5-88

Maintenance and inspection procedures

5 Maintenance and Inspection

3) Make marks on the timing belt <2> and timing pulleys <4> and <5> with a felt-tip pen as shown in Fig. 5-7 so

that the engagement of the timing belt <2> and timing pulleys <4> and <5> does not deviate.

4) Lightly loosen the two motor plate installation screws <1>. (Do not loosen too much.)

5) Loosen the nut fixing tension adjustment screw <3>. Loosen the tension adjustment screw <3>, and remove

the old belt.

6) Copy the marks onto the new timing belt. Make sure that both belts are tense when making the marks.

7) Align the new timing belt with the marks on the timing pulleys <4> and <5>, and install.

8) Refer to " ■ Adjusting the J3 axis timing belt" and "(8)Timing belt tension" to adjust the tension.

9) The position could deviate after the belt is replaced. Confirm that the position has not deviated. If deviated,

refer to Page 104, "5.6 Resetting the origin", and reset the origin position.

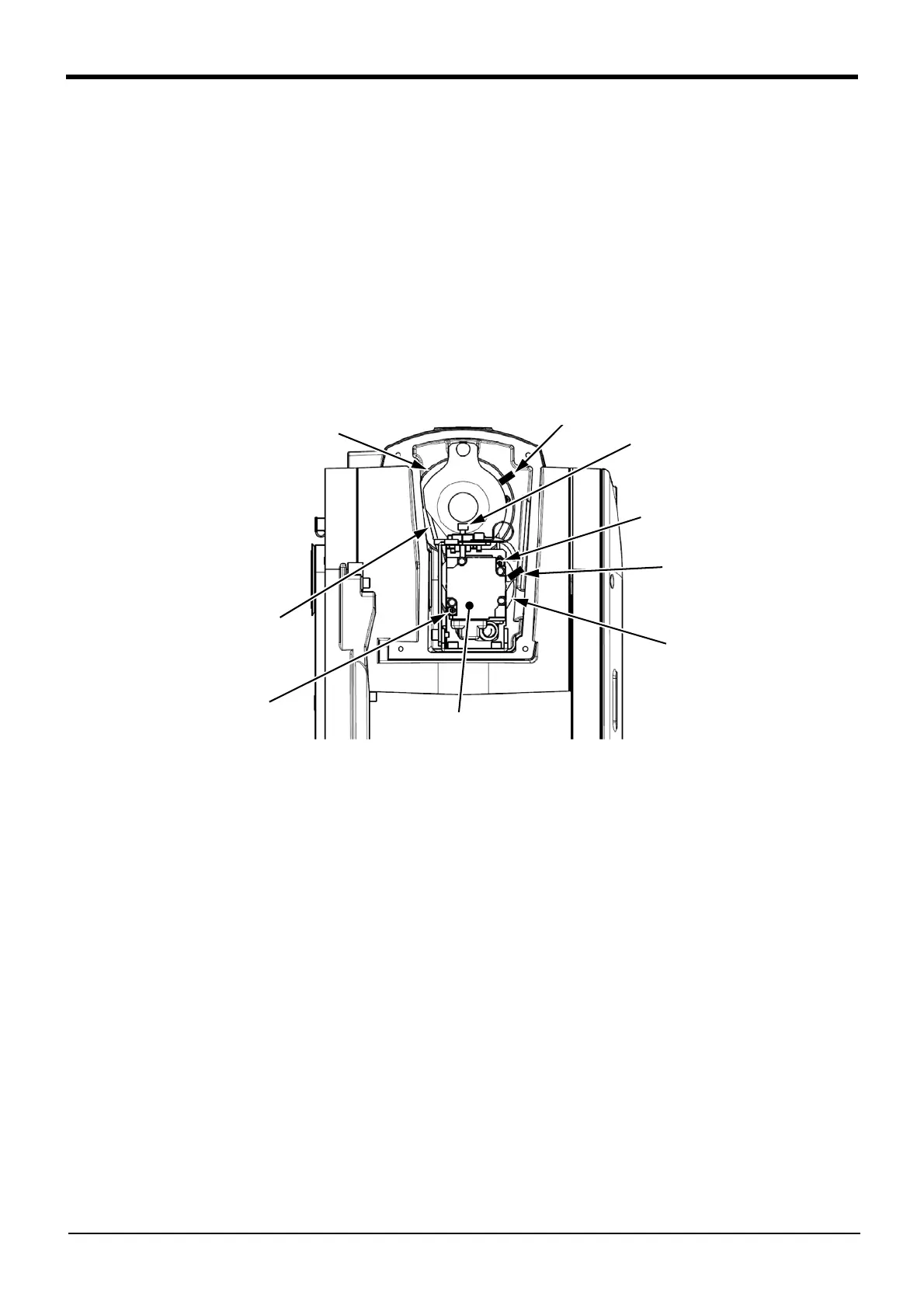

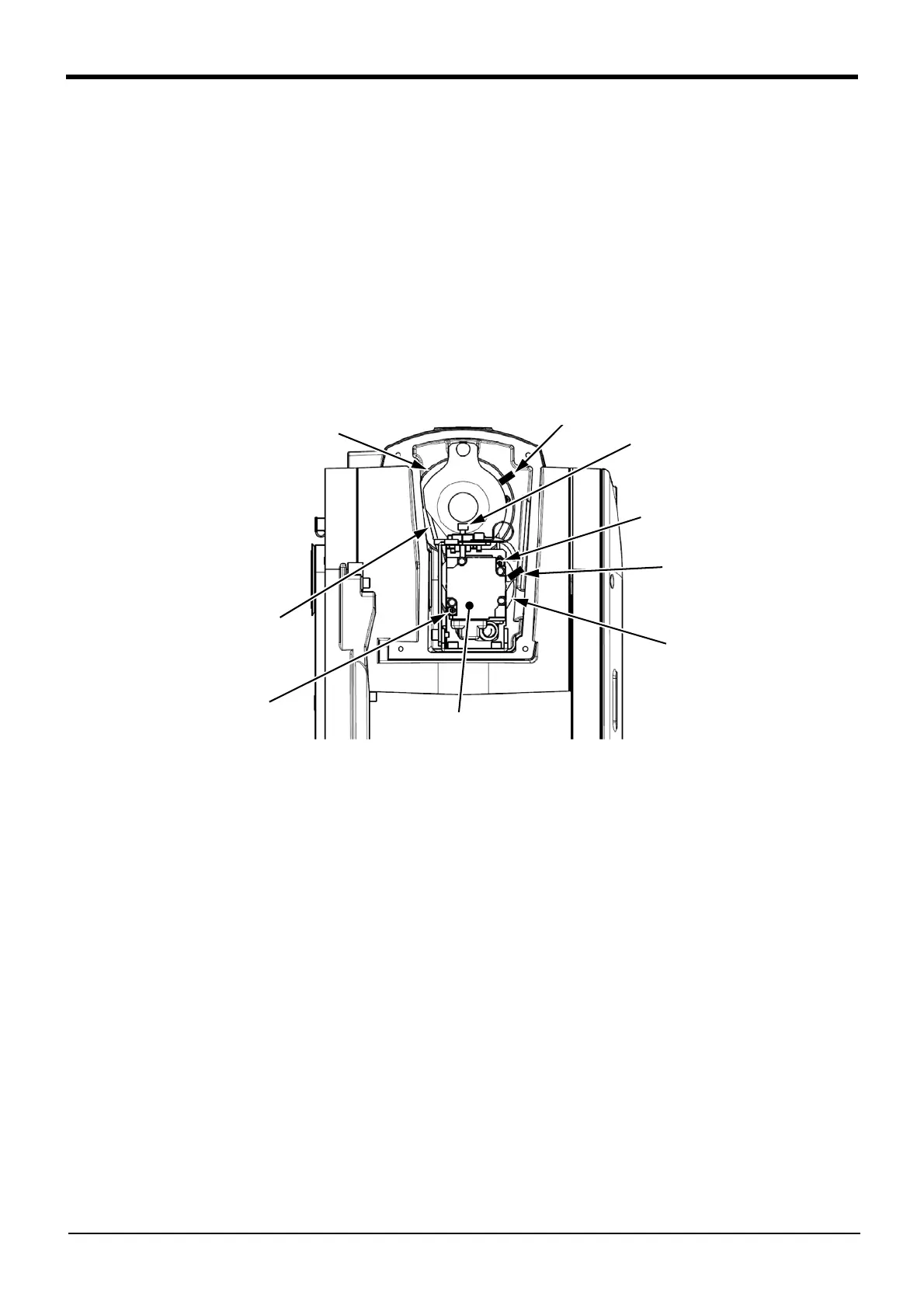

(4) Inspection, maintenance and replacement of J4-axis timing belt

The reference figure at inspection, adjustment, and replacement of the timing belt is shown in Fig. 5-8.

Fig.5-8 : Inspection, maintenance and replacement of J4 axis timing belt (RV-4F/7F series)

■ Inspecting the J4 axis timing belt

1) Confirm that the robot controller power is OFF.

2) Refer to Page 82, "5.3.2 Installing/removing the cover", and remove the elbow cover.

3) Visually confirm that the symptoms indicated in "(1)Timing belt replacement period" have not occurred with

the timing belt.

4) Confirm that the belt tension is adjusted to slacken as shown in "Fig.5-14 : Belt tension".

■ Adjusting the J4 axis timing belt

1) Carry out steps 1) and 2) indicated in " ■ Inspecting the J4 axis timing belt" above.

2) Lightly loosen the two

motor plate fixing screws <1>. (Do not loosen too much.)

3) The nut which is fixing tension adjustment screw <3> is loosened, turn the tension adjustment screw <3>, and

adjust the tension of timing belt <2>.

When the screw is turned to the right, the belt will be stretched, and when turned to the left, will loosen.

Adjust the belt tension slack to within the range as shown in "Fig.5-14 : Belt tension".

If the belt is loosened too much when adjusting the tension causing it to come off the timing pulleys <4> and

<5>, or if the belt and pulley teeth engagement is deviated, the machine system's origin will deviate.

4) After adjustment fastens the fixing nut of tension adjustment screw <3>, and certainly fixes tension

adjustment screw <3>. Moreover, also fasten

motor plate fixing screw <1> certainly. (two pc.) Improper tightening

can cause the belt to loosen with vibration.

■ Replacing the J4 axis timing belt

Carries out the replacement of the timing belt of the J4 axis by our service provider. Please contact our service

provider after confirming the robot arm and the serial number of the controller.

<1>Motor plate fixing screw

<3>Tension adjustment screw

With the fixing nut

<5> Timing pulley

(joint side)

<4> Timing pulley

(motor side)

<1>Motor plate fixing screw

<2> Timing belt

Mark

Mark

J4 axis motor

Loading...

Loading...