the delivery valve and spring in place

and with the injection pipes properly

installed: this

is

an alternate checking

method.

In

this case, disconnect No. I

pipe from its nozzle holder. Using a

socket wrench at the crank pulley nut,

gradually

turn

over engine crankshaft to

let No. I pumping element force fuel

out

of

the pipe. The

moment

the

fuel starts

swelling

out

of

the pipe

is

the

start

of

injection. This will occur approx. I deg.

behind the standard injection timing.

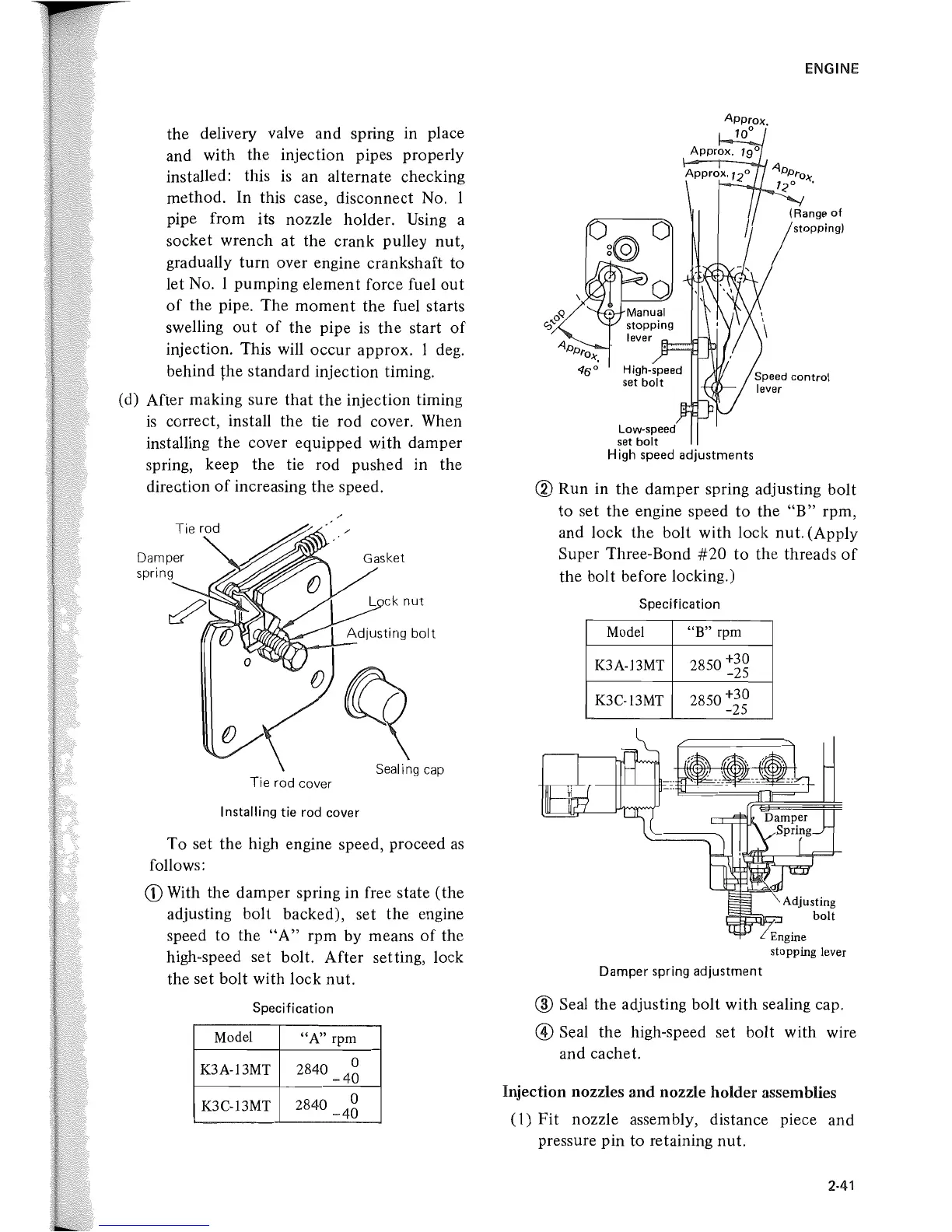

(d) After making sure

that

the injection timing

is

correct, install the tie rod cover. When

installing the cover equipped with damper

spring, keep the tie rod pushed in the

direction

of

increasing the speed.

Damper

Sealing cap

Tie rod cover

Installing tie rod cover

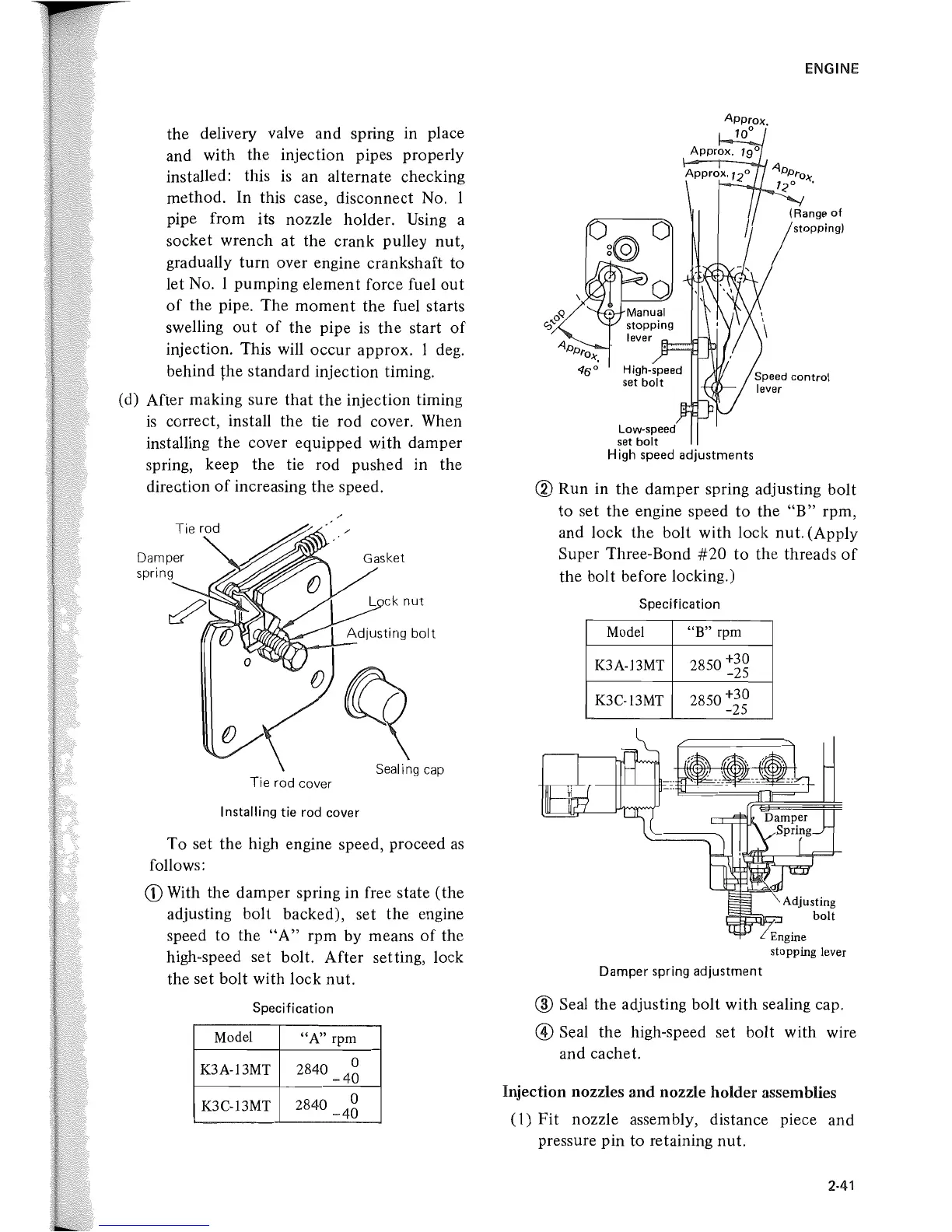

To set the high engine speed, proceed

as

follows:

CD

With the damper spring in free state (the

adjusting bolt backed), set the engine

speed

to

the

"A"

rpm by means

of

the

high-speed set bolt. After setting, lock

the set bolt with lock nut.

Specification

Model

"A"

rpm

K3A-13MT 2840

0

-40

K3C-13MT

2840

0

-40

Low-speed

set

bolt

High

speed adjustments

ENGINE

® Run in the damper spring adjusting bolt

to set the engine speed to the

"B"

rpm,

and lock the bolt with lock nut. (Apply

Super Three-Bond

#20

to the threads

of

the bolt before locking.)

Specification

Model

"B" rpm

K3A-13MT

2850 +30

-25

K3C-13MT

2850 +30

-25

Damper spring adjustment

® Seal the adjusting bolt with sealing cap.

@ Seal the high-speed set bolt with wire

and cachet.

Injection nozzles and nozzle holder assemblies

(1)

Fit nozzle assembly, distance piece and

pressure pin to retaining nut.

2-41

Loading...

Loading...