Grove Published 4-09-2021, Control # 364-11 4-3

RT765E-2 OPERATOR MANUAL SET-UP AND INSTALLATION

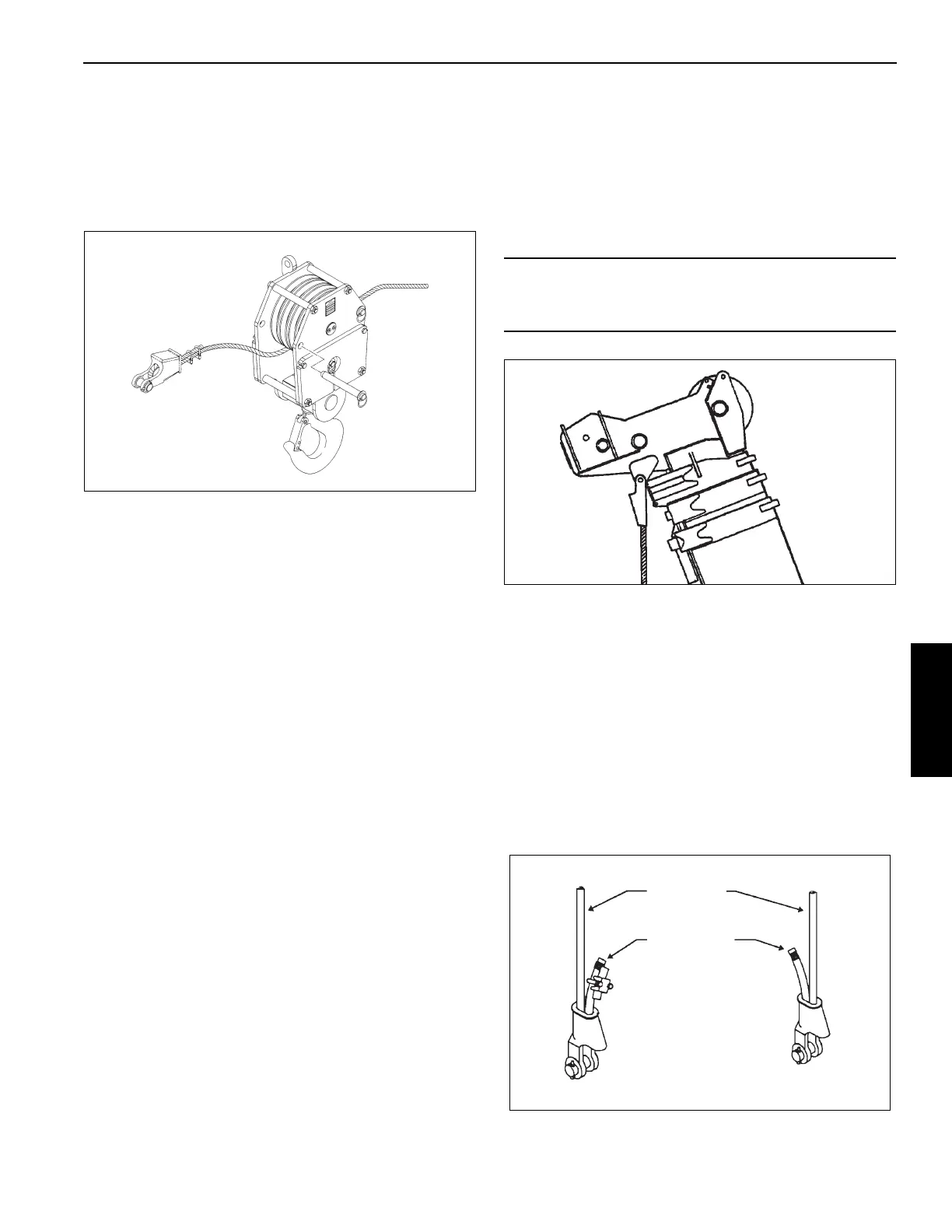

reeving (part line) is possible with the boom nose and hook

block (Figure 4-7) and (Figure 4-8). This reeving should be

accomplished by a qualified rigger using standard rigging

procedures.

In order to quick reeve the hook block without removing the

wedge socket on the end of the cable refer to Figure 4-4.

Boom Cable Reeving

When reeving the boom, always reeve the main hoist wire

rope through the rope grab; if also reeving the auxiliary hoist

rope, reeve the auxiliary hoist rope outside of the rope grab.

DEAD-END RIGGING/WEDGE SOCKETS

Wedge socket assemblies are popular rigging accessories

and have been successfully used for decades to terminate

wire ropes on mobile cranes. A wedge socket assembly is

easily installed and dismantled but it must be installed and

used correctly. It is essential to use only a wedge and socket

of the correct size for the rope fitted. Failure to do so may

result in the rope pulling through the fitting.

Since state and local laws may vary, alternate attachment

methods may be necessary depending upon work

conditions. If alternate methods are selected, the user is

responsible and should proceed in compliance with the

regulations in force. If there are any questions, contact your

local Grove Distributor or Manitowoc Crane Care

Do not mix components from different manufacturers. The

selection, installation and use of a wedge socket assembly

must be in accordance with the requirements of the wedge

socket manufacturer and the wire rope manufacturer upon

whose wire rope the wedge socket assembly will be used.

Grove specifies the size, type, class and line pulls for wire

rope, predominately rotation resistant wire rope, and rigging

accessories such as overhaul balls and hook blocks for use

with each new crane that it manufactures. Other wire ropes

and rigging accessories are available from various vendors.

Different wire rope manufacturers have differing

requirements for the construction, handling, cutting, seizing,

installation, termination, inspection and replacement of the

wire ropes they produce. Their advice should be sought for

each specific type of wire rope a crane user intends to install

on a mobile crane.

When assembly is complete, raise the boom to a working

position with a load suspended to firmly seat the wedge and

rope into the socket before the crane is used operationally.

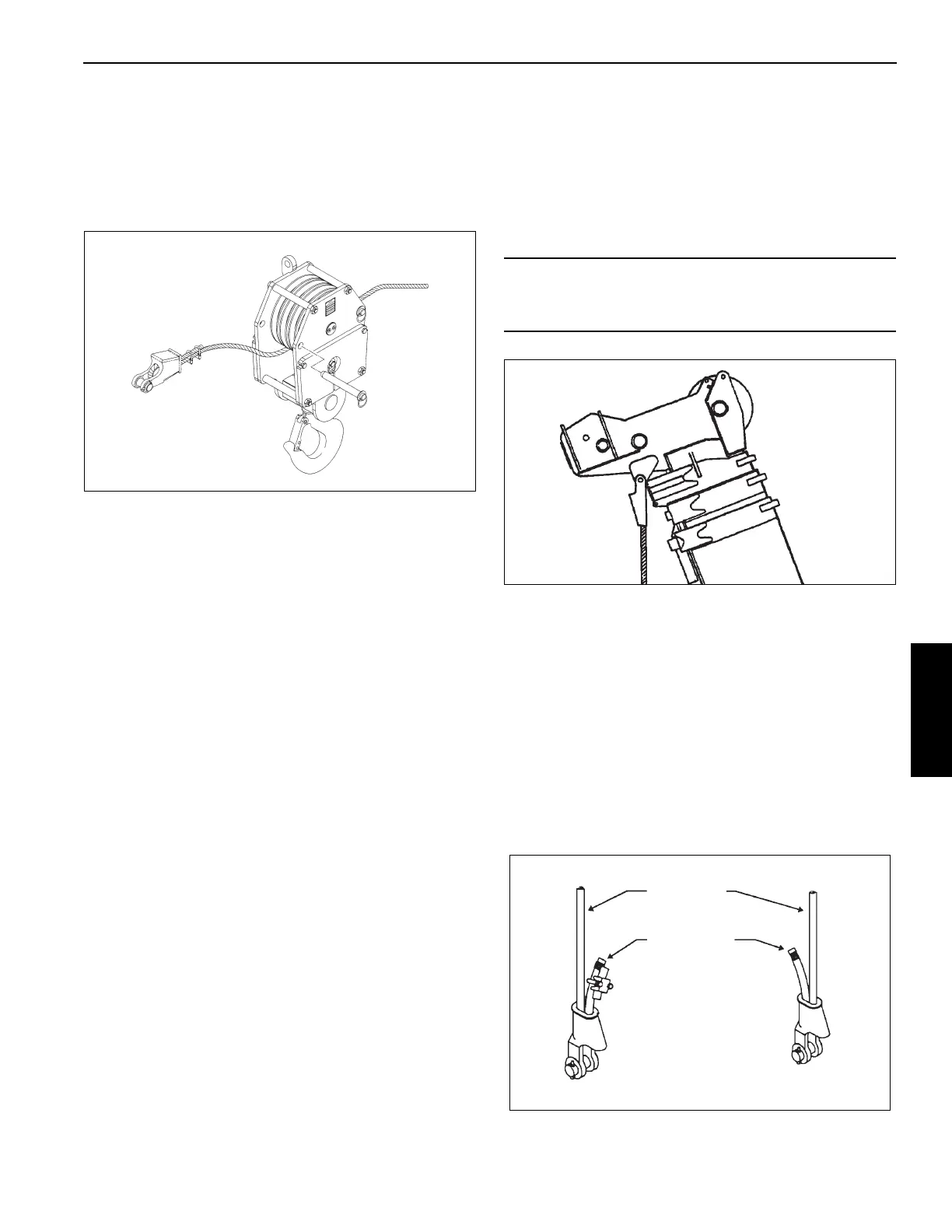

When anchoring the socket to the boom, ensure the flat face

of the socket is in position, as shown, toward the boom

sections (Figure 4-5).

INSTALLING WEDGE AND SOCKET

1. Inspect the wedge and socket. Remove any rough

edges and burrs.

2. The end of the wire rope should be seized using soft, or

annealed wire or strand. If the end of the rope is welded,

the welded end should be cut off. This will allow the

distortion of the rope strands, caused by the bend

around the wedge, to adjust themselves at the end of the

line.

CAUTION

If the socket is not positioned with the flat face toward the

boom sections, structural damage will occur.

Wrong

Right

Dead End

Live End

5337

FIGURE 4-6

Loading...

Loading...