Chapter 7: Ignition System

73

Ignition module

The ignition system is either a capacitive discharge or a

inductive discharge magneto, depending on the appli-

cation, contained in a single module.

• The capacitive discharge has a three leg design.

• The inductive discharge magneto has a two leg

design.

• The magneto is energized by the passing of a

pair of magnets mounted in the flywheel.

• Ignition timing is set by the location of the fly-

wheel in relation to the crankshaft. Proper timing

is maintained by a steel key.

NOTE: Regardless of which type of magneto is

used, the test procedures are the same.

Module removal

1. Unplug the spark plug.

2. Remove the recoil assembly by following the

steps described in Chapter 6: Starter.

3. Lift the fan shroud off of the three studs that

locate it. See Figure 7.23.

4. Unplug the wire from the spade terminal on the

module or unplug the insulated bullet connec-

tors, depending on the production date of the

engine.

5. Remove the module using a 10mm wrench.

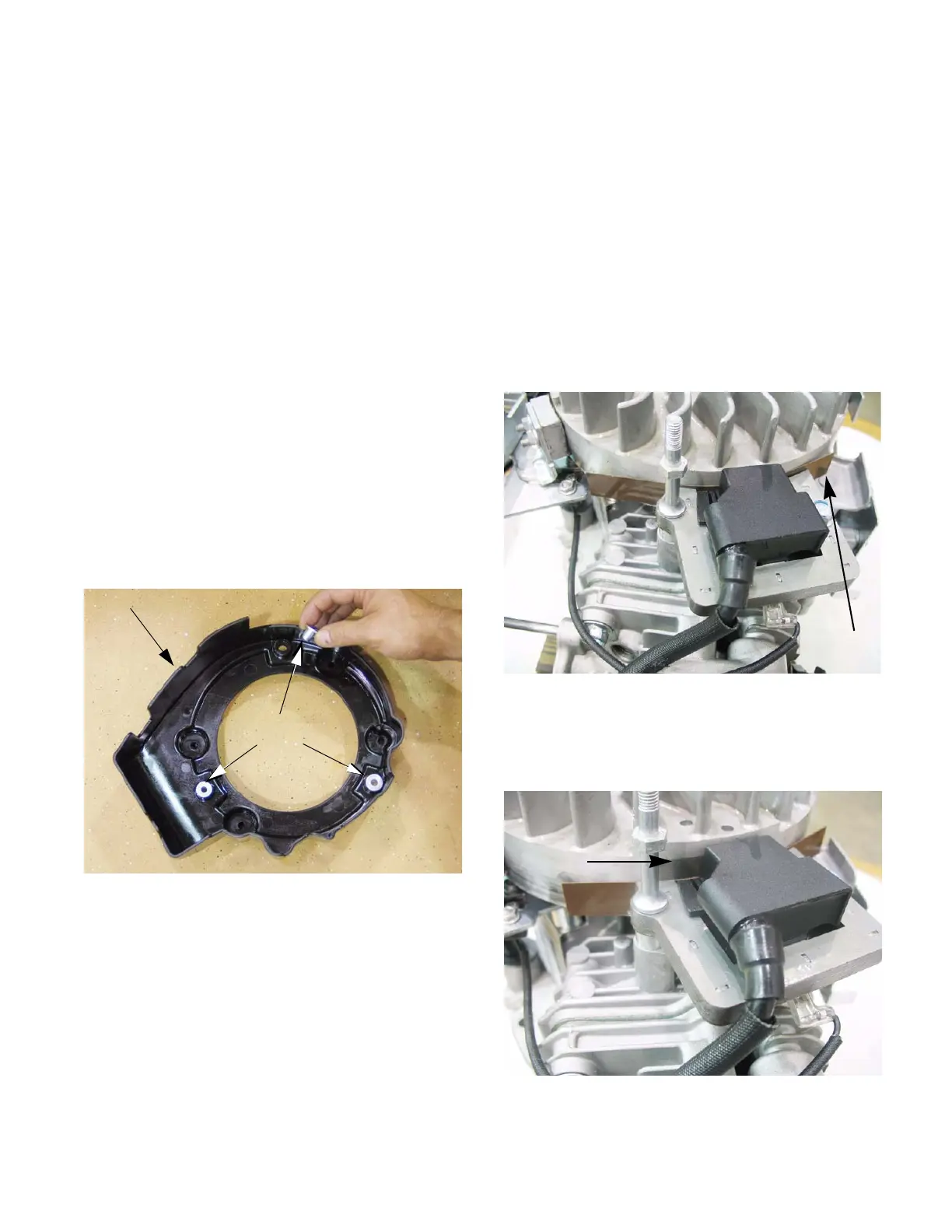

Figure 7.15

Fan shroud

Shoulder

bushings

Shoulder

bushings fit

over studs

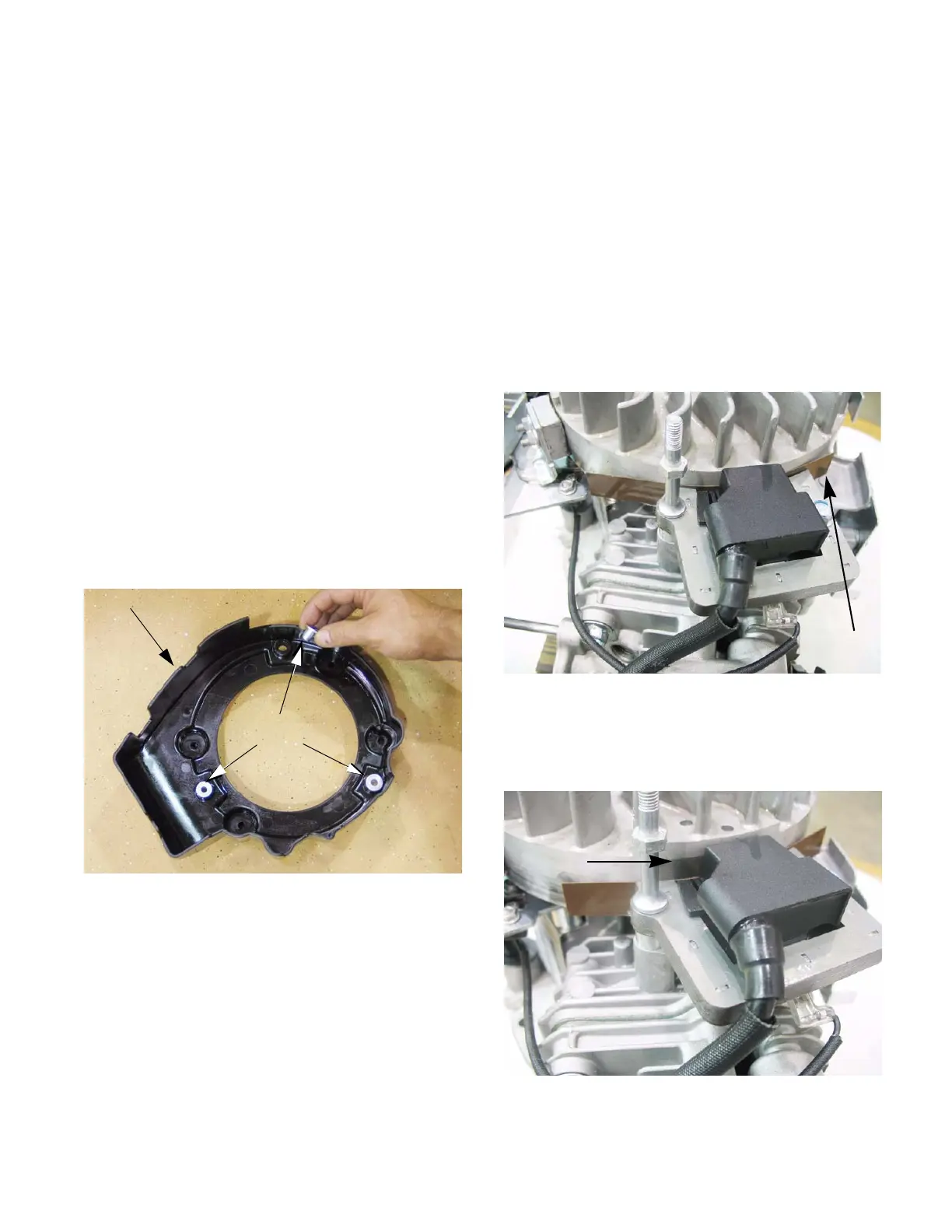

Installing the module and setting the air gap

NOTE: If just setting the air gap, loosen the

module mounting screws first then follow the

same steps as described below.

1. Rotate the flywheel so that the magnets are

away from where the module is mounted.

2. Install the module. Do not tighten the module

down.

3. Place a non-ferrous feeler gauge between the

module and the flywheel. See Figure 7.16.

NOTE: The air gap should be .008”-.016” (.2-

.4mm).

4. Rotate the flywheel so that the magnets align

with the legs of the module while holding the

feeler gauge in place. See Figure 7.17.

Figure 7.16

.010” feeler

gauge

Figure 7.17

Magnet

www.mymowerparts.com

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

Loading...

Loading...