Grove Published 3-25-2020, Control # 595-10 4-7

GRT8100 OPERATOR MANUAL SET-UP AND INSTALLATION

INSTALLING WEDGE AND SOCKET

1. Inspect wedge and socket. Remove rough edges and

burrs.

2. Seize wire rope end using soft or annealed wire or

strand. If end of rope is welded, welded end should be

cut off. This allows distortion of the rope strands, caused

by the bend around the wedge, to adjust themselves at

the end of the line.

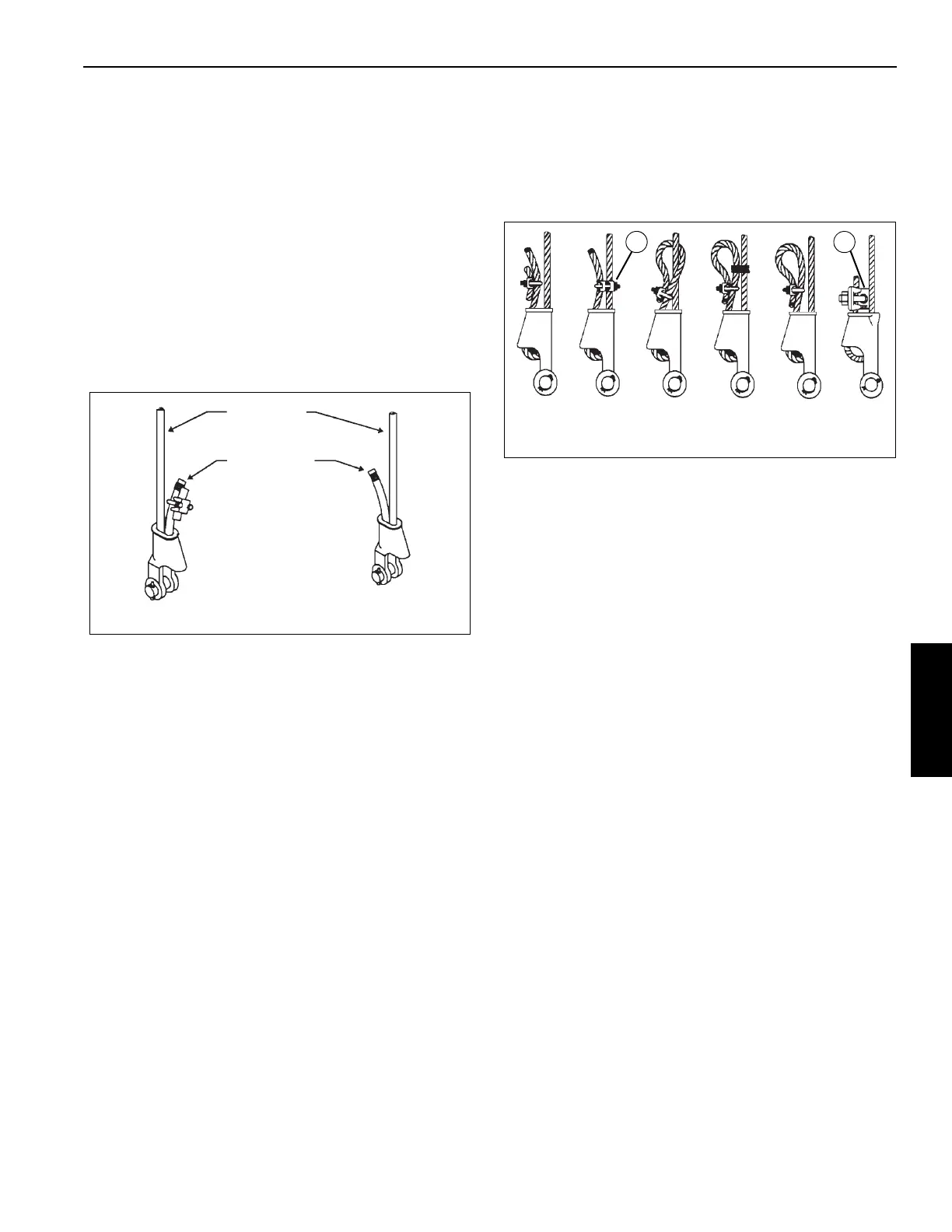

3. Make sure live end side (Figure 4-9) of rope is directly in

line with ears of socket and direction of pull to which the

rope will be subjected. If rope is loaded into socket

incorrectly, under a load the rope will bend as it leaves

the socket. The edge of the socket will wear into the rope

causing damage and eventual failure.

4. Insert wire rope end in socket, form a loop in the rope,

and route rope back through socket allowing the “dead”

end to protrude from the socket. Ensure dead end of the

rope is long enough to apply end treatment after wedge

is seated.

5. Insert wedge in loop. Pull live end of rope until wedge

and rope are snug inside socket. It is recommended

wedge be seated inside socket to properly secure the

wire rope using the crane’s hoist to first apply a light load

to the live line.

6. After final pin connections are made, increase loads

gradually until wedge is properly seated.

7. Wire rope and wedge must be properly secured inside

socket before placing crane into lifting service. It is the

wedge that secures the wire rope inside the socket. The

dead-end treatment is used to keep wedge from

becoming dislodged from socket should the rope

suddenly become unloaded from the overhaul ball or

hook block striking the ground, etc.

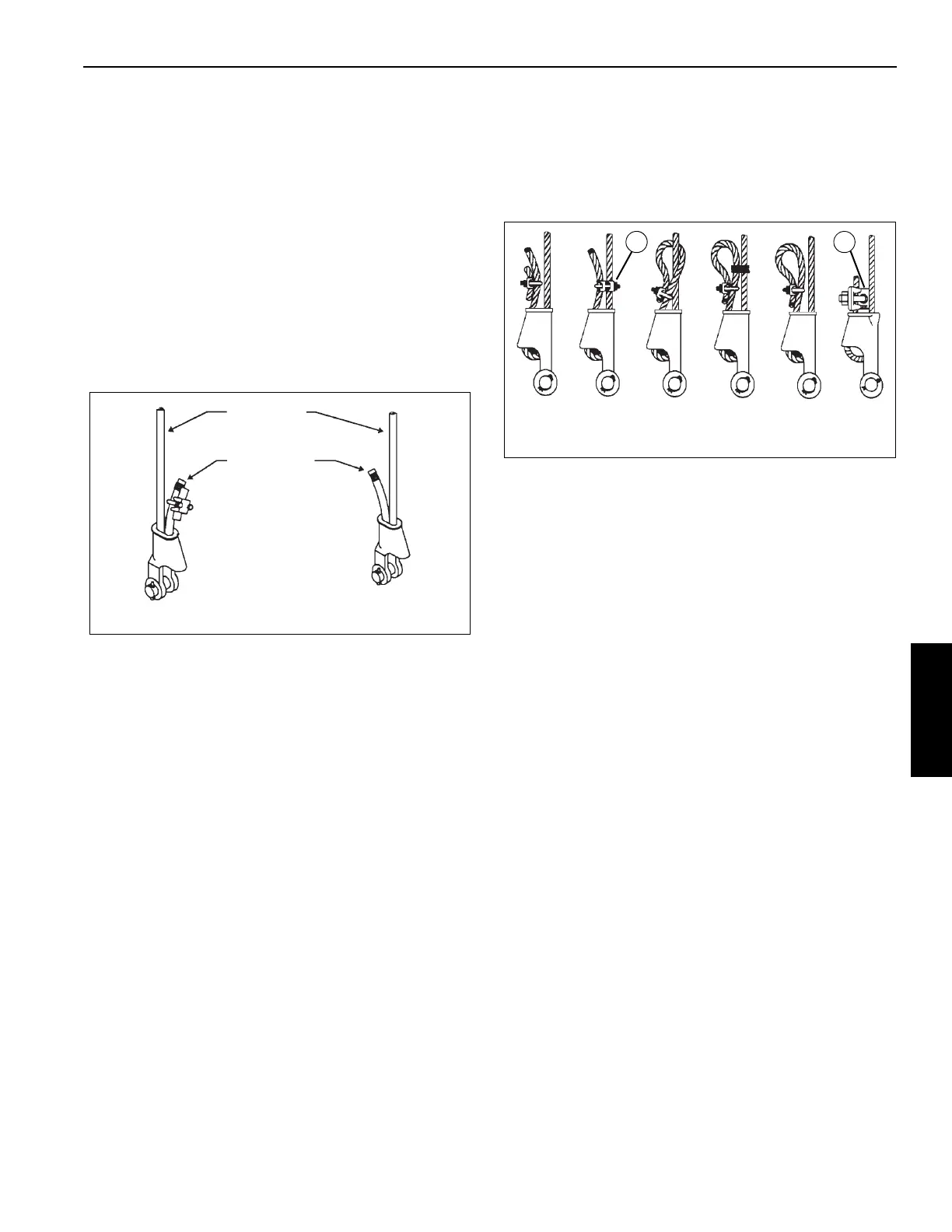

Figure 4-10 shows methods for securing dead-ends of wire

ropes in a wedge socket assembly. While the loop-back

method (C, D, E) is acceptable, take care to prevent the loop

becoming entangled with tree branches and other

components during crane transport, or the anti-two block

system and other components during crane operation.

Of methods shown, Grove prefers method A or F be used on

Grove cranes, i.e., clipping a short piece of wire rope to the

dead-end or using a commercially available specialty clip (1)

or wedge (2). It is recommended the dead-end tail length be

a minimum of 6 rope diameters, but not less than 15.2 cm

(6 in) for standard 6 to 8 strand ropes and 20 rope diameters,

but not less than 15.2 cm (6 in) for rotation resistant wire

ropes.

When using method A, place a wire rope clip around the

dead end by clamping a short extra piece of rope to the rope

dead end. DO NOT CLAMP LIVE END. U-bolt should bear

against the dead end. Clip saddle should bear against the

short extra piece. Torque U-bolts to values listed in

Table 4-1.

NOTE: Use of swivels is not allowed with non-rotation

resistant wire ropes.

Other sources for information with which crane users should

be familiar and follow is provided by the American Society of

Mechanical Engineers, American National Standard,

ASME B30.5, latest revised. ASME (formerly ANSI) B30.5

applies to cableways, cranes, derricks, hoists, hooks, jacks,

and slings.

It states, in section 5-1.7.3, “(c) Swagged, compressed, or

wedge socket fittings shall be applied as recommended by

the rope, crane or fitting manufacturer.” Wire ropes are

addressed in ASME B30.5, section 5-1.7.2, ROPES. It

states, in pertinent part, “(a) The ropes shall be of a

construction recommended by the rope or crane

manufacturer, or person qualified for that service.” Additional

information is published by the Wire Rope Technical Board in

Wire Rope Users Manual, latest revision.

Incorrect

Correct

Dead End

Live End

5337

FIGURE 4-9

Loading...

Loading...