TRANSMISSION SYSTEM

(1) Before starting

the

reassembly work, be

sure

that

all transmission parts are perfectly

clean, check

to

be sure

that

there

is

no

missing parts, and,

when

building

up

sub-

assemblies, refer

to

the

specifications and

assembly standards

to

make

sure

that

each

sub-assembly

is

properly

built

up

with

respect

to

gaps, running clearances, plays,

backlashes, etc.

(2)

Oil

or

grease sliding surfaces,

as

necessary,

at

the

time

of

installing moving parts.

Similarly, grease

"0"

rings, oil seals and

the

like

just

before fitting

them.

(3)

It

is

advisable

but

not

mandatory

that

"0"

rings, gaskets, packings, oil seals,

tab

washers and

the

like be regarded

as

ex-

pendable items and be replaced by new

ones

upon

their

removal in disassembly.

(4)

Wrap through-bolts

with

sealing tape

just

before using

them

in reassembly.

(5)

Have sealant on

hand

and use

it

on the

mating faces

of

cases and covers.

(6)

Build up the transmission in

the

following

sequence:

5-12

(a) Differential gear reassembly

(b)

Determination

of

shim thickness

on

the

basis

of

countershaft

cone

center

meas-

surement

(c) PTO drive

shaft

(rear-side) reassembly

(d) PTO drive shaft (front-side) reassem bly

(e) PTO shaft reassembly

(f)

Reverse

shaft

reassembly

(g)

Countershaft

reassembly

(h) PTO gear

tooth

alignment

and

adjust-

ment

(i) Mid-PTO shaft reassembly

U) Main shaft installation

(k) Select shaft reassembly

(1)

Differential gear installation

(m) Final case reassembly

(n) Final case installation.

(0)

Speed change

shifter

reassembly

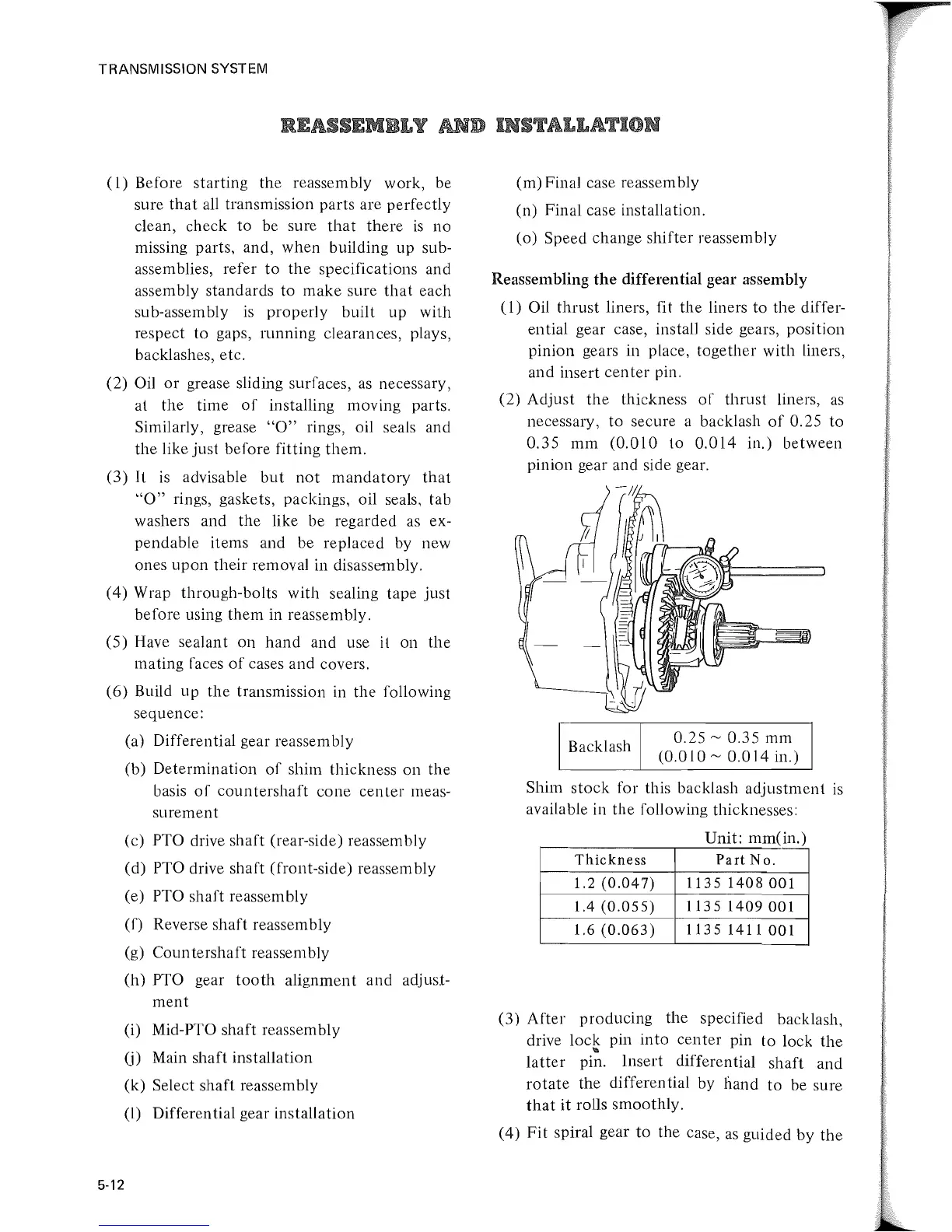

Reassembling

the

differential gear assembly

(1)

Oil

thrust

liners, fit

the

liners

to

the differ-

en tial gear case, install side gears, position

pinion gears in place,

together

with

liners,

and insert

center

pin.

(2)

Adjust

the

thickness

of

thrust

liners,

as

necessary,

to

secure a backlash

of

0.25

to

0.35

mm

(0.010

to

0.014

in.)

between

pinion gear and side gear.

Backlash

0.25

~

0.35 mm

(0.010

~

0.014

in.)

Shim

stock

for this backlash

adjustment

is

available in

the

following thicknesses:

Unit·

mm(in)

Thickness

Part

No.

1.2

(0.047)

1135

1408001

1.4(0.055)

1135

1409

001

1.6

(0.063)

1135

1411

001

(3)

After

producing

the

specified backlash

,

drive

lock

pin

into

center

pin

to

lock the

...

latter

pin. Insert differential

shaft

and

rotate

the differential by

hand

to

be sure

that

it

rolls smoothly.

(4)

Fit

spiral gear

to

the

case,

as

guided by

the

l\

SI

Loading...

Loading...