HYDRAULIC SYSTEM NBT40 SERVICE MANUAL

2-12 Published 8-01-2017 Control # 287-11

RELIEF VALVE PRESSURE SETTING

PROCEDURES

Description

The valves in the hydraulic system must be properly

adjusted to protect a component, circuit, or system from over

pressurization (relief valves) and ensure the components

receive the appropriate pressure and flow.

Maintenance

Relief valves are checked and adjusted by causing a given

circuit to reach its prescribed pressure limit (stall). At this

point the relief valve opens, returning hydraulic oil to the

reservoir. Hydraulic motor circuits can be stalled by

preventing rotation of the motor shaft prior to actuating the

control valve. Cylinder circuits can be stalled by extending or

retracting a cylinder to its limit of travel.

Correct relief valve adjustment is mandatory for proper

functioning of a hydraulic circuit. Only qualified technicians

using the correct equipment should make pressure

adjustments when pressure adjustments are needed.

NOTE: Use an accurate 0 to 34,500 kPa (0 to 5000 psi)

pressure gauge when adjusting relief valves. To

adjust a relief valve, turn the adjustment screw (in

to increase or out to decrease) until the proper

setting is reached.

Release the control lever after taking each reading

and while making adjustments. When the proper

pressure setting has been attained, tighten the

adjustment screw locknut and recheck the

pressure.

It is only necessary to hold hydraulic pressure long

enough (usually a few seconds) to gain an

accurate reading. Do not overload the hydraulic

circuits for long periods of time.

Reservoir oil temperature is to be 140° - 160°F.

Preparation

• Run the engine until the hydraulic oil temperature

reaches a minimum of 49°C - 60°C (120°F - 140° F).

• Shut down the engine.

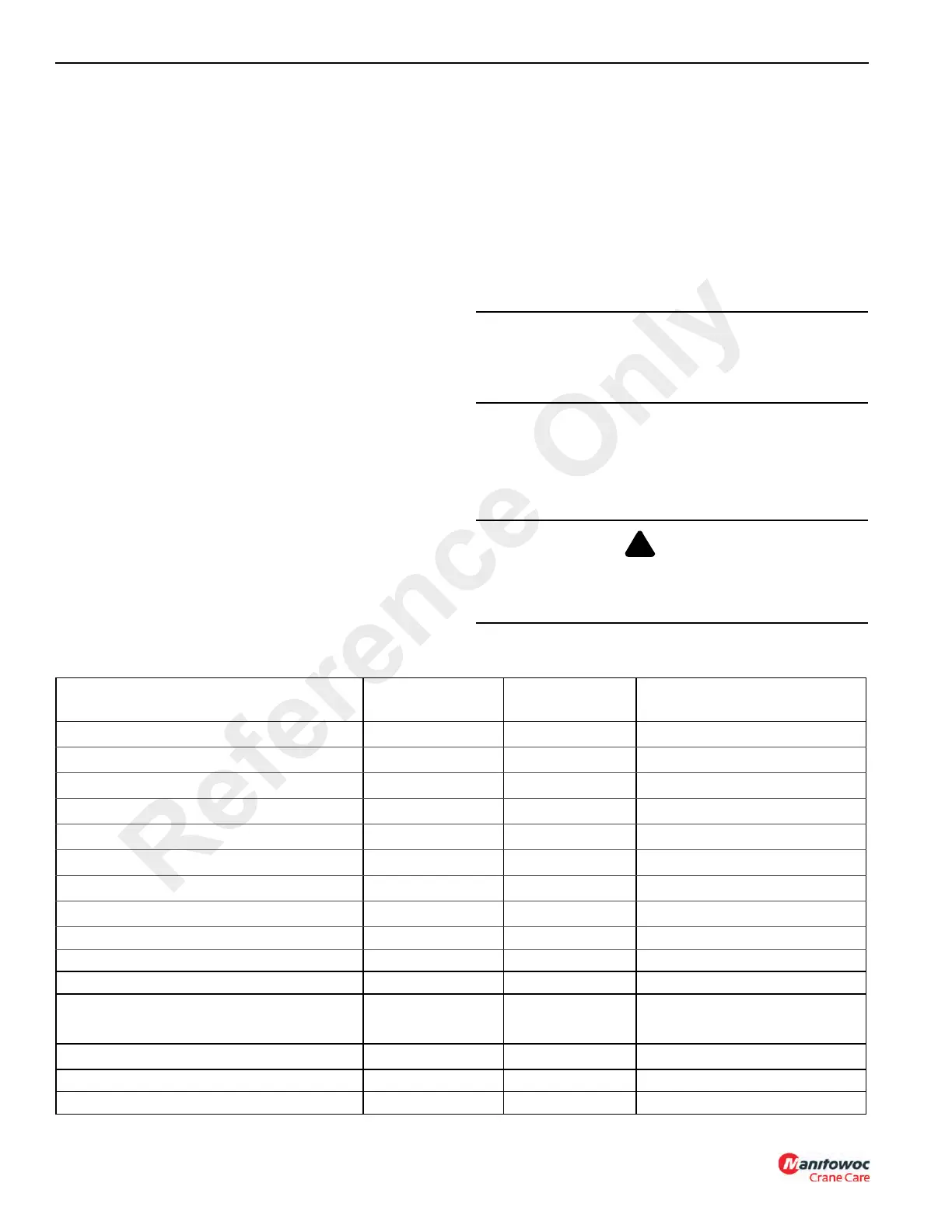

Relief Valve Pressure Settings

CAUTION

Do not overtighten the adjustment screw or locknut.

Do not hold the relief valve open for more than one minute

at a time.

DANGER

Do not attempt to loosen the fittings in pressurized lines or

while the hydraulic pumps are in operation or personnel

injury could result.

Valve To Be Set

Pressure Setting

kPa (PSI)

Tolerance kPa

(PSI)

Valve Adjustment Location

Telescope Retract Relief 15513 (2250) ±689 kPa (100 psi) Main Control Valve

Telescope Extend Relief 18615 (2900) ±689 kPa (100 psi) Main Control Valve

Load Sense Relief 28785 (4175) ±344 kPa (50 psi) Main Control valve

Outrigger Relief (Flow Control Valve) 20684 (3000) ±689 kPa (100 psi) Front Outrigger Box

Boom Up Relief 24821 (4550) ±344 kPa (50 psi) Main Control Valve

Boom Down Relief 6894 (1000) ±689 kPa (100 psi) Main Control Valve

Front Stabilizer Extend (if equipped) 3447 (500) ±689 kPa (100 psi) Port Block on Front Stabilizer

Front Stabilizer Retract (if equipped) 12065 (1750) ±689 kPa (100 psi) Port Block on Front Stabilizer

System Stand-by Pressure 2585 (375) ±344 kPa (50 psi) Main Control Valve

Main/Aux Hoist Raise & Lower 29647 (4300) ±689 kPa (100 psi) Main Control Valve

System/Boom Up Relief 31026 (4550) ±689 kPa (100 psi) Main Control Valve

Swing Valve Relief (CW/CCW) 21373 (3100)

+689 kPa (200 psi)

-0 PSI

Swing Control Valve

Air Conditioning Relief Valve 25855 (3750) ±689 kPa (100 psi) Swing Control Valve

Front Stabilizer Extend (if equipped) 3447 (500) ±689 kPa (100 psi) Front Stabilizer

Front Stabilizer Retract (if equipped) 12065 (1750) ±689 kPa (100 psi) Front Stabilizer

Reference Only

Loading...

Loading...