INSPECTION AND REPAIR OF BASIC ENGINE

6-11

4. Inspecting and repairing cylinder block, crankshaft and piston

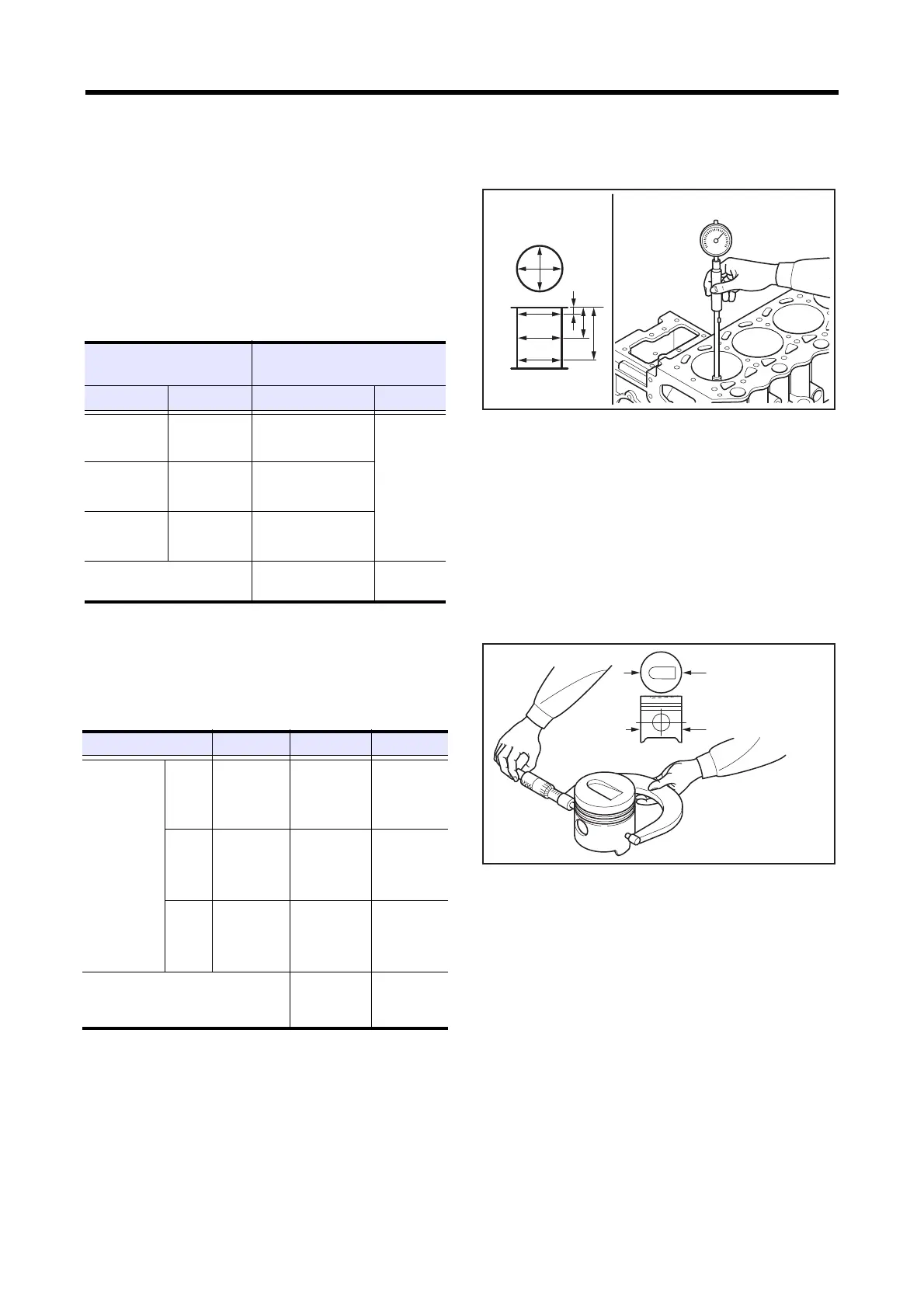

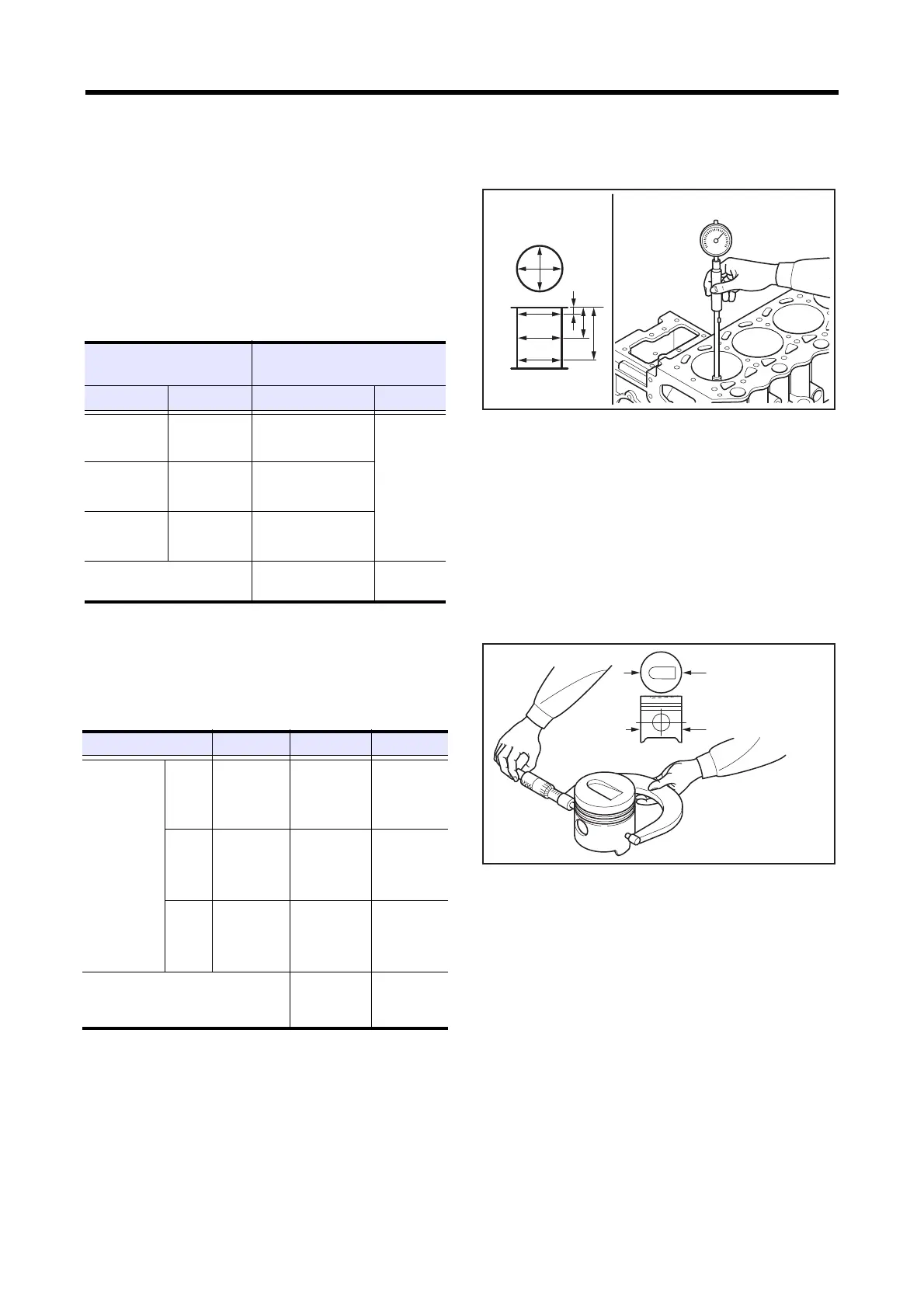

4.1 Measuring cylinder inside diameter

Use a cylinder gauge to measure the inside diameter and

cylindericity of the cylinder at three locations in the A and B

directions as shown in the illustration.

If any one of the cylinders exceeds the repair limit, bore all

the cylinders and replace the pistons and piston rings with

oversize ones.

Measuring cylinder inside diameter

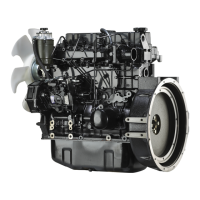

4.2 Measuring piston outside diameter

Using a micrometer, measure the piston outside diameter at

the skirt perpendicular to the piston pins as shown in the

illustration.

Measuring piston outside diameter

Piston and piston ring

size

Cylinder inside diameter

Size Size mark Standard Limit

S.T.D STD

ø 78

+0.030

+0.060

mm

[3.0709

+0.012

+0.024

in.]

Standard

+0.2 mm

[0.008 in.]

0.25 mm O.S

[0.0098 in.]

25

ø 78.25

+0.030

+0.060

mm

[3.0807

+0.012

+0.024

in.]

0.50 mm O.S

[0.0197 in.]

50

ø 78.50

+0.030

+0.060

mm

[3.0905

+0.012

+0.024

in.]

Cylindericity of cylinder

± 0.01 mm

[0.0004 in.] or less

-

A

B

Measuring

points

Measuring

directions

Item Nominal Standard Limit

Piston outside

diameter

STD

78.00 mm

[3.0709 in.]

77.93 to

77.95 mm

[3.0681 to

3.0689 in.]

77.80 mm

[3.0630 in.]

0.25

OS

78.25 mm

[3.0807 in.]

78.18 to

78.20 mm

[3.0779 to

3.0787 in.]

78.05 mm

[3.0728 in.]

0.50

OS

78.50 mm

[3.0905 in.]

78.43 to

78.45 mm

[3.0878 to

3.0886 in.]

78.30 mm

[3.0827 in.]

Weight difference per piston

±5g

[0.18 oz.]

or less

-

Measuring point

Direction at right

angles to piston pin

Loading...

Loading...