FUEL SYSTEM

8-6

2.1.2 Inspecting and adjusting fuel injection

valve opening pressure

&$87,21

Never touch the injection nozzle tip during nozzle

injection test.

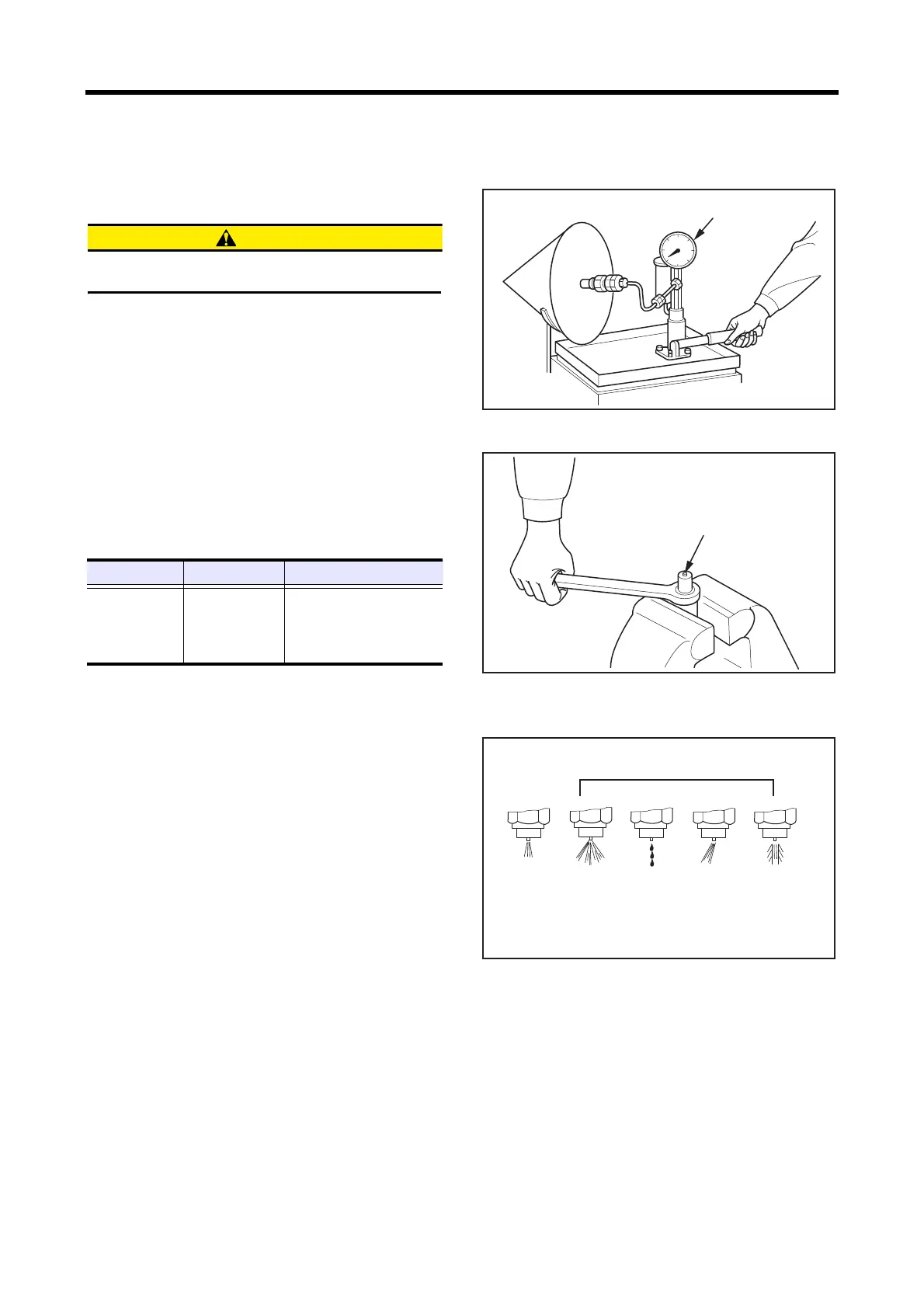

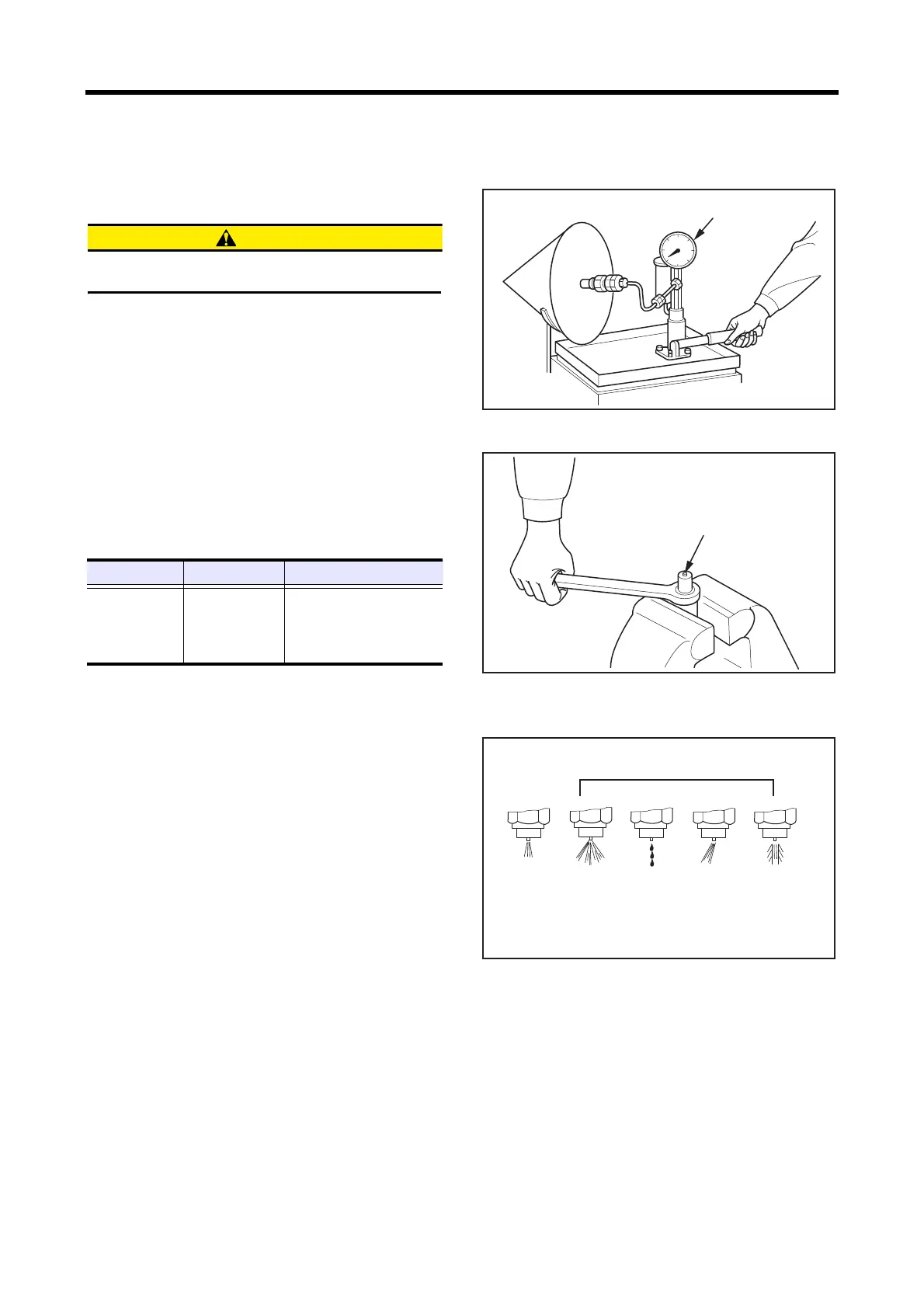

(1) Mount the nozzle on the nozzle tester.

(2) Push down the handle at a speed of once a second and

read the pressure when injection starts. Make

adjustment if it is outside the standard.

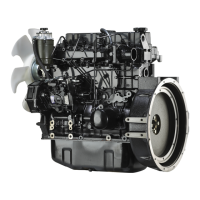

(3) To adjust the injection start pressure, remove the set

screw on the nozzle holder, loosen the cap nut and turn

the adjusting screw with a driver.

(4) After adjustment, tighten the cap nut and set screw with

the specified torque.

(5) After tightening the set screw, check if the injection

start pressure is within the standard again.

Inspecting fuel injection valve opening pressure

Replacing fuel injection nozzle tips

2.1.3 Inspecting fuel spray pattern of fuel injec-

tion nozzle

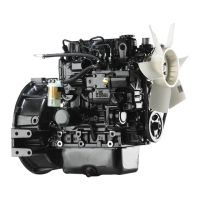

(1) When adjusting the nozzle opening pressure using the

nozzle tester, check for nozzle hole condition, and fuel

spray pattern.

(2) Checking points of fuel spray are as follows:

· Fuel is injected from all spray holes simultaneously.

· Fuel is injected conically at the specified spray angle.

· Fuel is injected in a spray of fine droplets.

· Fuel is injected without after-dribbling.

(3) If spray condition is faulty, clean or replace the nozzle

tip.

Inspecting fuel spray pattern from fuel injection nozzle

Item Nominal Standard

Valve opening

pressure

13.73 MPa

{140 kgf/cm²}

[1991 psi]

14.22 to 15.00 MPa

{145 to 153 kgf/cm²}

[2062 to 2176 psi]

(New parts value)

Nozzle tester

Nozzle tip end

Good

Large

spray

angle

After

dribble

Branched

spray

Deflected

spray

Defective spray pattern

Loading...

Loading...