ENGINE

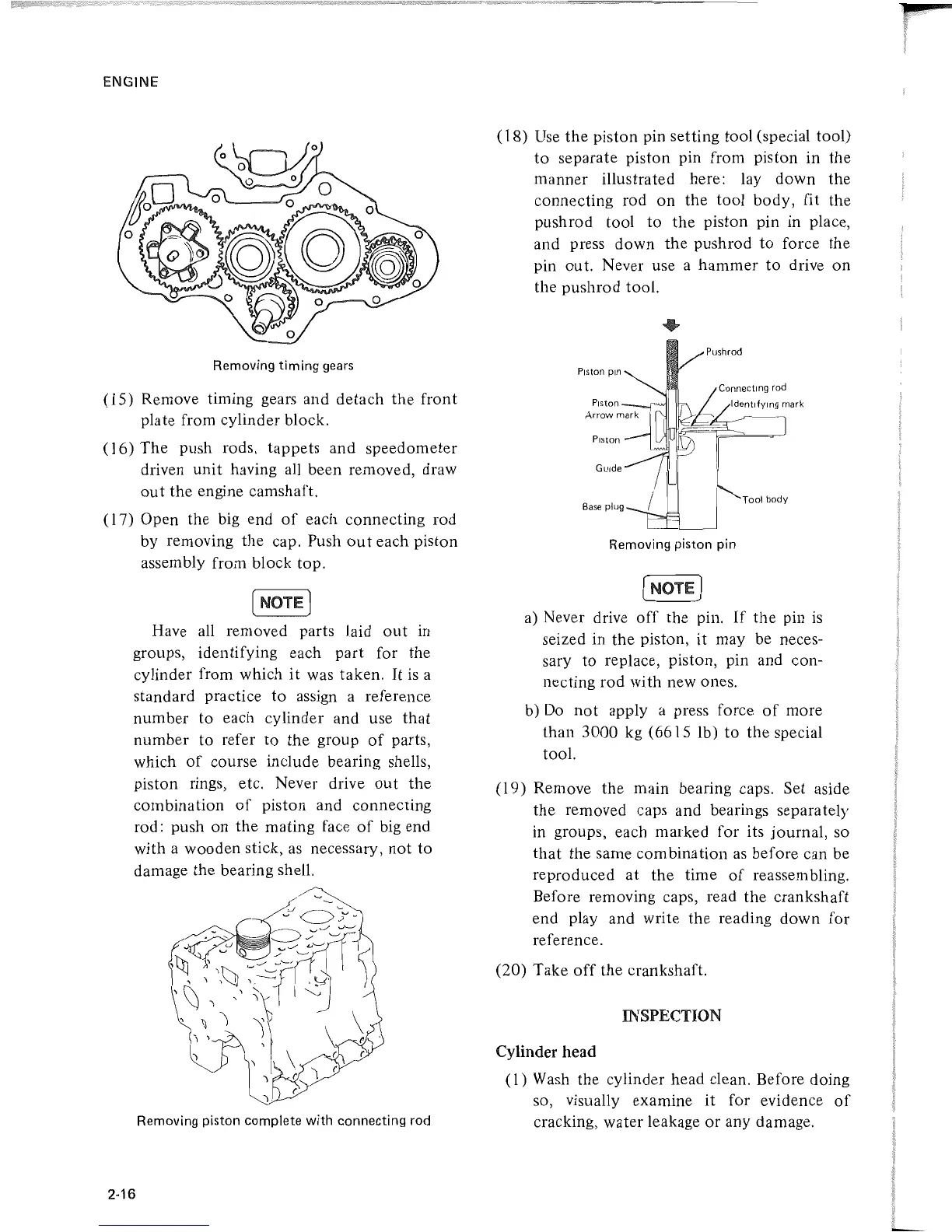

Removing

timing

gears

(15)

Remove timing gears and

detach

the

front

plate from cylinder block.

(16) The push rods, tappets and

speedometer

driven

unit

having all been removed, draw

out

the engine camshaft.

(17)

Open the big end

of

each connecting rod

by removing

the

cap. Push

out

each piston

assembly from block top.

[NOTE]

Have all removed parts laid

out

in

groups, identifying each

part

for the

cylinder from which

it

was taken.

It

is

a

standard practice to assign a reference

number

to

each cylinder and use

that

number

to

refer to the group

of

parts,

whIch

of

course include bearing shells,

piston rings, etc. Never drive

out

the

combination

of

piston and connecting

rod: push on the mating face

of

big end

with a wooden stick,

as

necessary,

not

to

damage the bearing shell.

Removing piston complete

with

connecting rod

2·16

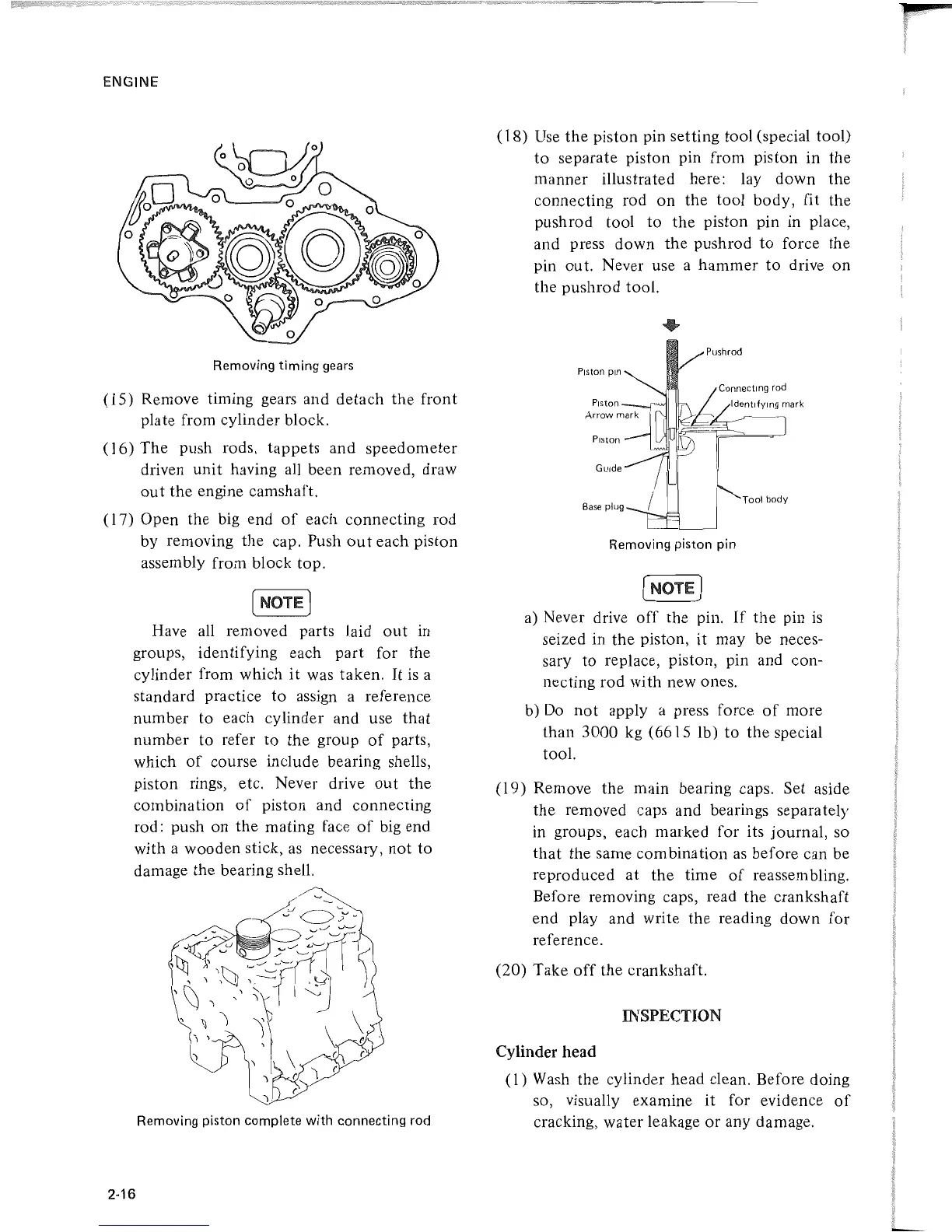

(18)

Use

the

piston pin setting tool (special tool)

to

separate piston pin from piston in the

manner illustrated here: lay down the

connecting rod

on

the tool

body,

fit the

pushrod tool

to

the

piston pin in place,

and press down the pushrod

to

force the

pin out. Never use a

hammer

to drive

on

the

pushrod

tool.

Removing piston pin

[NOTE]

a)

Never drive

off

the pin.

If

the pin

is

seized in the piston, it may be neces-

sary

to

replace, piston, pin and con-

necting rod with new ones.

b) Do

not

apply a press force

of

more

than

3000

kg (6615 Ib)

to

the special

tool.

(19)

Remove the main bearing caps. Set aside

the removed caps and bearings separately

in

groups, each marked for its journal, so

that

the same combination

as

before can be

reproduced at the time

of

reassembling.

Before removing caps, read the crankshaft

end play and write the reading down for

reference.

(20) Take

off

the crankshaft.

INSPECTION

Cylinder head

(1)

Wash

the

cylinder head clean. Before doing

so, visually examine

it

for evidence

of

cracking, water leakage

or

any damage.

F

Loading...

Loading...