Chapter 11: Failure Analysis

107

Mechanical Breakage/ Wear

Sometimes an engine fails because a part breaks.

There are generally three causes of a broken part, out-

side of the previously discussed engine failures. They

are abuse, wear, and manufacturing defects.

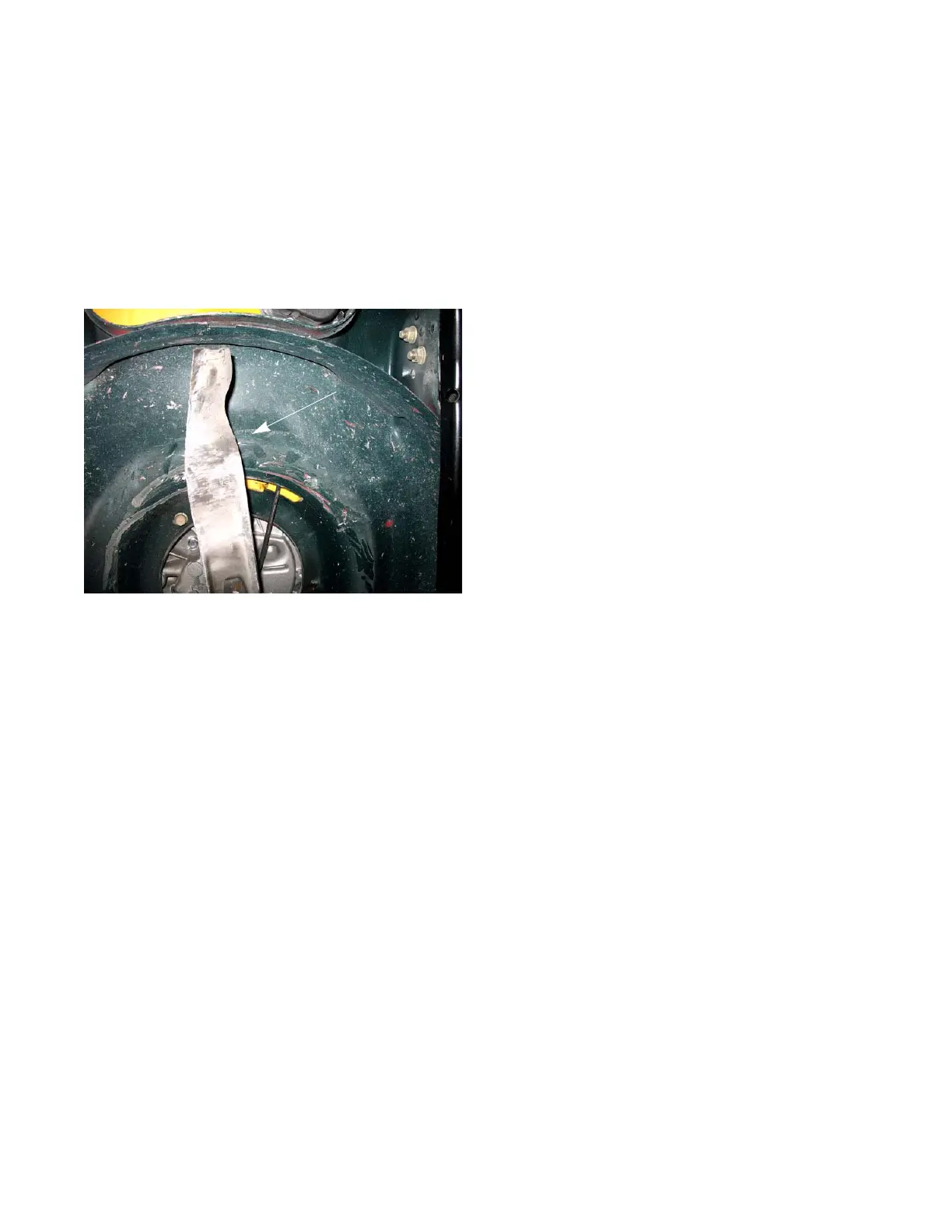

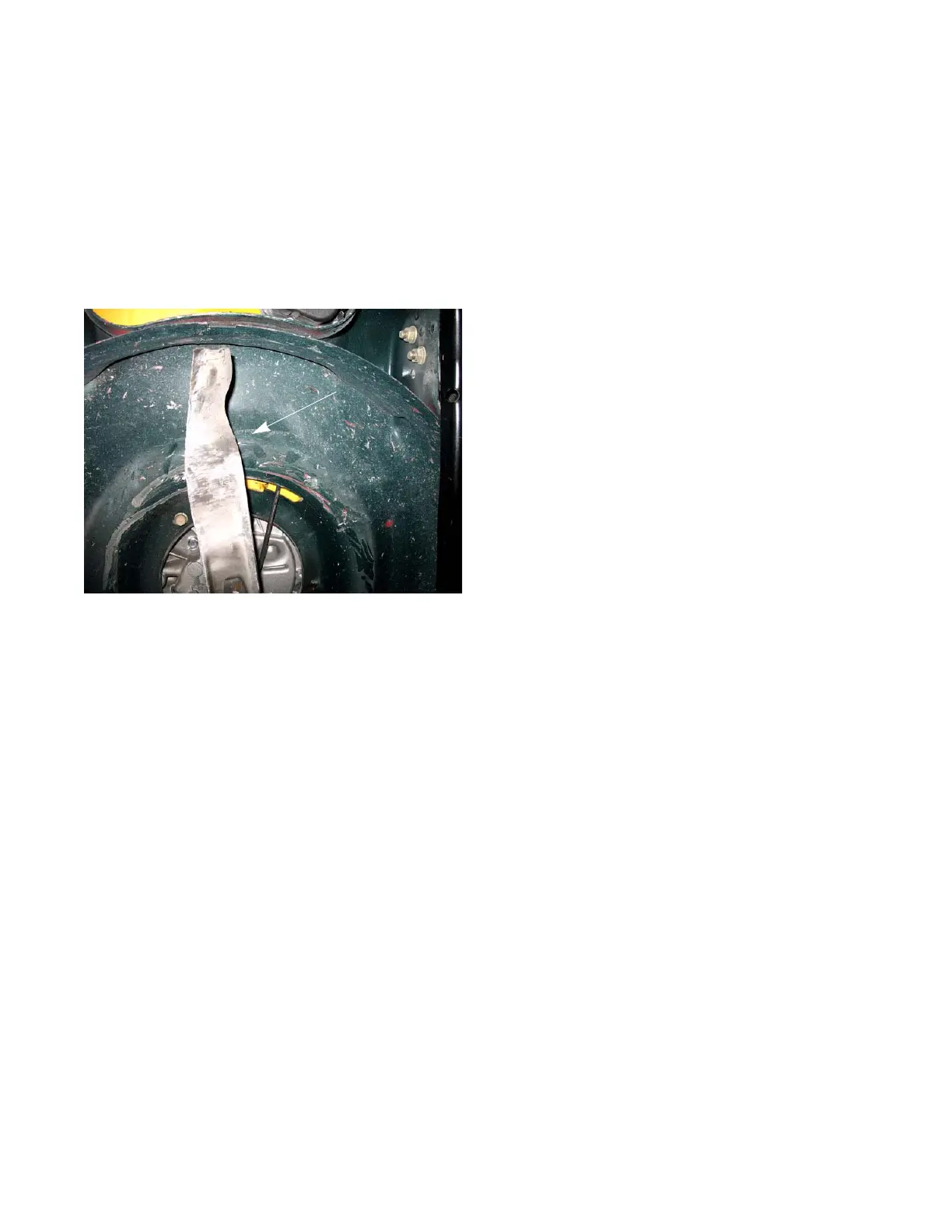

A very common way to abuse an engine is a bent

crankshaft. Crankshafts bend when they, or something

bolted to them hits an object. A prime example of this is

when a mower blade hits a rock. See Figure 11.13.

As the engine runs, there is friction between the mov-

ing parts. This friction wears down the parts. Lubrica-

tion slows the process, but wear can not be prevented.

Over time the parts wear to the point they break or fail

in some way. Car tires are a good example of wear. A

tire will only last for so many miles before all the rubber

is worn off and the tire goes flat. Bushings are another

example, they are designed to wear so that the wear of

other parts will be minimized.

Vibration issues have a “chicken and the egg” relation-

ship to mechanical failures. Which came first? Bent

crankshafts and imbalanced implements will cause

vibration issues. However a vibration issues, such as a

over speed or loose mounting bolts on the engine, can

shake an engine to pieces. The technician must find

the source of the vibration in order to properly diagno-

sis an engine.

Manufacturing defects are wrongly blamed for alot of

failed parts. A manufacturing defect is when a part is

made wrong. It could be a porous casting, parts

assembled wrong, the wrong parts used or so on. A

manufacturing defect will generally show up within the

first couple of hours of use.

Figure 11.13

Bent blade

Detonation/pre-ignition

Detonation is the undesirable condition of the fuel

spontaneously combusting in the combustion chamber

prior to the spark plug firing. In this state the flame front

from the detonation will start to travel through the com-

bustion chamber and a second flame front, from the

spark plug, will crash into it. The pressure differential

caused by this will send shock waves through the

engine. The shock wave cause a knocking or pinging

noise. This is why detonation is sometimes called

“knocking”, “spark knocking” or “pinging”. The shock

wave will also try to push the piston down against the

direction of rotation of the crankshaft.

The shock wave from detonation can cause piston fail-

ures (melting or breakage), piston skirt damage, con-

necting rod breakage and in extreme cases crankshaft

failures.

A build up of carbon deposits in the combustion cham-

ber will increase the compression ratio. This is a major

factor for the development of detonation. It insulates

the combustion chamber, allowing it heat up above nor-

mal operating temperatures.

Pre-ignition is similar to detonation, but on a smaller

scale. Pre-ignition is cause by a localized hot spot or a

hot deposit in the cylinder. As the fuel/air mixture is

drawn into the cylinder it is ignited. This creates pres-

sure that tries to push the piston down against the

direction of rotation of the crankshaft. The sounds and

damage created by this is the same as detonation.

www.mymowerparts.com

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

Loading...

Loading...