L

ENGINE

(2)

Fit

shim, spring and flange

to

body, and

tighten the body and retaining

nut

together

by torquing to the prescribed value.

(NOTE]

The body may be gripped in the vise,

but

not

the retaining nut. This

is

because

the nozzle might suffer distortion

if

the

nut

is

clamped between the vise jaws.

(3)

Fit

gasket and nipple

to

the body.

(4) When installing the nozzle holder assem-

blies, be sure to use new gaskets and tighten

the securing bolts to the prescribed torque

value.

(5)

Prior

to

installing the overhauled nozzle

holder assemblies, test each for "start-of-

injection" pressure, spray pattern, "after-

injection" dribbling and fuel atomization.

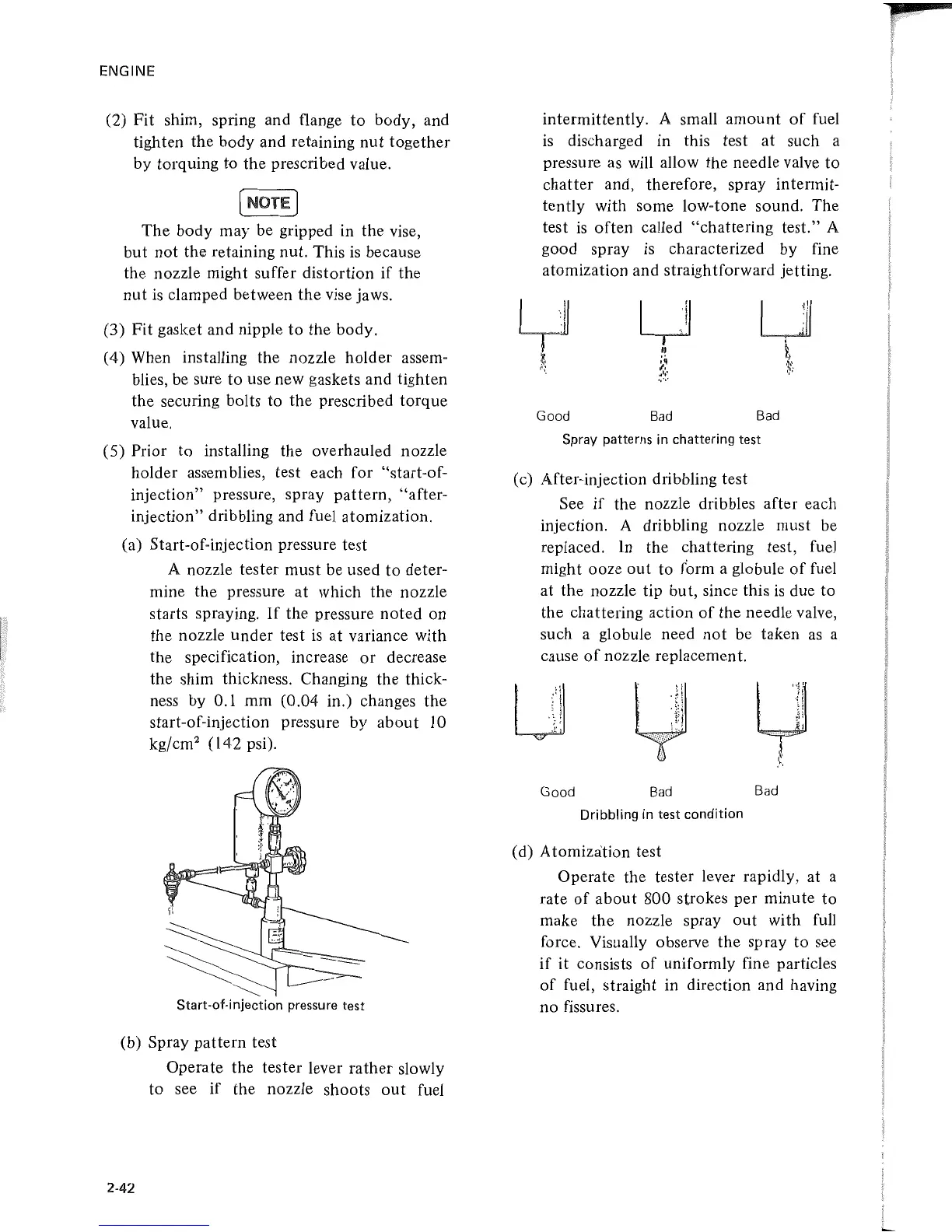

(a) Start-of-injection pressure test

A nozzle tester

must

be used to deter-

mine the pressure at which the nozzle

starts spraying.

If

the pressure

noted

on

the nozzle under test

is

at variance with

the specification, increase

or

decrease

the shim thickness. Changing the thick-

ness by 0.1 mm (0.04 in.) changes the

start-of-injection pressure by about

10

kg/cm

2

(142 psi).

Start-of-injection pressure

test

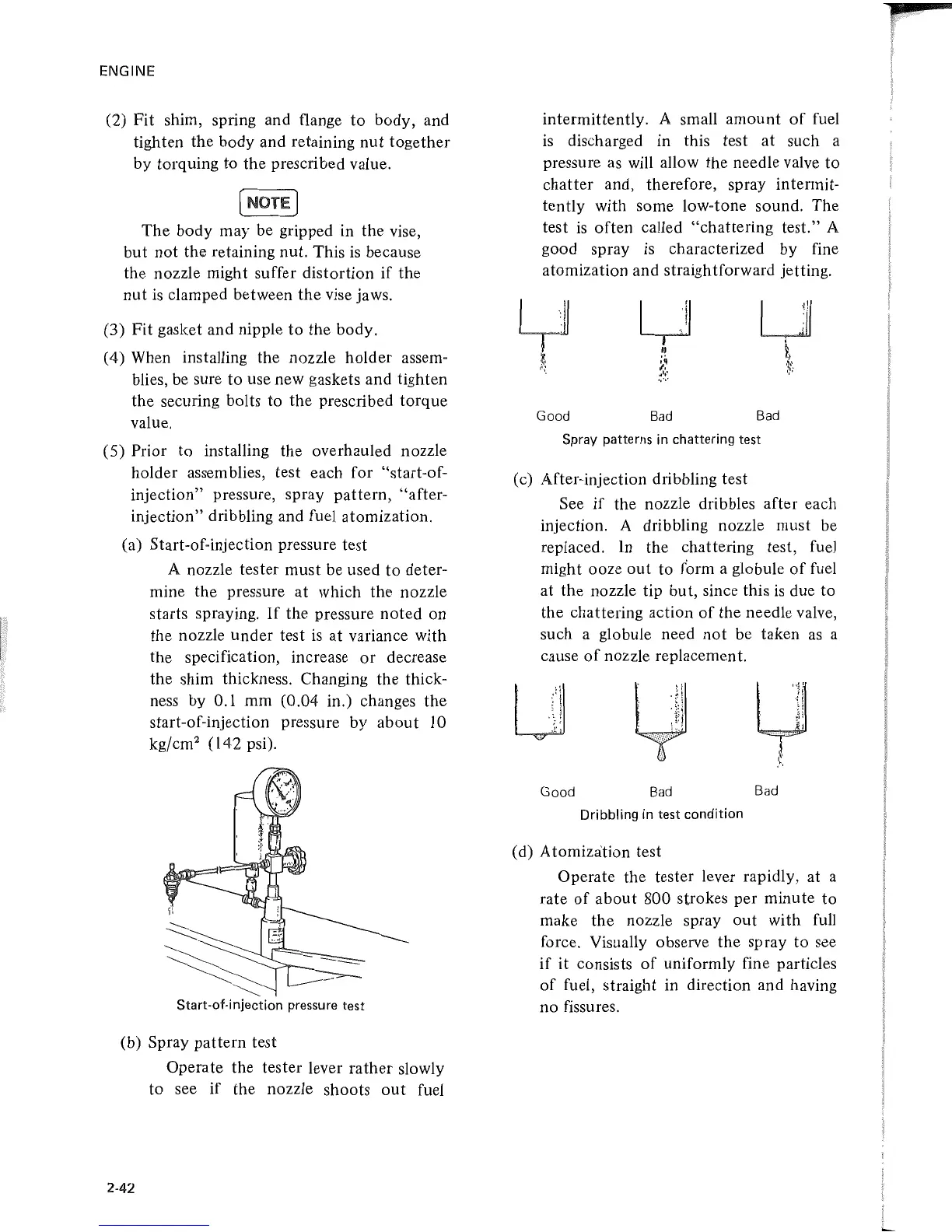

(b) Spray pattern test

2-42

Operate the tester lever rather slowly

to see

if

the nozzle shoots

out

fuel

intermittently. A small amount

of

fuel

is

discharged in this test at such a

pressure

as

will allow the needle valve to

chatter and, therefore, spray intermit-

tently with some low-tone sound. The

test

is

often called "chattering test." A

good spray

is

characterized by fine

atomization and straightforward jetting.

y

l,J

U

.J

1.,

~

~!

~~

,\,1

I':~

"I,'

,',I.:

.,','

Good

Bad

Bad

Spray

patterns

in

chattering

test

(c) After-injection dribbling test

See

if

the nozzle dribbles after each

injection. A dribbling nozzle must

be

replaced. In the chattering test, fuel

might ooze

out

to form a globule

of

fuel

at the nozzle tip but, since this

is

due to

the chattering action

of

the needle valve,

such a globule need

not

be taken

as

a

cause

of

nozzle replacement.

u

·····'·;·\

,l)

';'i

. ·-t

Good

i

,Iii

I

]!1

~

~

~ ~~

Bad

Bad

Dribbling in

test

condition

(d) Atomization test

Operate the tester lever rapidly, at a

rate

of

about

800 strokes per minute to

make the nozzle spray

out

with full

force. Visually observe the spray to see

if

it consists

of

uniformly fine particles

of

fuel, straight in direction and having

no fissures.

r

-

Loading...

Loading...