ENGINE

Valves

(I)

Visually inspect the seating face and stem

of

each valve for wear and damage, and

repair

or

replace the valve,

as

necessary.

(2) A valve whose head

is

worn down to the

limit

of

"T"

value must be replaced.

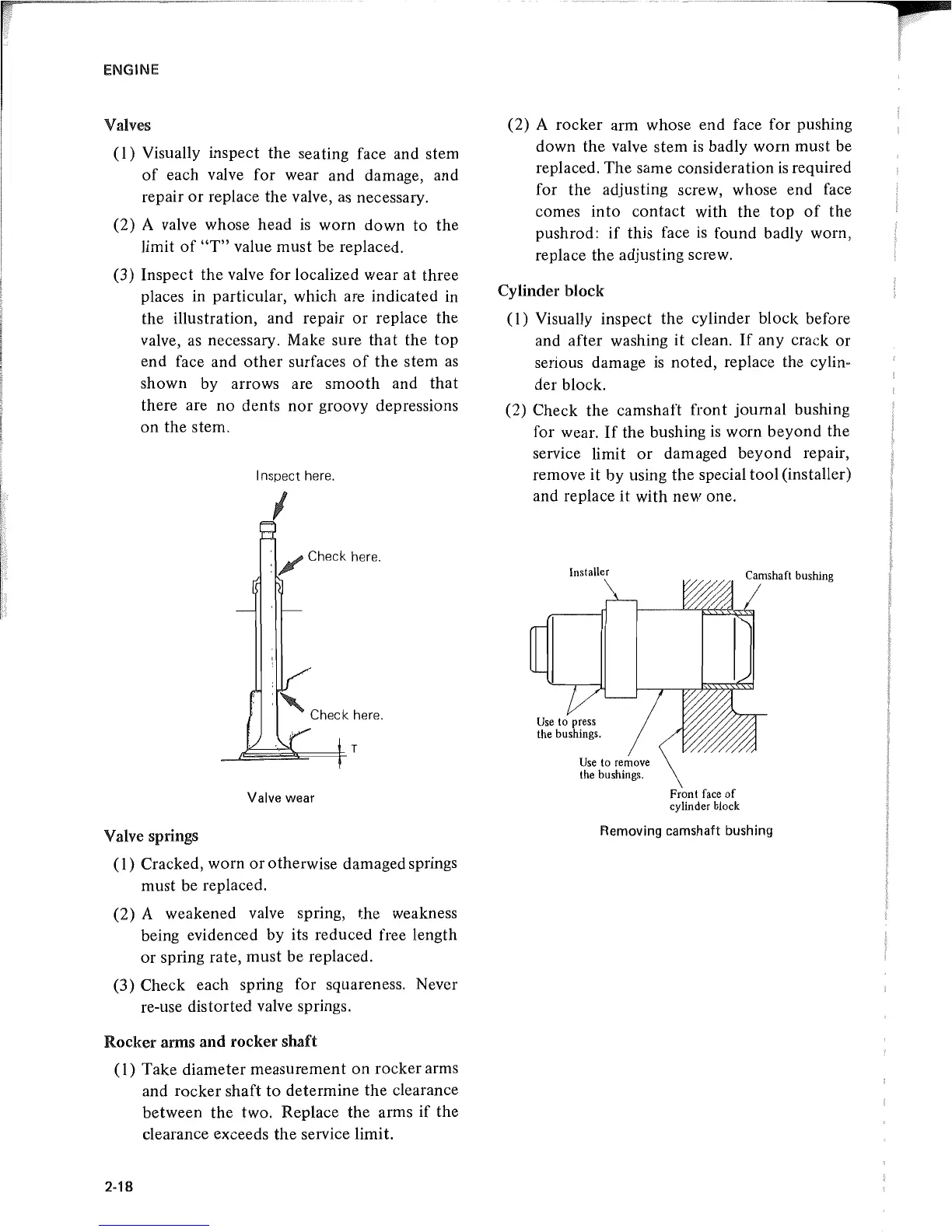

(3) Inspect the valve for localized wear at three

places in particular, which are indicated in

the illustration, and repair

or

replace the

valve,

as

necessary. Make sure tha t the

top

end face and

other

surfaces

of

the

stem

as

shown by arrows are

smooth

and

that

there are no dents

nor

groovy depressions

on the stem.

I

nspect

here.

Check

here.

Valve wear

Valve springs

(I)

Cracked, worn

or

otherwise damaged springs

must be replaced.

(2) A weakened valve spring, the weakness

being evidenced by its reduced free length

or

spring rate, must be replaced.

(3) Check each spring for squareness. Never

re-use distorted valve springs.

Rocker arms and rocker shaft

(1) Take diameter measurement on rocker arms

and rocker shaft

to

determine the clearance

between the two. Replace the arms

if

the

clearance exceeds the service limit.

2-18

(2) A rocker arm whose end face for pushing

down the valve stem

is

badly worn must be

replaced. The same consideration

is

required

for the adjusting screw, whose end face

comes

into

contact with the

top

of

the

pushrod:

if

this face

is

found badly worn,

replace the adjusting screw.

Cylinder block

(I)

Visually inspect the cylinder block before

and after washing

it

clean.

If

any crack

or

serious damage

is

noted, replace the cylin-

der block.

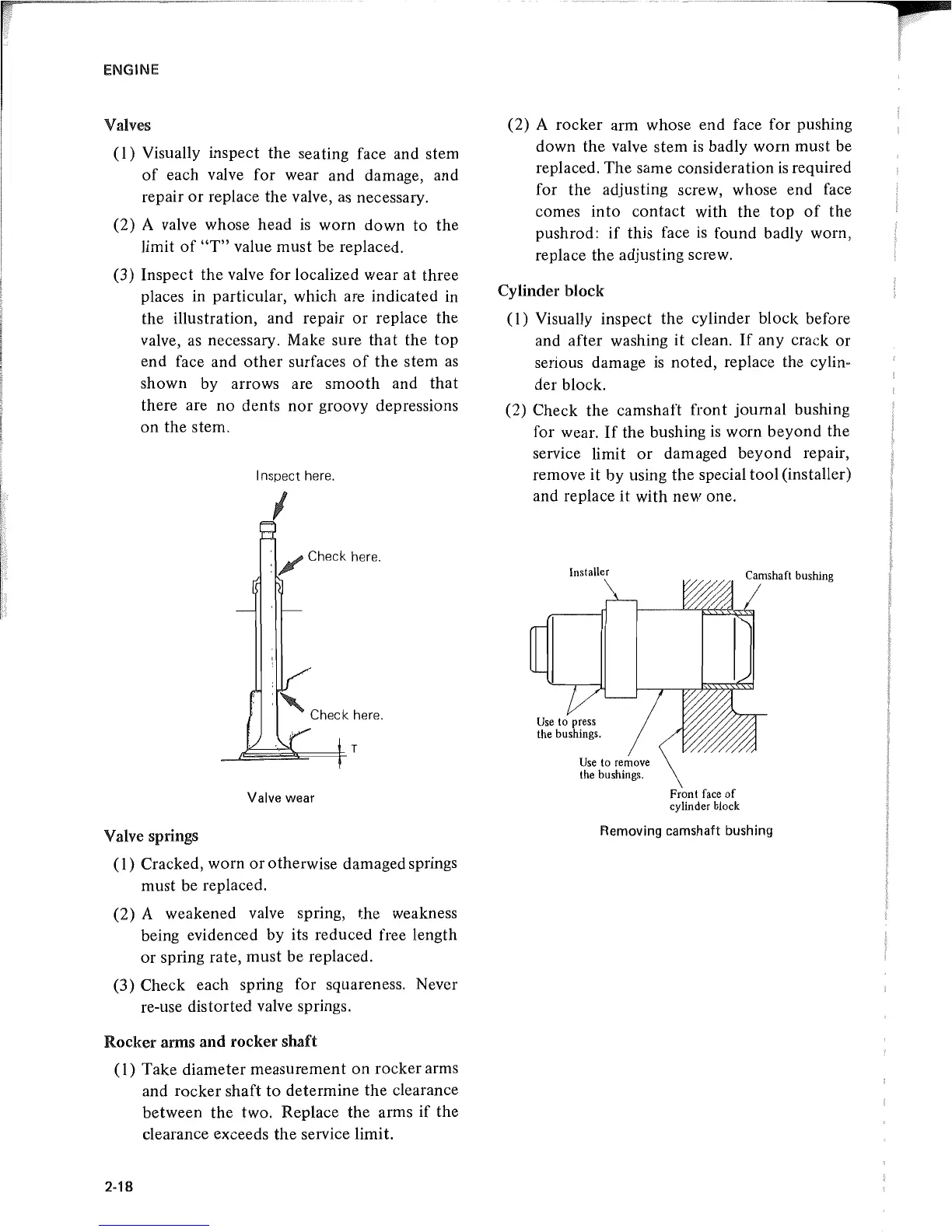

(2) Check the camshaft front journal bushing

for wear.

If

the bushing

is

worn beyond the

service limit

or

damaged beyond repair,

remove

it

by using the special tool (installer)

and replace it with new one.

Front

face

of

cylinder block

Removing camshaft bushing

Loading...

Loading...