REASSEMBLY OF BASIC ENGINE

7-8

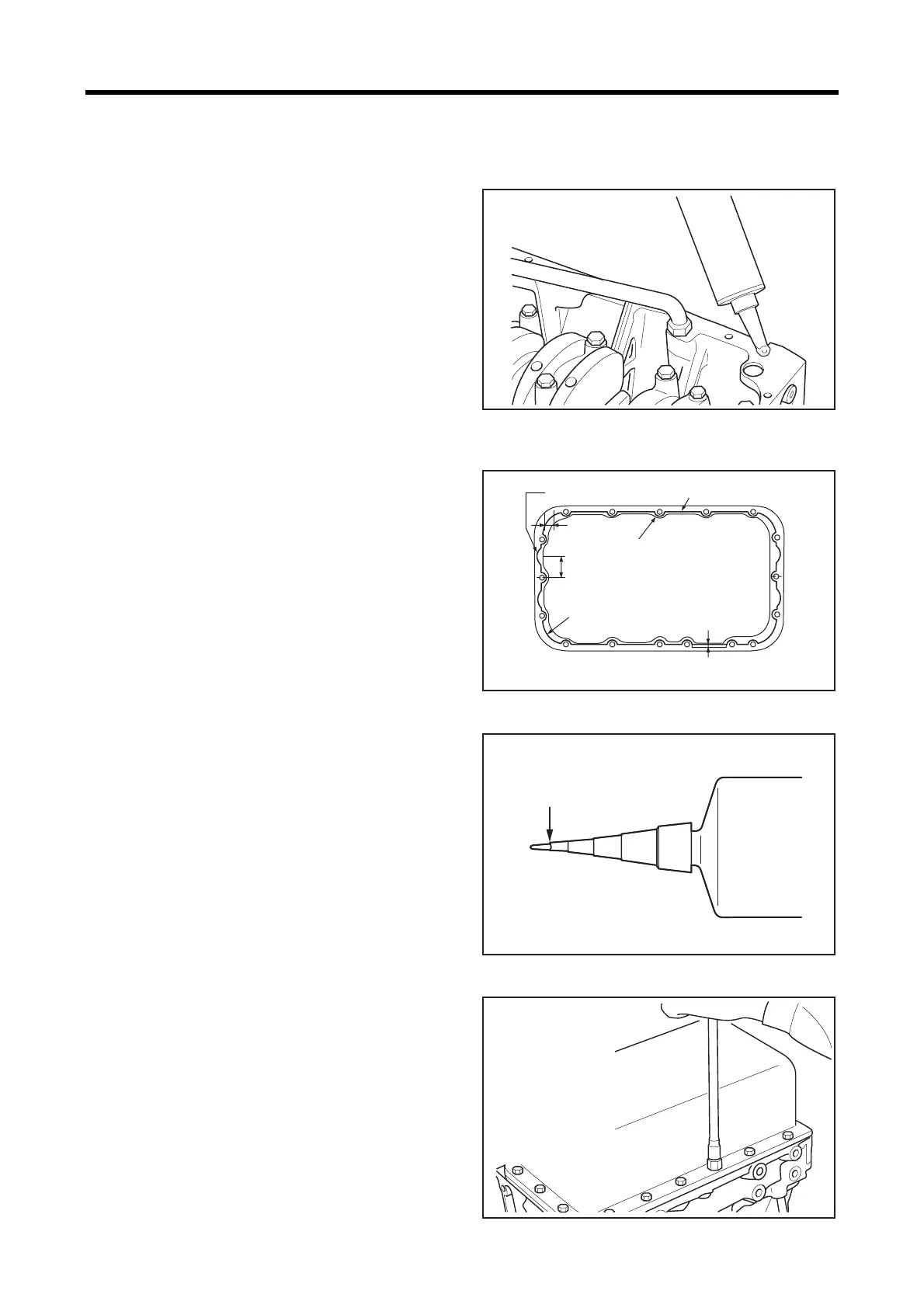

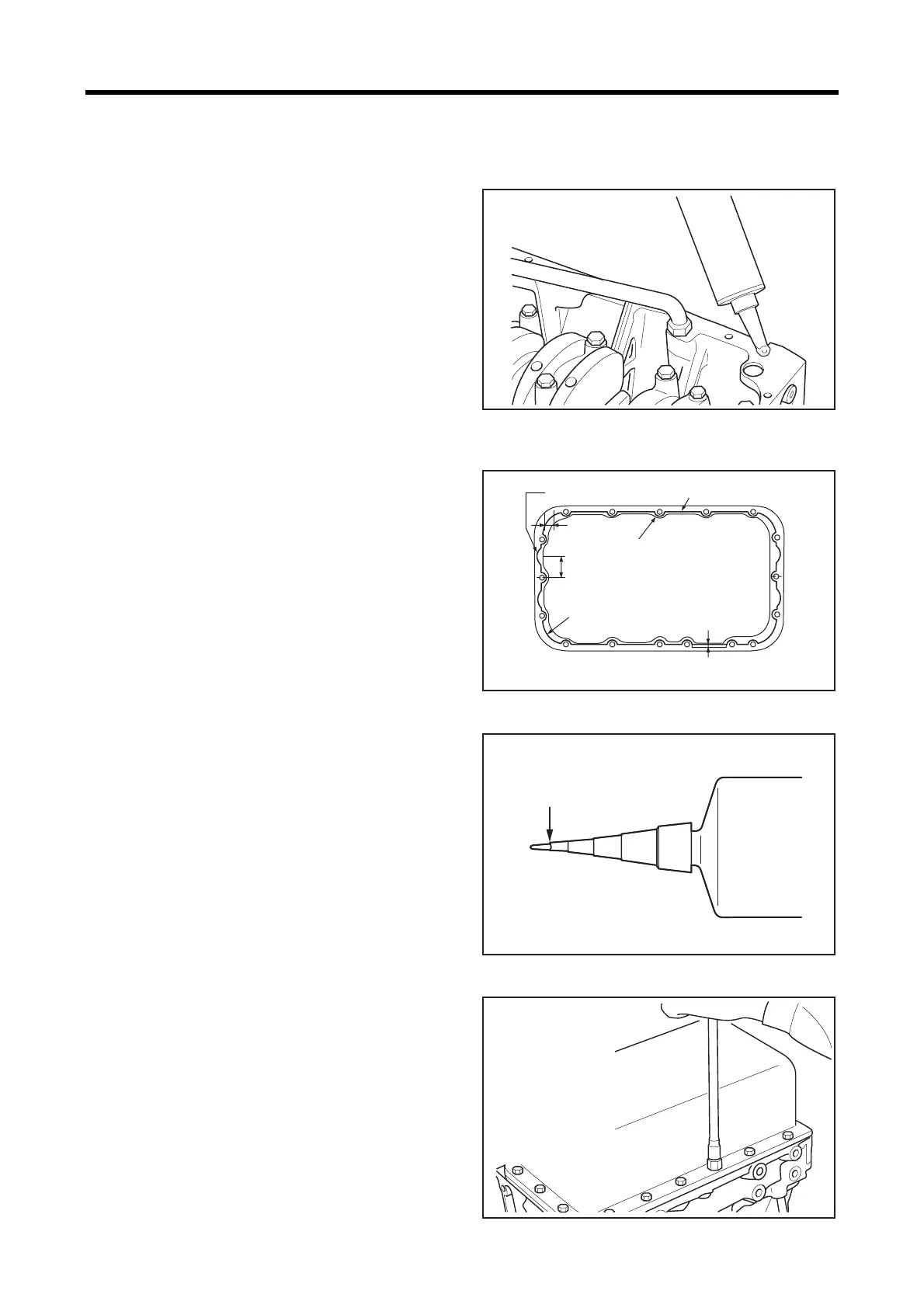

1.12 Installing oil pan

(1)

Clean the cylinder block and oil pan mating surfaces.

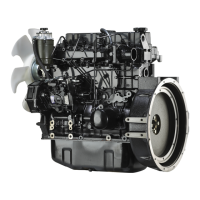

(2) Apply sealant (ThreeBond 1207C) to the all

circumference of cylinder block mating surface.

Note: (a) Squeeze the sealant in a bead of 4mm, and apply

to the specified part shown in the illustration.

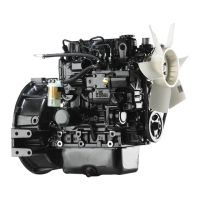

(b) Cutting the top of the sealant tube at the point

shown in the illustration will provide a 4mm

bead.

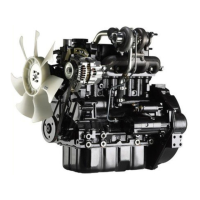

(3) Install the oil pan.

(4) Tighten the oil pan mounting bolts diagonally in several

steps, and finally to the specified torque.

Applying sealant to oil pan mounting face of cylinder

block

Sealant application pattern

Cutting end of sealant tube

Installing oil pan

R17 (4 front and rear

locations in total)

Apply sealant as lined

9.5 [0.37]

R7 from hole center

(same for all 17 holes)

36

[1.42]

R40 corresponding to

hole centers

(same for all 4 corners)

5 [0.20]

Apply oil pan liquid gasket here (top face)

FrontRear

Unit: mm [in.]

Cut here

Tightening torque

Press oil pan

9.80 to 12.7 N·m

{1.0 to 1.3 kgf·m}

[7.2 to 9.4 lbf·ft]

Cast oil pan

24.5 to 30.4 N·m

{2.5 to 3.1 kgf·m}

[18.1 to 22.4 lbf·ft]

Loading...

Loading...