A

B

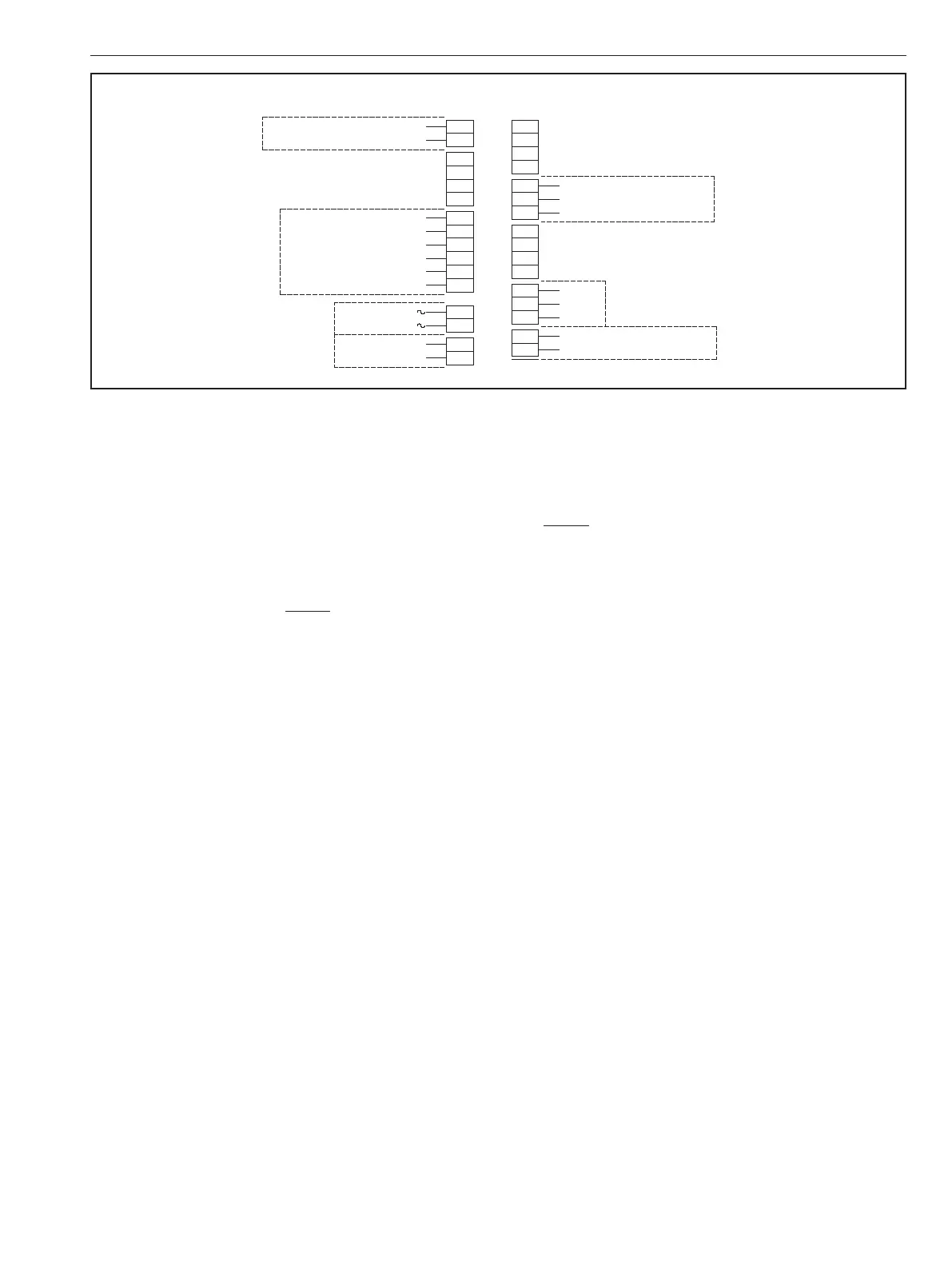

Hot / L1

115/230VAC

Neut. / L2

C

D

E

F

G

H

I

J

K

L

NO

NC

CW S witch 1 C OM

NO

NC

CCW Switch 2 C OM

mA / VDC+

Opt. External +24VDC F eedback

+

-

Wiper R esistive C ontrol

+

4-20mA or 0-10VDC Analog C ontrol

-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

mA / VDC-

17

18

19

20

24VAC

+

12/24VDC

-

Low Voltage Power

Auxiliary Switches

High V oltage P ower

Position C ontrol

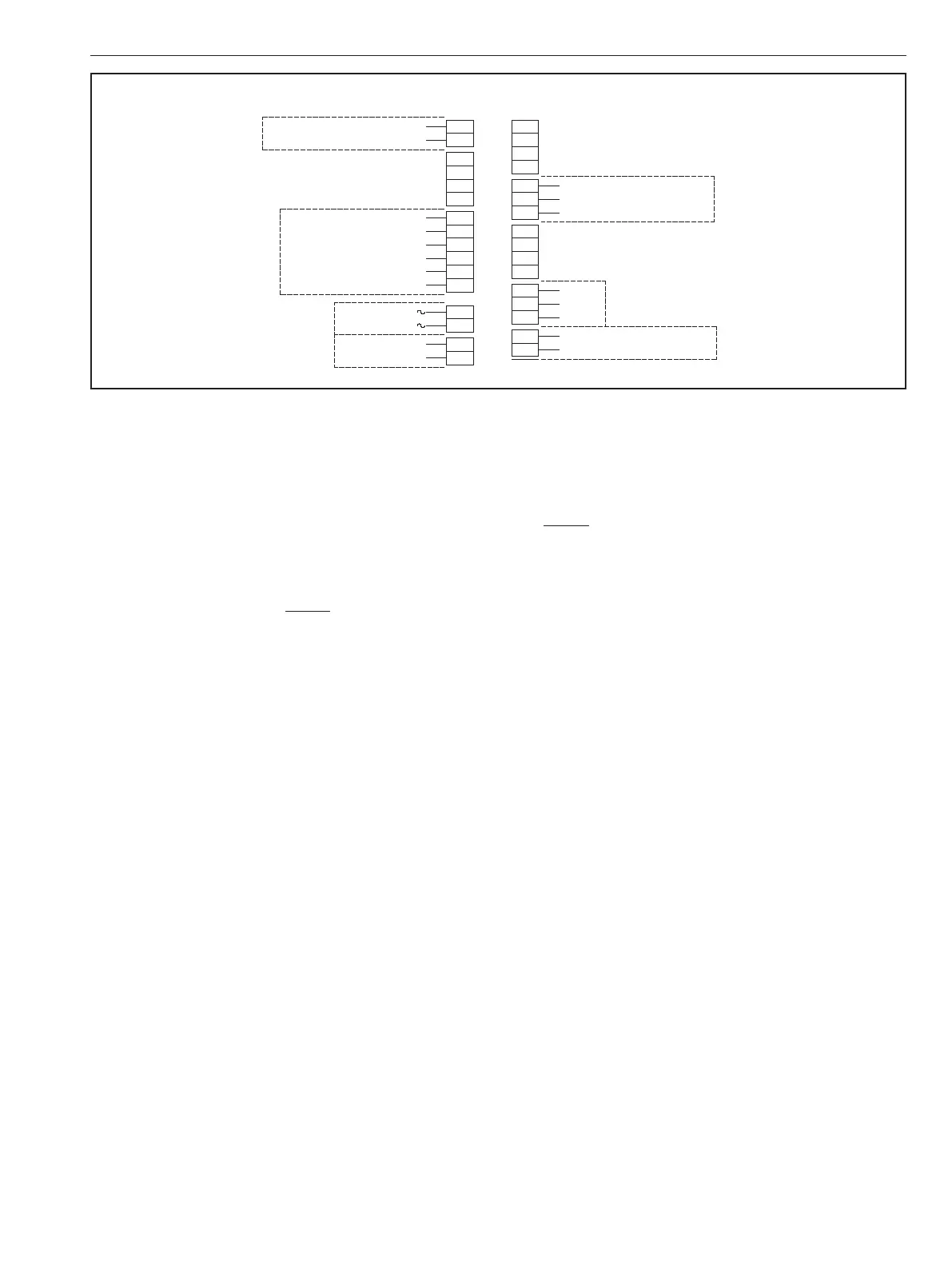

A

B

Hot / L1

115/230VAC

Neut. / L2

C

D

E

F

Hot / L1 CW

Hot / L1 MID

Hot / L1 CCW

Neut. / L2 C OM

G

H

I

J

K

L

NO

NC

CW S witch 1 C OM

NO

NC

CCW Switch 2 C OM

mA / VDC+

Opt. External +24VDC F eedback

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

mA / VDC-

17

18

19

20

24VAC

+

12/24VDC

-

Low Voltage Power

Auxiliary Switches

P os. / Hot C W

P os. / Hot MID

P os. / Hot CCW

115/230VAC

High V oltage P ower

On/O Control

High V oltage

On / O Control

Low Volta ge

On / O C ontrol

12/24VDC

or 24VAC

Neg. / Com. C OM

Positioning Control Wiring

Figure 12

7.3 Set Up and Calibration

7.3.1 Initial Set Up

1. Remove actuator cover. Remove the override shaft

from the actuator cover bushing; if the actuator is

equipped with a handwheel, remove the handwheel

before removing the top piece of the “two-piece” shaft

from the cover bushing. NOTE: Use caution to prevent

damage to machined flange surface of cover casting;

see cover replacement for additional information.

2. Select LIMIT type “Smart” by sliding the [Smart/Cam]

switch up to select Smart. Selecting Smart will enable

other features on the board such as Position Feedback.

3. Select Control Method “Analog” or “Resistive” by

turning the selection potentiometer with a small flat

blade screwdriver.

7.3.2 Potentiometer Calibration

Field installation of the Universal Control Board option

or replacement of the position tracking potentiometer

requires calibration of the position tracking potentiometer

prior to setting positions and values for ZERO, MID and SPAN.

Universal Control Board options installed at the factory are

fully calibrated at the factory and should not require further

calibration. To confirm proper potentiometer calibration:

1. Turn the Mode Selector Dial to [CAL] and press [ENTER]

for 2 seconds.

2. Using the CW pushbutton, drive the actuator to the

full clockwise position. - If the [CAL] LED is flashing,

potentiometer calibration is required; proceed to step

3 below. - If the [CAL] LED remains on, calibration is

not required; proceed to Setting ZERO, MID and SPAN

Positions section below.

3. Loosen the set screw in the gear with a 1/16” hex

wrench.

4. Rotate the gear until the LED remains on constantly;

hold the gear in place and tighten the set screw. Ensure

that the LED remains on after the set screw is tightened.

NOTE: The LED assists the user in locating the proper

calibration window; it will flash faster as you approach

the calibration window and slower as you move away

from it.

5. Press the [ENTER] button to save the potentiometer

setting.

7.3.3 Setting ZERO, MID, and SPAN Positions

Once (feedback potentiometer) calibration has been

confirmed, set the desired “end of travel” positions. Make

certain that the limit switch cams are set to operate the

switches beyond the desired range for the ZERO and SPAN

positions. ZERO and SPAN may be set at any position

between 0° and 94° of travel (0° and 184° with “U4”, “UL4” or

“UL5” option; or 0° and 274° with “U6”, “UL6” or “UL7” option).

Set ZERO (typically CW):

1. Turn the Mode Selector Dial to [ZERO] and press

[ENTER] for 2 seconds. The [ZERO] LED will begin to

flash.

2. Drive the actuator to desired clockwise position using

the CW or CCW push button. If the “STALL” LED

begins to flash; check to see if the limit switch cam is

preventing actuator from reaching desired ZERO end-

of-travel (the “Switch Trip” LED will be illuminated).

If necessary back the cam off so that it will trip the

switch slightly beyond the desired end-of-travel and

the “Switch Trip” LED will go out.

3. Apply the desired Analog Signal that will correspond

with the Zero position (ie 4mA).

4. Press the [ENTER] button to save the ZERO setting.

IMO 6/18

IMO-I4900 EN 11

Loading...

Loading...