INSPECTION AND REPAIR OF BASIC ENGINE

6-4

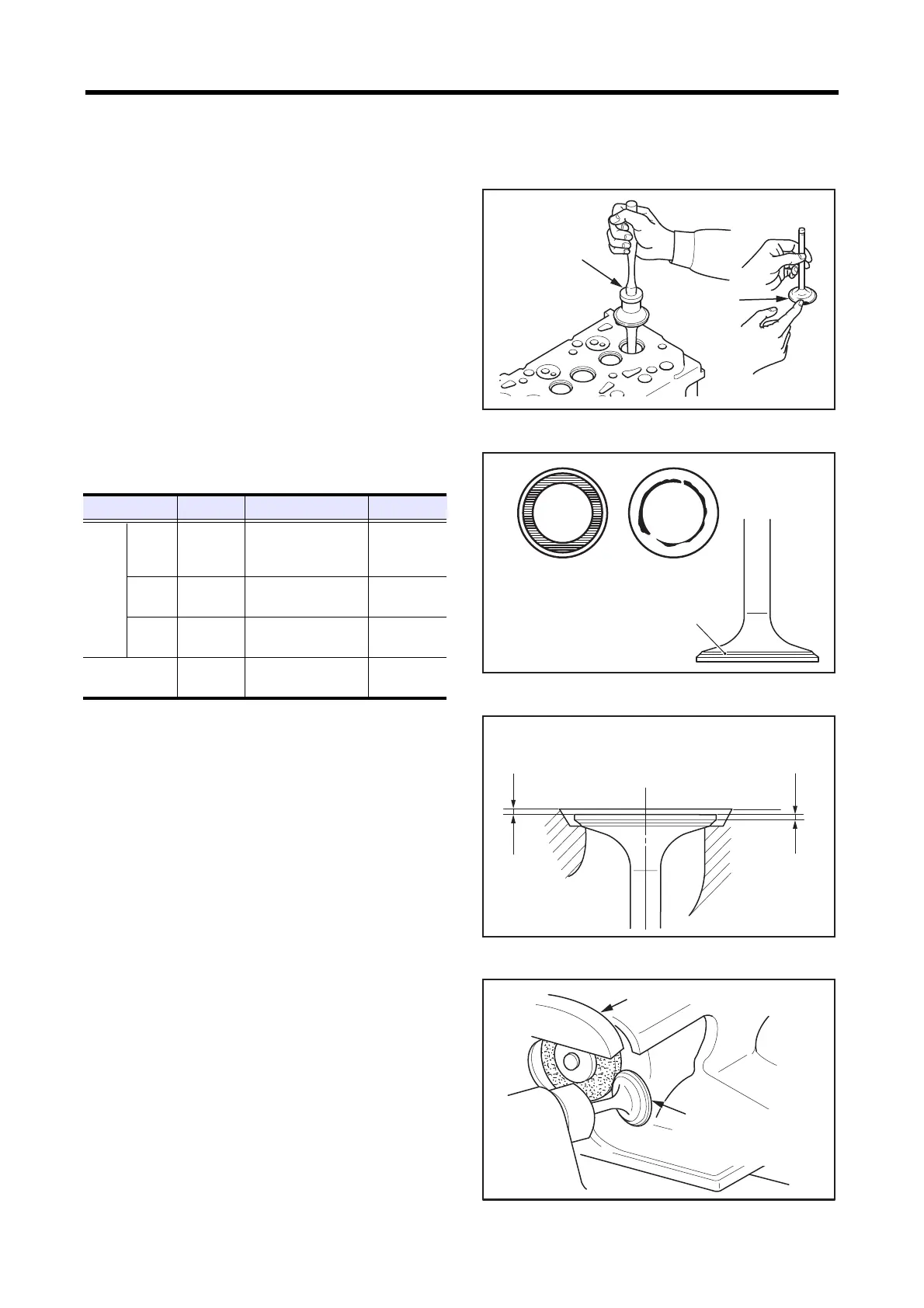

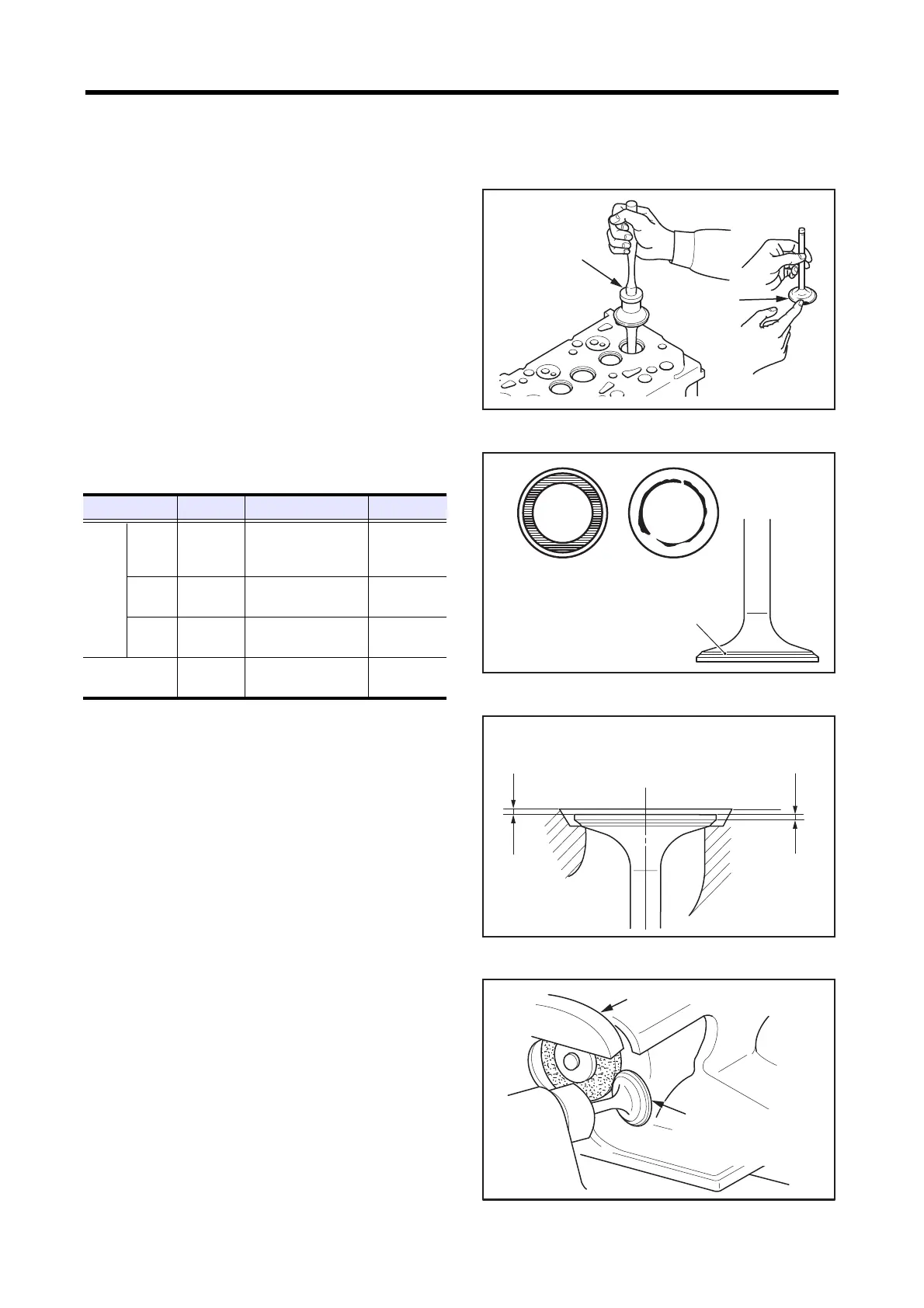

1.7 Inspecting valve face

Apply a thin coat of Shinmyoutan or equivalent lead-free

coloring paste on the valve face, and strike the valve face

against the valve seat using a valve lapper to check for

contact condition. If the contact is not even, or any defects

are found, or if the limit is exceeded, reface or replace the

valve.

Note: (a) Inspect the valve face after the valve guide is

repaired or replaced.

(b) Do not rotate the valve when pressing the valve

face coated with Shinmyoutan or equivalent lead-

free dye against the valve seat.

(c) Always lap the valve and valve seat after the

valve has been refaced or replaced.

Refacing valve face

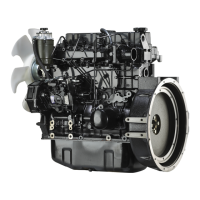

Contact between valve seat and valve

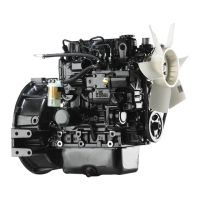

Valve sinkage

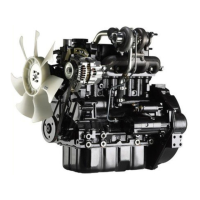

1.8 Refacing valve face

If the valve face is significantly worn out, reface the valve

face using a valve refacer.

Note: (a) Grind the valve face using the valve refacer at the

specified angle.

(b) Secure the valve margin width equal to or greater

than the limit. If the dimensions after refacing

does not meet the specified values, replace the

valve with a new one.

Refacing valve face

Item Nominal Standard Limit

Va lv e

seat

Va lv e

seat

angle

45° - -

Va lv e

sinkage

0 mm

[0.00 in.]

0.25 to 0.75 mm

[0.0098 to 0.0295 in.]

1.50 mm

[0.0591 in.]

Seat

width

1.6 mm

[0.063 in.]

1.30 to 1.80 mm

[0.0512 to 0.0709 in.]

2.50 mm

[0.0984 in.]

Valve margin

1.5 mm

[0.059 in.]

1.35 to 1.65 mm

[0.0531 to 0.0650 in.]

0.50 mm

[0.0197 in.]

Valve lapper

Shinmeitan

Good

Bad

Contact

(must be at face center)

Valve head

sinkage

Valve head

margin

Set the valve face

angle at the specified

angle.

Valve refacer

Loading...

Loading...