plate and

secure with three capscrews, washers and nuts.

3. Connect all hoses to the control valve.

4. Start the engine and release the air in the hydraulic lines

by operating each hydraulic function several times in

both directions.

5. Check for leaks and fill the reservoir, if required.

Outrigger Control Valve

Removal

NOTE: On units with standard outriggers, one outrigger

valve is used. On units with independent

outriggers, two outrigger valves are used. Removal

instructions for both valves are the same except

where noted.

1. Stop the engine and engage the parking brake. Place

chocks under the wheels.

2. Disconnect the battery cables from the battery. For

safety, disconnect the negative (-) cable first.

Problem Probable Cause Remedy

Can’t get pressure

Poppet D, E, or K stuck open or

contamination under seat. (Figure 4-20).

Check for foreign matter between poppets

D, E, or K and their mating parts. Parts

must slide freely.

Erratic Pressure

Pilot poppet seat damaged.

Poppet C sticking in D. (Figure 4-20)

Replace the relief valve.

Clean and remove surface marks for free

movement.

Pressure setting not correct

Normal wear. Lock nut & adjusting screw

loose.

Adjust pressure.

Leaks

Damaged seats.

Worn O-ring.

Parts sticking due to contamination.

Replace relief valve.

Replace relief valve.

Replace relief valve.

FIGURE 4-19

a0973

Sensing Hole

Poppet

Reference Only

Loading...

Loading...