h

n

y

.y

'0

is

lS

~r

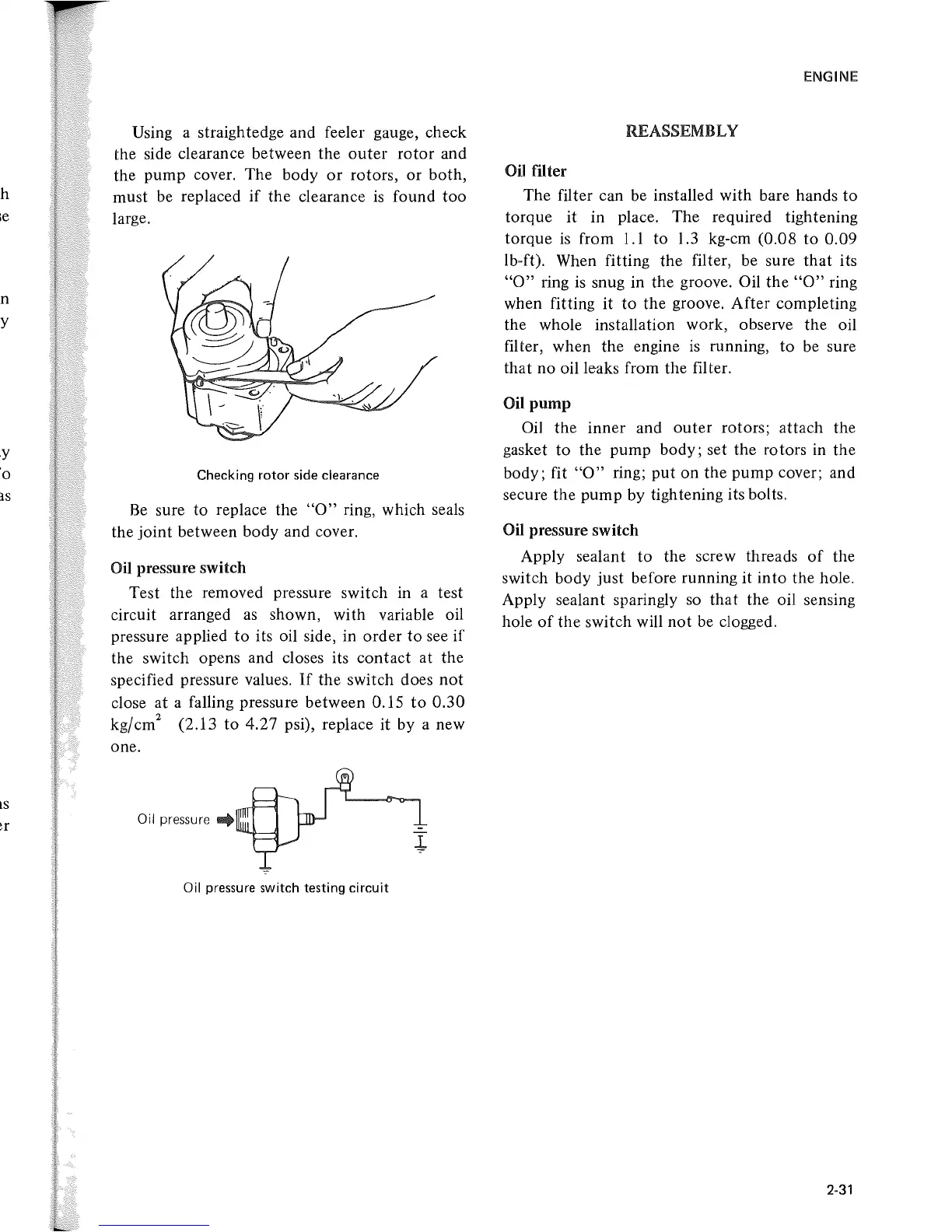

Using a straightedge and feeler gauge, check

the

side clearance between the

outer

rotor

and

the

pump

cover. The body

or

rotors, 01'

both,

must be replaced

if

the

clearance

is

found

too

large.

Checking rotor side clearance

Be

sure

to

replace the

"0"

ring, which seals

the

joint

between body and cover.

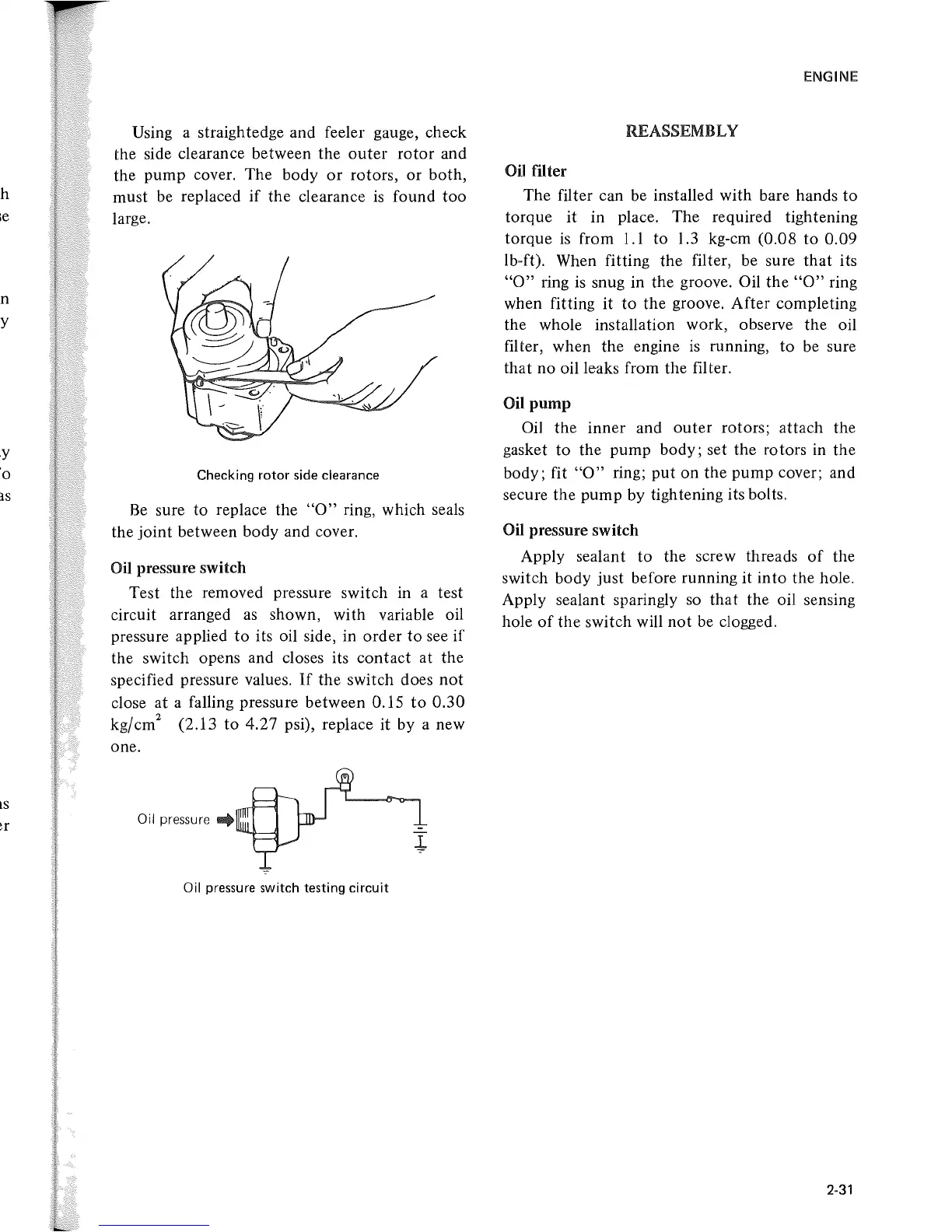

Oil pressure switch

Test

the

removed pressure switch in a test

circuit arranged

as

shown, with variable oil

pressure applied

to

its oil side, in

order

to

see

if

the switch opens and closes its

contact

at the

specified pressure values.

If

the switch does

not

close

at

a falling pressure between 0.15

to

0.30

kg/cm

2

(2.13

to

4.27 psi), replace it

by

a new

one.

Oil

pressure

..

Oil

pressure switch testing circuit

ENGINE

REASSEMBLY

Oil filter

The filter can be installed with bare hands

to

torque

it

in place. The required tightening

torque

is

from

1.1

to

1.3 kg-cm (0.08

to

0.09

Ib-ft). When fitting the filter, be sure

that

its

"0"

ring

is

snug in the groove. Oil

the

"0"

ring

when fitting

it

to

the

groove. After completing

the whole installation work, observe the oil

filter, when the engine

is

running, to be sure

that

no oil leaks from the filter.

Oil

pump

Oil the inner and

outer

rotors; attach the

gasket

to

the pump body; set the rotors in the

body; fit

"0"

ring;

put

on

the

pump

cover; and

secure the

pump

by tightening its bolts.

Oil pressure switch

Apply sealant

to

the screw threads

of

the

switch body just before running it

into

the hole.

Apply sealant sparingly so

that

the oil sensing

hole

of

the

switch will

not

be clogged.

2-31

Loading...

Loading...