Grove Published 4-09-2021, Control # 364-11 3-41

RT765E-2 OPERATOR MANUAL OPERATING CONTROLS AND PROCEDURES

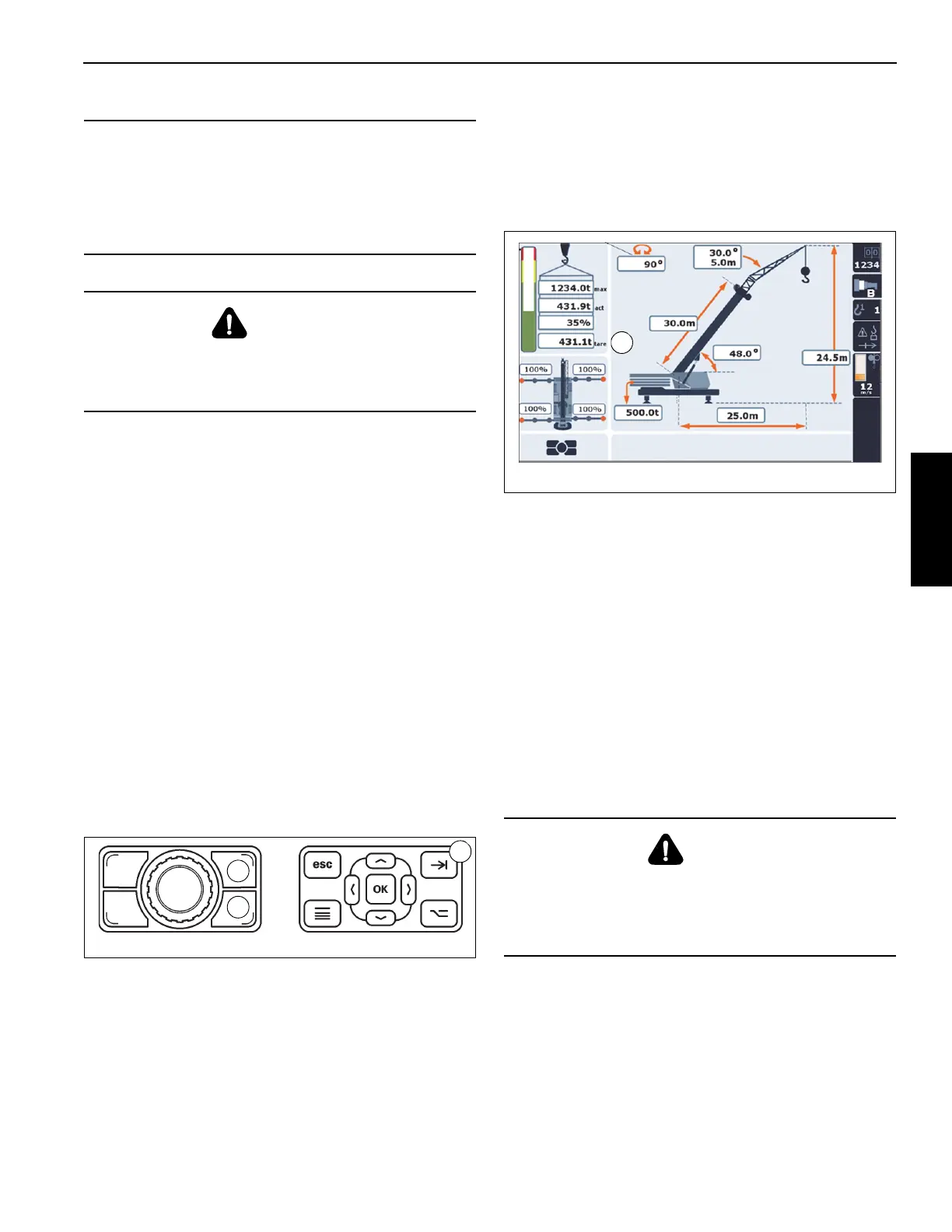

An Anti-Two Block Device is also incorporated into the

system to prevent the hook block or overhaul ball from

coming into contact with the boom nose or boom extension.

This condition will cause a lockout of hoist up, boom down,

and telescope out, and also provide a visual and an audible

alarm.

Refer to the RCL Operator Handbook for more detailed

information on the function of the RCL system.

Using the Tare Function

The tare function is not shown on the RCL Display Module

(RDM) at crane startup.

To show the tare function, do one of the following:

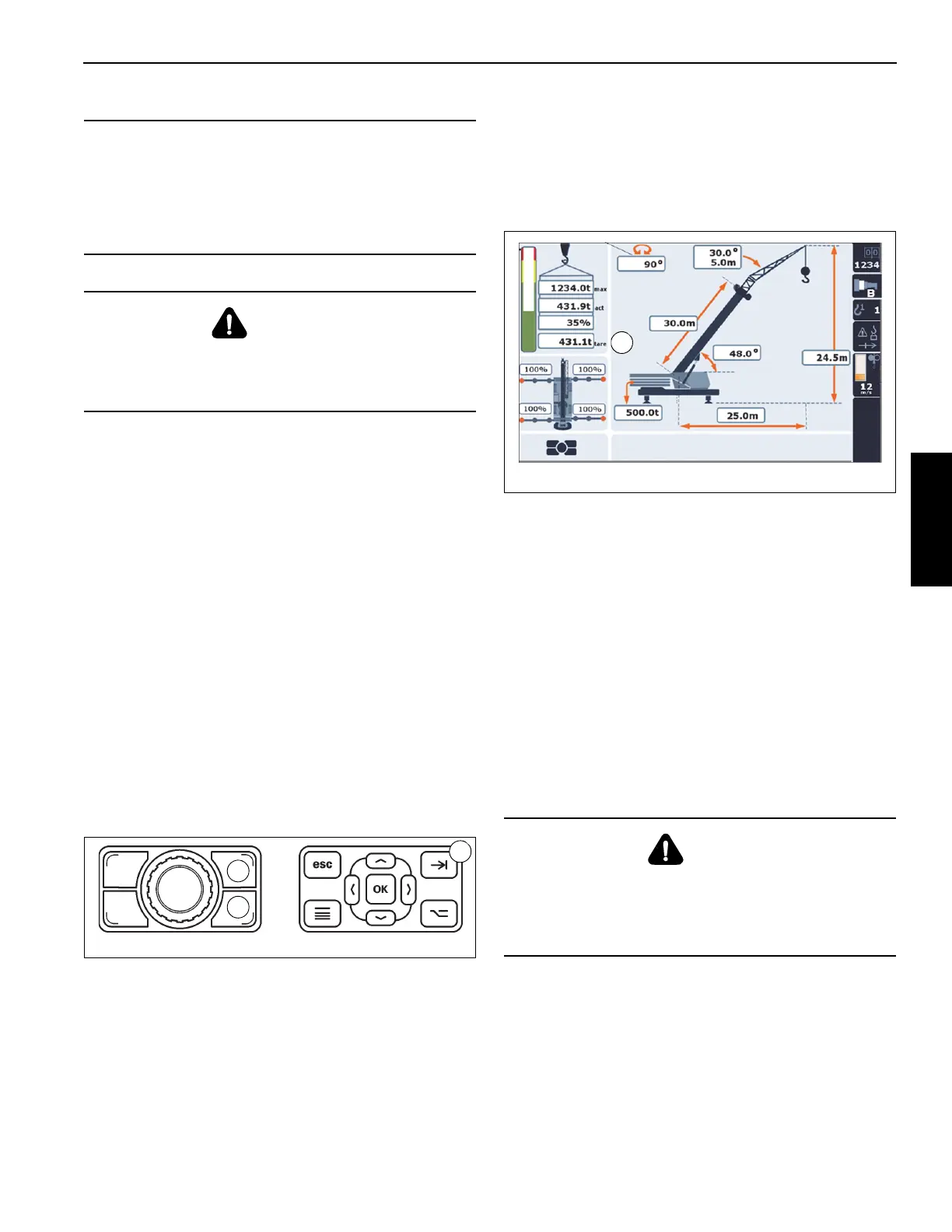

• Press the Screen Toggle Button (1, Figure 3-20) at the

Jog Dial to select the RDM screen control.

From the RCL Setup Screen, press the Tab Button (2).

- or -

• Press the Tab Button (3, Figure 3-20) on the RDM

Navigation Control Pad.

The tare weight (1. Figure 3-21) is shown below the

percentage of the actual versus maximum percent load. The

tare weight value equals the actual weight value until the tare

weight is zeroed out. The operator sets the tare weight to

zero by pressing the Tab Button on either the Jog Dial or the

RDM Navigation Control Pad.

If the Operator changes the Load Chart Code Number, the

tare weight will be reset to equal the current Actual Weight.

To disable the tare function, the operator must switch power

off and back on using the Ignition Key Switch.

NOTE: The tare function does not change nor override the

value of the Actual Load, and does not affect the

Rated Capacity Limiter (RCL) and its function

lockouts.

Control Lever Lockout System

The control lever lockout system consists of hydraulic

solenoid valves (located in the directional control valves)

which are in series between the hydraulic remote control

valves in the cab and the pilot-operated directional control

valves. When the valves are actuated, they prevent pilot flow

between the hydraulic remote control valve in the cab and

the appropriate directional control valve. The valves are

activated in such a manner as to prevent worsening the

condition, i.e. boom down, telescope out, or hoist up. The

control lever lockout system is used with the anti-two-block

system or the Rated Capacity Limiter (RCL) system.

Stowing and Parking

When parking the crane, do the following:

1. Park the crane on a stable surface.

2. Remove the load from the hook.

3. Stow the swingaway boom extension, if erected.

CAUTION

Possible Machine Damage!

When defining virtual wall(s), always allow a safe working

distance to any obstacles. Never work outside a safe

working area as defined by common practice, standards,

and manuals.

WARNING

Risk of Unexpected Operation!

There are no machine cutouts associated with the swing

angle set limitation or the work area definition features.

DANGER

Tipping Hazard!

Never park the crane near holes, or on rocky or extremely

soft surfaces. This may cause the crane to overturn,

resulting in injury to personnel.

Loading...

Loading...