GROVE 11-59

CD3340B/YB4411 STRUCTURAL

11

Published 04/07/2015 Control # 569-00

Installation

1. Using a suitable solvent, clean the holes in the bearing

plate on the main frame. Remove the residue with

compressed air. Clean all dirt from the bearing plate.

2. Put the mast bearing (30, Figure 11-142) in place on the

bearing plate.

3. Install the 24 capscrews (31) and structural washers (6)

to fasten the mast bearing (30) to the bearing plate.

4. Figure 11-140 shows the order for tightening the

capscrews. Each capscrew must first be tightened to a

torque of 384 Nm (282 lb-ft) and then loosened a small

amount. Next, tighten the bolts again to a torque of 384

Nm (282 lb-ft).

5. Make sure the top surface of the mast bearing and the

bottom surface of the mast base are clean.

6. With a hoist, lower the mast into position over the mast

bearing. Install 22 capscrews (18) and structural

washers (19).

7. Figure 11-140 shows the order for tightening the bolts.

Each bolt must first be tightened to a torque of 245 Nm

(180 lb-ft) and then loosened a small amount. Next,

tighten the bolts again to a torque of 245 Nm (180 lb-ft).

8. Install swivel stop (39, Figure 11-142) to the hydraulic

swivel. Attach swivel to mast base with three capscrews

(53) and lockwashers (1).

9. Connect the hydraulic lines and hoses to the hydraulic

swivel.

10. Install lift cylinder to mast.

11. Install boom assembly to mast. See Installation earlier in

this Section.

Swing Gearbox and Pinion

Maintenance

Gearbox

The swing gearbox has a worm gear set which rotates on

taper roller bearings. The gears and bearings are given

lubrication by grease in the gearbox. Gaskets inhibit external

leakage of the grease.

Keep the gearbox filled with grease. See Section 5,

Preventive Maintenance.

Swing Gear/Pinion

The swing pinion and ring gear must be lubricated at regular

intervals. See Section 5, Preventive Maintenance for

maintenance intervals and instructions.

Adjustments

Checking Backlash

1. Remove the front cover to expose the swing pinion and

ring gear.

• Rotating gears can cause injury. Keep hands clear of

rotating pinion and ring gear while mast is rotating.

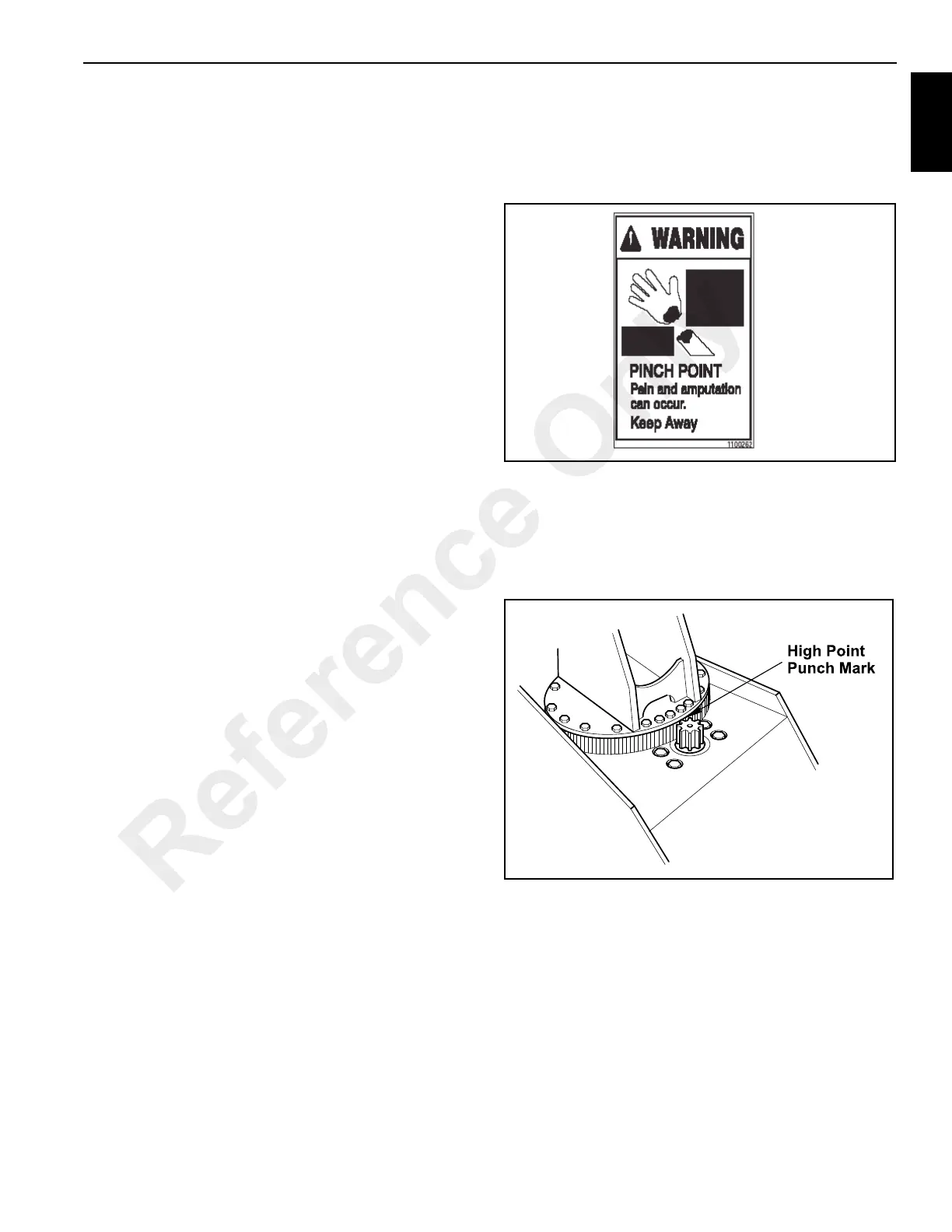

2. Start the engine and rotate the mast until the high point

(marked with a punch-mark on the edge of the mast

base plate) is in alignment with the pinion. See

Figure 11-143.

3. Using a feeler gauge, check the backlash between the

gear and pinion. There should be no clearance between

the swing gear tooth and the pinion tooth. If there is any

clearance, adjust the backlash.

Adjusting Backlash

NOTE: Be sure the swing gear and pinion are aligned at

the high spot on the swing gear.

Reference Only

Loading...

Loading...