TRANSMISSION SYSTEM

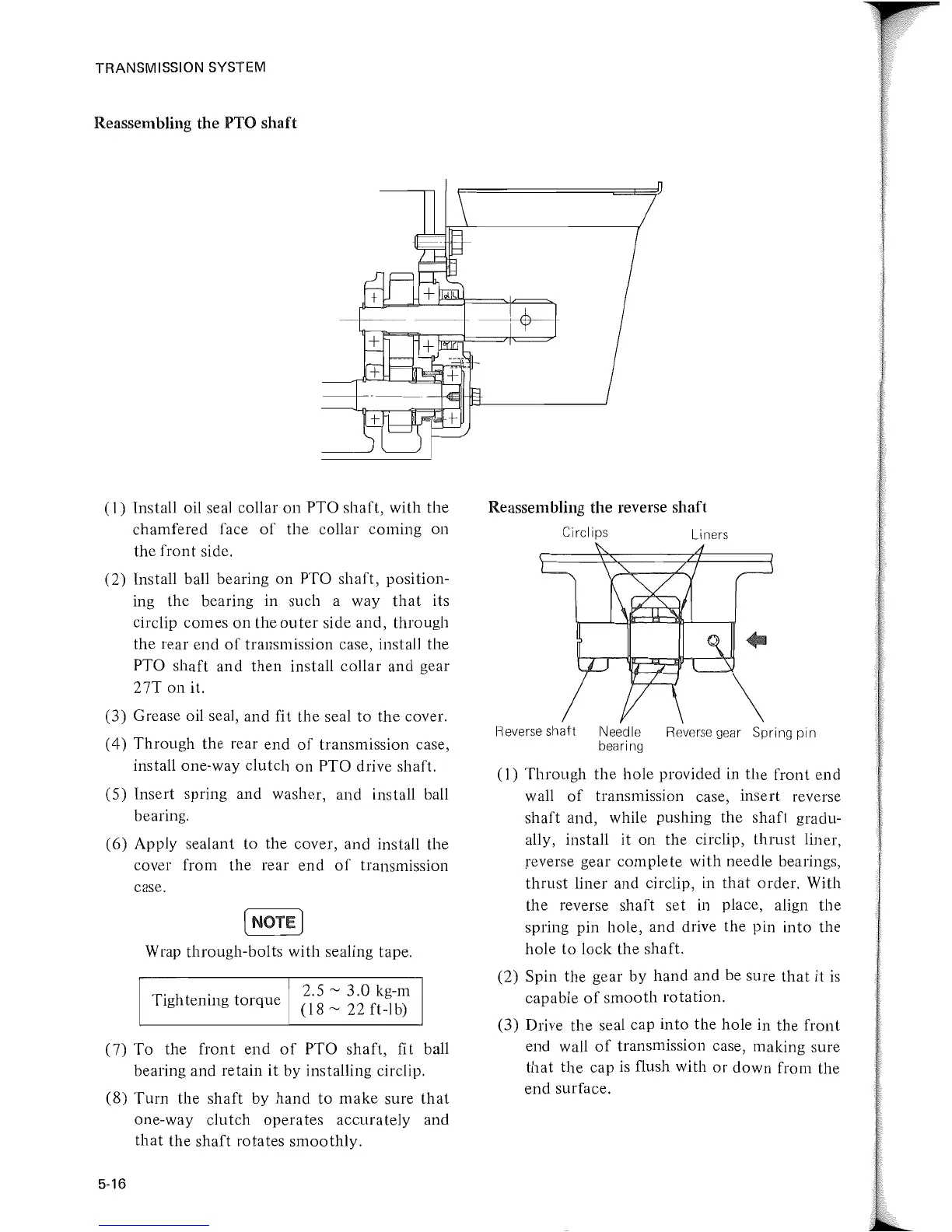

Reassembling

the

PTO

shaft

(l)

Install oil seal collar

on

PTO

shaft,

with the

chamfered face

of

the

collar coming

on

the

front

side.

(2) Install ball bearing

on

PTO

shaft,

position-

ing the bearing in

such

a way

that

its

circlip comes

on

the

outer

side and,

through

the rear end

of

transmission case, insta1l the

PTO

shaft

and

then

install collar and gear

27T

on

it.

(3)

Grease oil seal, and fit the seal

to

the

cover.

(4)

Through

the rear end

of

transmission case,

install one-way

clutch

on

PTO drive shaft.

(5) Insert spring and washer, and install ball

bearing.

(6)

Apply sealant

to

the cover,

and

install

the

cover from the rear

end

of

transmission

case.

[NOTE]

Wrap through-bolts with sealing tape.

Tightening

torque

2.5

~

3.0

kg-m

(18

~

22 ft-lb)

(7)

To

the

front

end

of

PTO

shaft,

fit

ba1l

bearing and retain

it

by

installing circlip.

(8)

Turn

the

shaft

by

hand

to

make

sure

that

one-way

clutch

operates accurately and

that

the

shaft

rotates

smoothly.

5-16

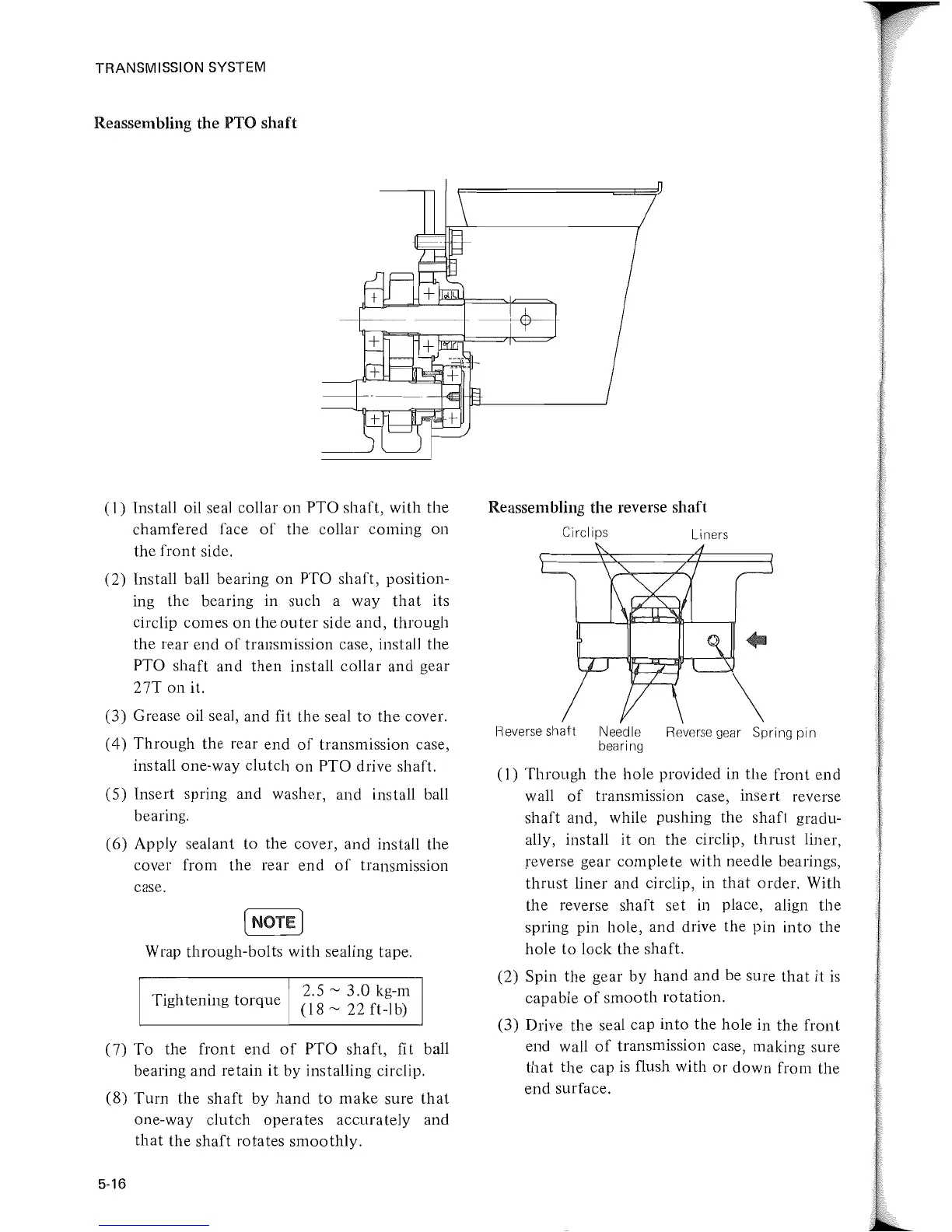

Reassembling

the

reverse

shaft

Circlips

Liners

Reverse

shaft

Needle Reverse gear

Spring

pin

beari

ng

(l)

Through

the

hole provided in the

front

end

wall

of

transmission case, insert reverse

shaft

and, while pushing

the

shaft

gradu-

ally, install

it

on

the circlip,

thrust

liner,

reverse gear

complete

with

needle bearings,

thrust

liner and circlip, in

that

order. With

the

reverse shaft set in place, align

the

spring pin hole, and drive the pin

into

the

hole

to

lock

the

shaft.

(2) Spin the gear

by

hand

and be sure

that

it

is

capable

of

smooth

rotation.

(3) Drive the seal cap

into

the hole in the

front

end wall

of

transmission case, making sure

that

the

cap

is

flush with

or

down

from the

end

surface.

Loading...

Loading...