Do you have a question about the Metso Valvcon ADC Series and is the answer not in the manual?

| Input Signal | 4-20 mA |

|---|---|

| Supply Voltage | 24 VDC |

| Type | Controller |

| Series | ADC |

| Communication Protocol | HART |

Provides essential information for the installation, operation, and maintenance of the Valvcon ADC-Series electric actuator.

Details the identification label attached to the actuator base casting, listing key specifications and certifications.

Highlights critical warnings regarding actuator performance and electrical limitations to prevent damage or injury.

Explains the ADC-Series actuators, their enclosure types, torque ranges, and optional battery back-up features.

Details the Universal Control Board, its capabilities, and its role in ADC-Series actuator operation.

Describes the interface of the Universal Control Board, including LED indicators for different operational modes.

Explains the function of the Operation Mode Selector Pot and its corresponding LED indicators.

Details the Control Mode Selector Pot for choosing between On/Off and Position Control modes.

Describes how limit cams and switches function as safety stops for electronic travel limits.

Explains the 'Smart Limit' feature for electronically setting precise end-of-travel positions for actuators.

Details the 'Cam Limit' type, using mechanical limit switches operated by cams for setting travel limits.

Describes the built-in heater/thermostat option for controlling operation in low-temperature or high-humidity environments.

Explains the actuator's torque limit feature and the location of the setting potentiometer.

Provides wiring instructions for connecting 115VAC or 230VAC main input power to the Universal Control Board.

Details the wiring requirements for connecting 24VAC main input power to the Universal Control Board.

Explains how to wire 12VDC or 24VDC main input power to the Universal Control Board.

Describes the three methods of On/Off control: 2 Wire CW, 2 Wire CCW, and 3 Wire Jogging/Latching.

Provides wiring diagrams and instructions for high and low voltage On/Off control signals.

Details the procedures for setting up and calibrating the actuator for On/Off control modes.

Step-by-step guide for initial setup, including cover removal and selecting limit types and control methods.

Instructions for calibrating the position tracking potentiometer for accurate end-of-travel settings.

Procedure for setting the desired ZERO, MID, and SPAN end-of-travel positions for the actuator.

Guidance on verifying the set end-of-travel positions and proper actuator cover replacement.

Instructions for correctly reinstalling the actuator cover, emphasizing care for hazardous location certifications.

Explains position control modes: 4-20mA Current Analog, 0-10VDC Voltage Analog, and Resistive Control.

Provides wiring details for analog and resistive position control signals to the Universal Control Board.

Covers setup and calibration for position control, including initial setup and potentiometer calibration.

Step-by-step process for initial setup of the actuator for position control applications.

Instructions for calibrating the position tracking potentiometer for position control settings.

Procedure to set ZERO, MID, and SPAN positions for position control, including signal application.

Guidance on verifying end-of-travel settings for position control and proper cover replacement.

Detailed steps for replacing the actuator cover, with emphasis on maintaining certifications.

Explains how to adjust the deadband to control actuator sensitivity to signal changes.

Details the options for actuator behavior upon loss of control signal, including Zero, Span, or Last position.

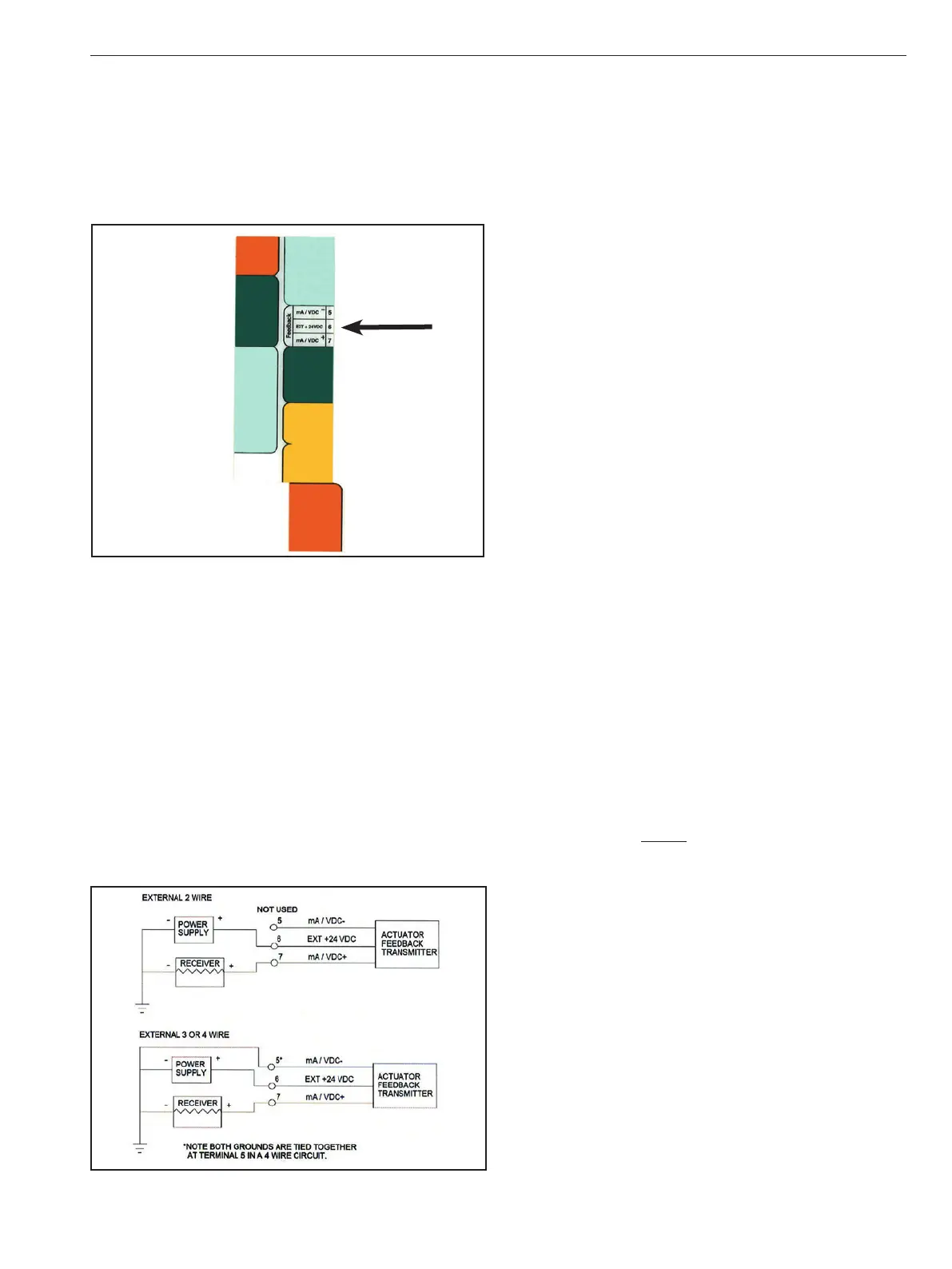

Describes how position feedback indicates actuator output position and its wiring for 4-20mA and 0-10VDC.

Covers status indicators including auxiliary switches, power status relay, and battery status relay.

Details the optional battery backup system, its charging, and maintenance requirements.

Explains configuration options for actuator behavior upon loss of external power (Fail position).

Describes how to wake the actuator from sleep mode and manually drive it using battery power.

Explains the 'Energy Save' mode feature that reduces power consumption by 'dozing' the unit.

Critical safety warnings for working inside the actuator cover with dangerous voltages present.

Specific safety warnings for units with an optional battery, emphasizing potential actuator movement.

Steps for verifying replacement board kits, inspecting parts for shipping damage, and collecting tools.

Detailed instructions for removing the actuator control board, including cover and overlay removal.

Provides step-by-step instructions for installing the replacement actuator control board, connecting cables and securing it.

Details enclosure specifications, NEMA ratings, and certifications like CSA and ATEX for ADC-Series actuators.

Specifies the operating temperature range for ADC-Series actuators and recommendations for ambient temperature management.

Provides guidelines for mounting the actuator in various positions, emphasizing secure attachment and alignment.

Instructions on how to use the manual override feature, including precautions to prevent actuator damage.

Information that the actuators' power train components are permanently lubricated and require no additional lubrication.

Highlights common issues arising from improper installation, wiring, setup, coupling, alignment, and mounting.

Outlines the standard 2-year warranty for V-Series actuators and procedures for warranty claims.

Provides contact information and procedures for obtaining repair services and ordering spare parts.

Details control board specifications including input impedance, signal types, stall protection, and dead band.

Provides detailed dimensional drawings and specifications for ADC-Series actuator enclosures.