Set MID: (if applicable)

1. Turn the Mode Selector Dial to [MID] and press [ENTER]

for 2 seconds. The [MID] LED will begin to flash.

2. Drive the actuator to the desired MID or “THIRD”

position using the CW or CCW push button.

3. Press the [ENTER] button to save the MID setting.

Set SPAN (typically CCW):

1. Turn the Mode Selector Dial to [SPAN] and press

[ENTER] for 2 seconds. The [SPAN] LED will begin to

flash.

2. Drive the actuator to desired counterclockwise position

using the CW or CCW push button. If the “STALL” LED

begins to flash; check to see if the limit switch cam is

preventing actuator from reaching desired SPAN end-

of-travel (the “Switch Trip” LED will be illuminated).

If necessary, back the cam off so that it will trip the

switch slightly beyond the desired end-of-travel and

the “Switch Trip” LED will go out.

3. Apply the desired Analog Signal that will correspond

with the Span position (ie 20mA).

4. Press the [ENTER] button to save the SPAN setting.

7.3.4 Verify End-Of-Travel Settings:

1. Turn the Mode Selector Dial to [RUN].

2. Apply various control signals to verify operation.

3. Verify that the “Switch Trip” LED is not illuminated at

either the ZERO or SPAN positions (if it is, “back” the

respective end-of-travel cam “o” of the respective

limit switch).

4. Replace actuator cover.

7.3.5 Proper Actuator Cover Replacement

NOTE: For actuators including hazardous location certi-

cation. Prior to installing cover, inspect machined ange

surfaces for any damage, scratches, or dents. Damage,

scratches, or dents that will not t completely in a circle

having a diameter of 1/64” will void hazardous location certi-

cations. If such imperfections are present the damaged

enclosure part(s) must be replaced. Consult the factory for

replacement parts.

1. Remove the override shaft from the actuator cover

bushing; if the actuator is equipped with a handwheel,

remove the handwheel before removing the top piece

of the “two-piece” shaft from the cover bushing.

2. Install the override shaft on the square motor shaft; if

the actuator is equipped with a handwheel, install the

bottom piece of the “two-piece” shaft on the motor

shaft and then install the top piece of the shaft onto

the bottom piece of the shaft.

3. Align cover so that the override shaft will pass through

the override bushing and carefully push it down so

that the cover flange contacts the base flange.

4. Once the cover is properly seated, tighten the screws

to secure the cover; a cross pattern is recommended

for uniform distribution of load.

5. If the position indicator is not seated to the output/

cam shaft, turn until it drops into place in order to

ensure accurate visual position indication.

7.4 Deadband Adjustment

Dead Band is the window of control signal change which

the actuator will ignore. The sensitivity of the actuator to

respond to changes in the control signal is adjustable.

Minimum Dead Band (1%) allows the actuator to respond

to small control signal changes. Maximum Dead Band (3%)

allows the actuator to ignore small control signal changes

(such as noise on the control signal).

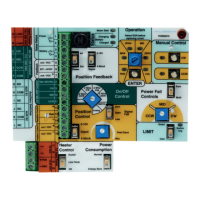

7.5 Signal Fail Options

In the event that the control signal to the actuator is lost

and external power is still applied, the Signal Fail position

selector switch on the Universal Control Board provides

options for the actuator to drive to the Zero (minimum

signal) position, the Span (maximum signal) position, or to

remain at its “Last” (current) position. NOTE: If you use a

0- 10VDC control signal, the actuator cannot differentiate

between a 0VDC signal and an actual loss of signal;

therefore, it will drive to the “Zero” position regardless of

the switch setting.

IMO 6/18

12 IMO-I4900 EN

Loading...

Loading...