National Crane 3-29-2018 Control # 610-00 6-7

NBT40-1 SERIES OPERATOR MANUAL SET-UP

WEDGE SOCKETS

To install a wedge socket:

• Make sure the wedge socket is the proper size for

1

the

rope.

• Do not mix components of different wedge socket

manufacturers.

• The wedge socket must meet the requirements of the

wedge socket and wire rope manufacturers.

State and local laws may vary and require different

attachment methods depending upon work conditions. The

user is responsible for alternate attachment methods.

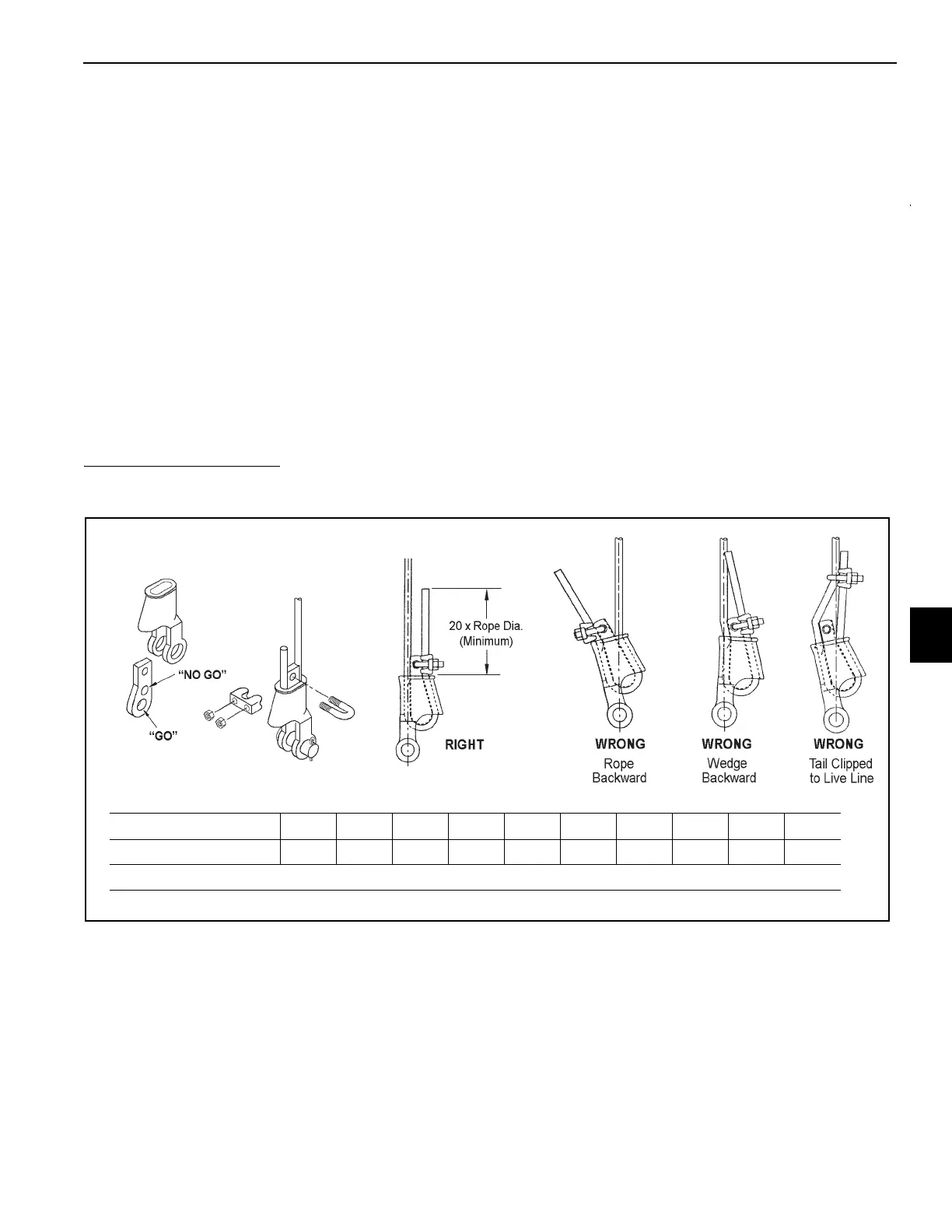

Terminator Wedge Installation

Terminator wedge socket is the preferred type of socket

(Figure 6-4). Other wedge socket types are shown on

page 6-7.

To attach a terminator wedge, use the following procedure:

1. Match the socket, wedge, and clip to the wire rope and

size the rope with the go and no go hole in the socket.

• The wire rope must pass through the “go” hole and

not pass through the “no go” hole.

• If the wire rope passes through the “no go” hole, the

wedge is the wrong size.

• If the wire rope does not pass through the “go” hole,

the wedge is the wrong size.

2. Align the live end of rope, with center line of pin.

3. Secure dead end section of rope.

4. Tighten nuts on clip to recommended torque.

5. Do not attach dead end to live end or install wedge

backwards.

6. Use a mallet to seat Wedge and Rope as deep into

socket as possible before applying first load.

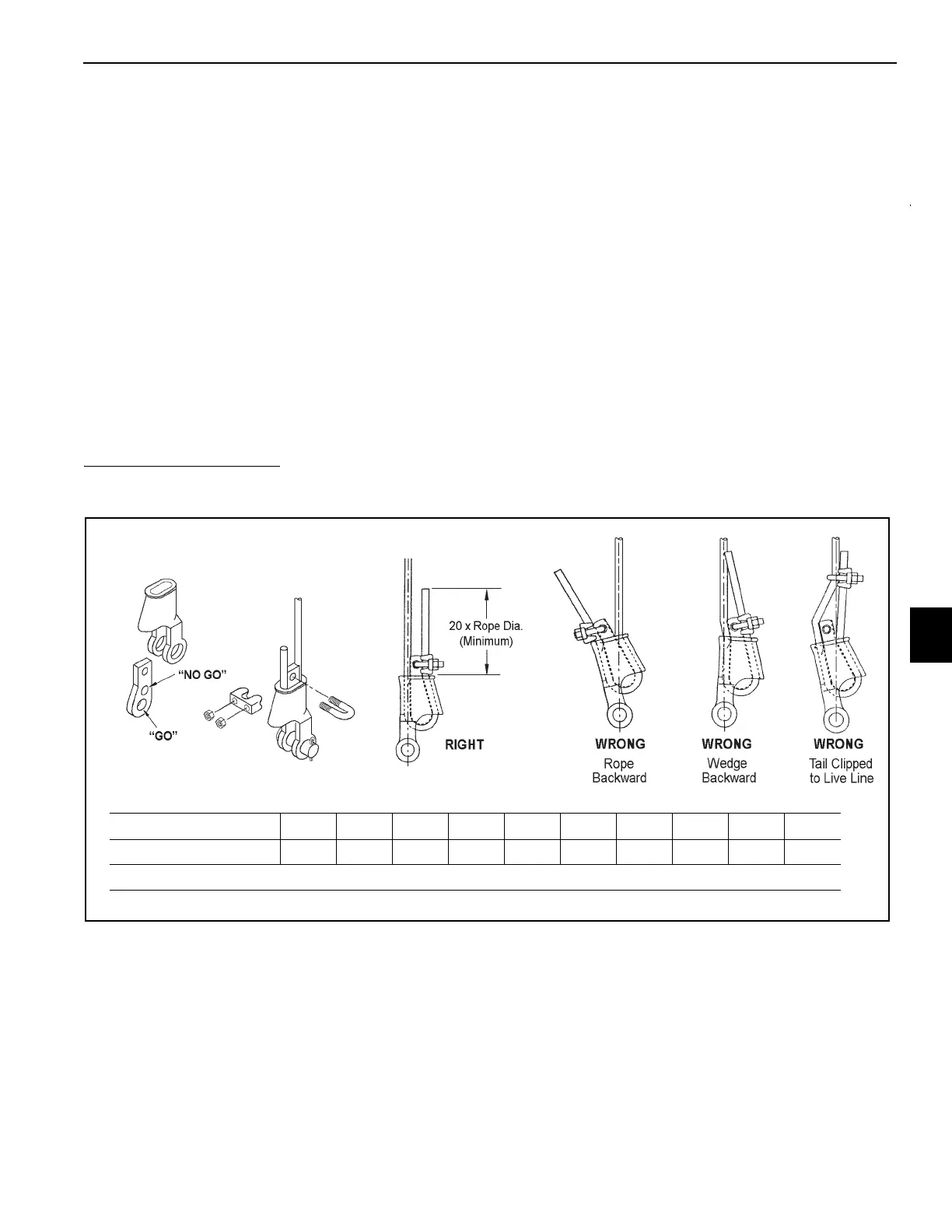

Wedge Socket Installation

1. Inspect the wedge and socket. Remove any rough

edges and burrs.

2. The end of the wire rope should be seized using soft, or

annealed wire or strand. If the end of the rope is welded,

the welded end should be cut off. Do not weld on size

6X37 rope. This will allow the distortion of the rope

strands, caused by the bend around the wedge, to

adjust themselves at the end of the line. Refer to

SECTION 1 - INTRODUCTION in the Service Manual

for wire rope procedures.

3. Make sure the live-end (Figure 6-5) of the rope is directly

in line with the ears of the socket and the direction of pull

to which the rope will be subjected. If the rope is loaded

into the socket incorrectly, under a load the rope will

bend as it leaves the socket, and the edge of the socket

1.

FIGURE 6-4

Torque Value Table

Rope Size (inches) 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1-1/8 1-1/4

Torque ft/lbs 45 65 65 95 95 130 225 225 225 360

Torque values shown are based upon clean dry threads free of lubrication.

Terminator Wedge Socket

Loading...

Loading...