7-2 3-29-2018 Control # 610-00

LUBRICATION NBT40-1 SERIES OPERATOR MANUAL

products. Where questions arise, contact your National

Crane Distributor or Manitowoc Crane Care.

Arctic Conditions Below -9°C (15°F)

In general, petroleum based fluids developed especially for

low temperature service may be used with satisfactory

results. However, certain fluids, such as halogenated

hydrocarbons, nitro hydrocarbons, and phosphate ester

hydraulic fluids, might not be compatible with hydraulic

system seals and wear bands. If you are in doubt about the

suitability of a specific fluid, check with your authorized

National Cranes distributor or Manitowoc Crane Care.

NOTE: All fluids and lubricants may be purchased by

contacting the Manitowoc Crane Care Parts

Department.

Regardless of temperature and oil viscosity, always use

suitable startup procedures to ensure adequate lubrication

during system warm-up.

Chassis Grease

Lubricating grease of proper consistency is to be applied

periodically at relatively frequent intervals with grease guns

through grease fittings. Minimum apparent viscosity of

300 SUS (Saybolt Universal Seconds) at 38°C (100°F)

is recommended.

Low Temperature Grease

This special grease for low temperature remains plastic at

-51° C (-60° F) with melting point of 138°C (280°F). The

grease is a heavy duty extreme pressure type lubricant

(Lubricate Low Temp or equal).

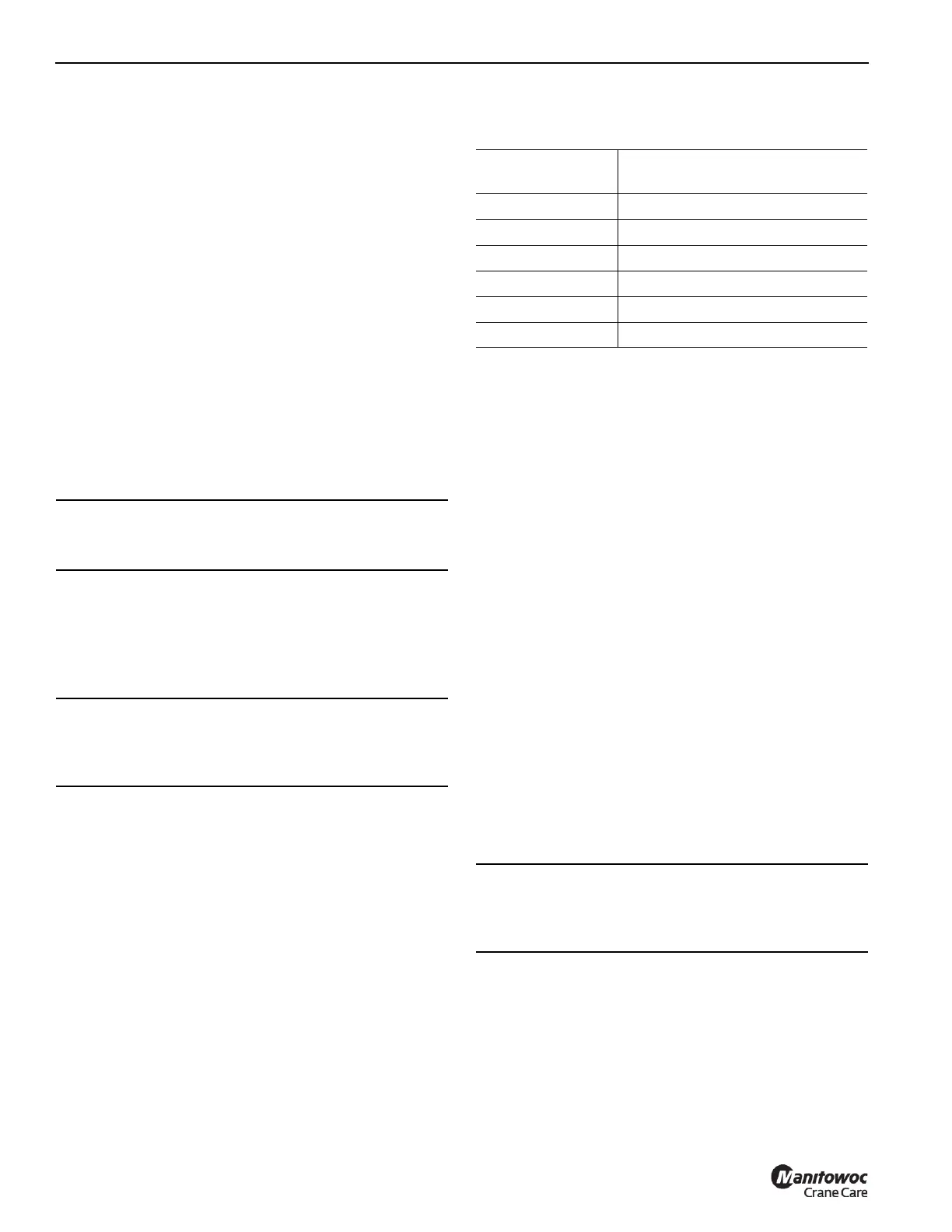

Extreme Pressure Multipurpose Gear

Lubricant (EPGL)

This gear lubricant is compounded to achieve high load

carrying capacity and meet the requirements of either API-

GL-5 or MIL-L-2105C. Unless otherwise specified,

SAE 80W-90 viscosity may be used for year round service.

Low temperature usage is restricted as follows:

Open Gear Lubricant

This is a special high-graphite adhesive lubricant that helps

to eliminate fretting corrosion, is water resistant, and forms a

dry lubrication film which does not attract dust. Lubricant

meets NLGI Class 1-2 specifications.

Antifreeze/Coolant (for Cab Heater)

The standard antifreeze/coolant filled from the factory is

intended to provide protection against freeze-up down to

-36° C (-34° F) and boil-over up to 129° C (265° F) using a

15 psi pressure cap.

Anti-wear Additives

Excessive wear in the system may cause a loss in volumetric

efficiency and cause shutdowns for maintenance. An

efficient anti-wear oil protects the components against

rusting, resists oxidation and helps prevent wear.

Hydraulic Oil

Oil in a hydraulic system serves as the power transmission

medium, system lubricant and coolant. Selection of the

proper oil is essential to ensure satisfactory system

performance and life. The most important factors in selecting

an oil for hydraulic service are viscosity and anti-wear

additives.

NOTE: When operating the equipment in temperatures

-9°C (15°F) and below, follow the procedures in

the section titled “Arctic Conditions Below -9°C

(15°F)” on page-2.

CAUTION

Do not use air pressure devices to apply chassis grease

otherwise damage to sealed fittings may result.

CAUTION

The multipurpose grease installed during manufacture is

of a lithium base. Use of a non-compatible grease could

result in damage to equipment.

SAE Viscosity

Number

Minimum Ambient Temperature

C (F)

75W -40°C (-40°F)

80W -2°C (-15°F)

85 -12°C (+10°F)

90 -7°C (+20°F)

140 +5°C (+40°F)

250 +10°C (+50°F)

CAUTION

Operation of the equipment with incorrect hydraulic oil in

sub freezing temperature (below 0° C,32° F) can cause

damage to the extend cylinder.

Loading...

Loading...