SWING NBT40 SERVICE MANUAL

6-14 Published 8-01-2017 Control # 287-11

Slew Potentiometer Adjustment

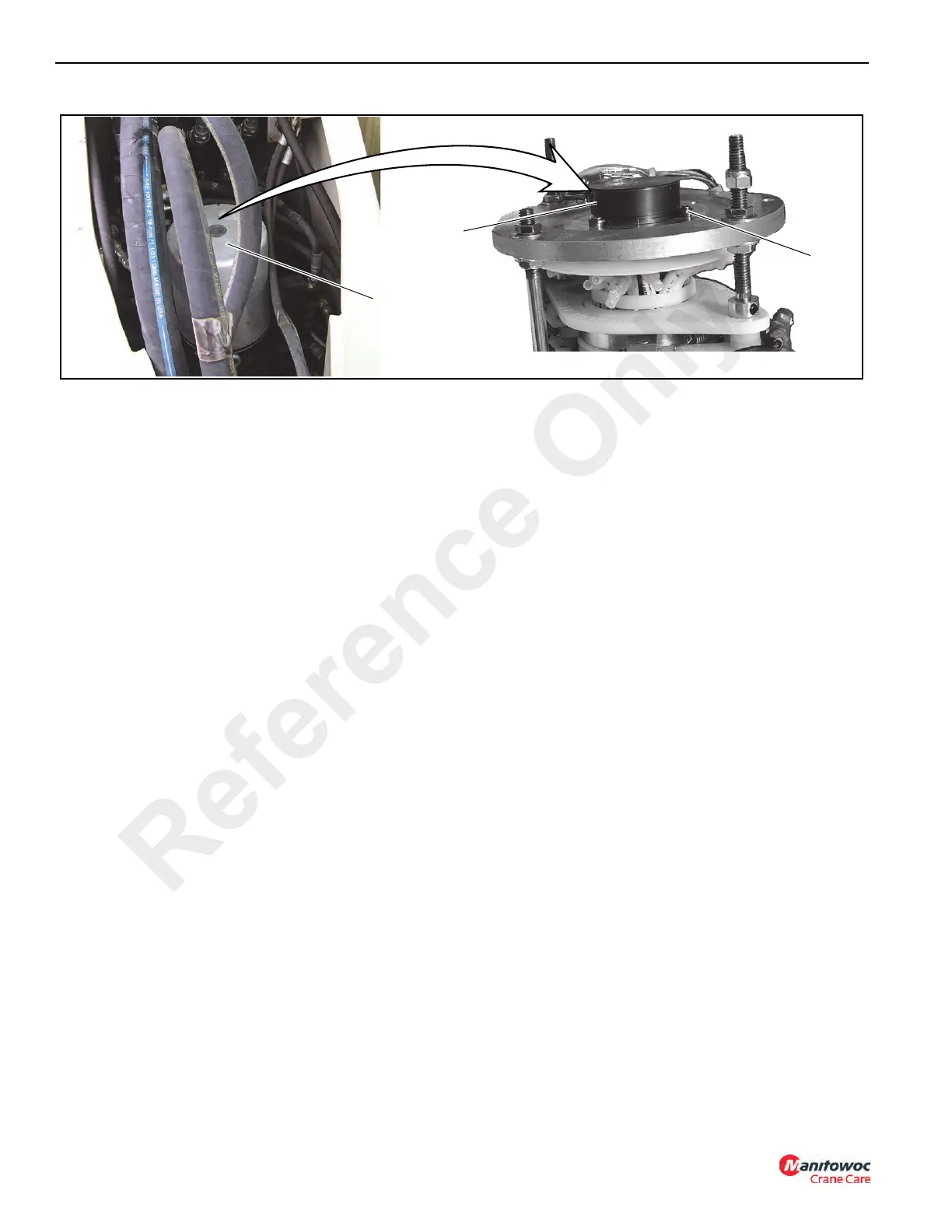

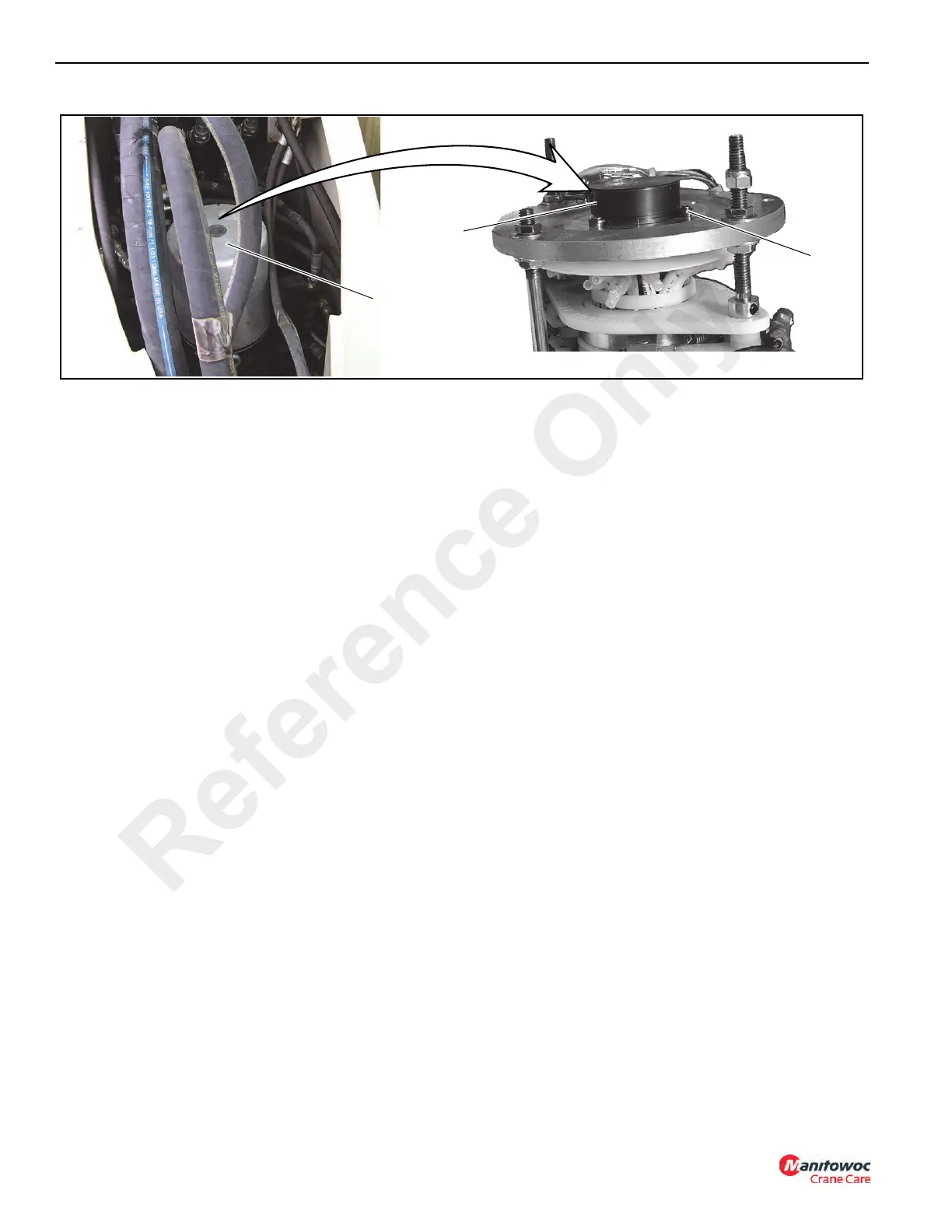

The slew potentiometer is a component of the hydraulic and

electric swivel assembly which is mounted inside the

superstructure turret. The top part of the swivel assembly is the

electrical swivel section (1,Figure 6-11) and contains the slew

potentiometer (2, Figure 6-11).

1. Remove the cover from the electrical swivel section (1).

2. Using the cab controls to rotate the turret over the front

and set the swing brake.

3. Set the RCL console to read slewing angle as follows:

NOTE 1: Refer to the mentor QVGA Load Moment

Indicator Manual for detailed instructions.

a. Complete the RCL console setup according to the

crane’s current operating configuration.

b. Press limits LIM.

c. Press the OK button.

d. Toggle down to SLEW and press the ok button to

display the slew angle work area definition limits.

4. Remove the electrical swivel cover.

5. Release the swing brake. Swing the turret about 10° to

the right (clockwise). Slowly swing back to over the front

and set the swing brake.

NOTE: If the turret swings past the over the front position,

step 4 must be repeated.

6. Loosen the three screws (3,

Figure 6-11) that secure the

slew potentiometer to the mounting plate.

7. Rotate the body of the slew potentiometer (2,

Figure 6-11) until the slew angle indicates 0.6° ± 0.1°.

8. Tighten the three screws (3,

Figure 6-11) to secure the

slew potentiometer to the mounting plate. Install the

electrical swivel cover.

9. Disengage the swing brake and swing approximately

10° to the left (counterclockwise). Slowly swing back to

over the front and set the swing brake.

NOTE: If the turret swings past the house lock pin engaged

position, step 8 must be repeated.

10. If the angle indicated on the console does not exceed

± 1.0°, proceed to step 10. If the indicated angle

exceeds ± 1.0°, return to step 4.

11. Release the swing brake and swing approximately 10°

to the right (clockwise). Slowly swing back to over the

front and set the swing brake.

NOTE: If the Turret swings past the over the front position,

step 10 must be repeated.

12. If the angle indicated on the console does not exceed

± 1.0°, proceed to step 12. If the indicated angle

exceeds ± 1.0°, return to step 3.

13. Release the swing brake and swing approximately 10°

to the left (counterclockwise). Slowly swing back to over

the front and set the swing brake.

Testing

Activate the crane and check for proper function.

NOTE: If the turret does not turn freely after bearing and

pinion replacement, contact your local distributor.

SWING LOCK

The swing 360° lock holds the turret in place preventing any type

of movement in either a counterclockwise or clockwise direction.

This is a mechanical lock which is engaged and disengaged by

a cable assembly connected to the swing lock foot pedal located

in the operator’s cab.

Reference Only

Loading...

Loading...