Chapter 10: Crankshaft, piston and Connecting Rod

93

Bearings

There are two bearings to inspect; a plain bearing in

the sump and a ball bearing in the cylinder block. To

inspect the bearings:

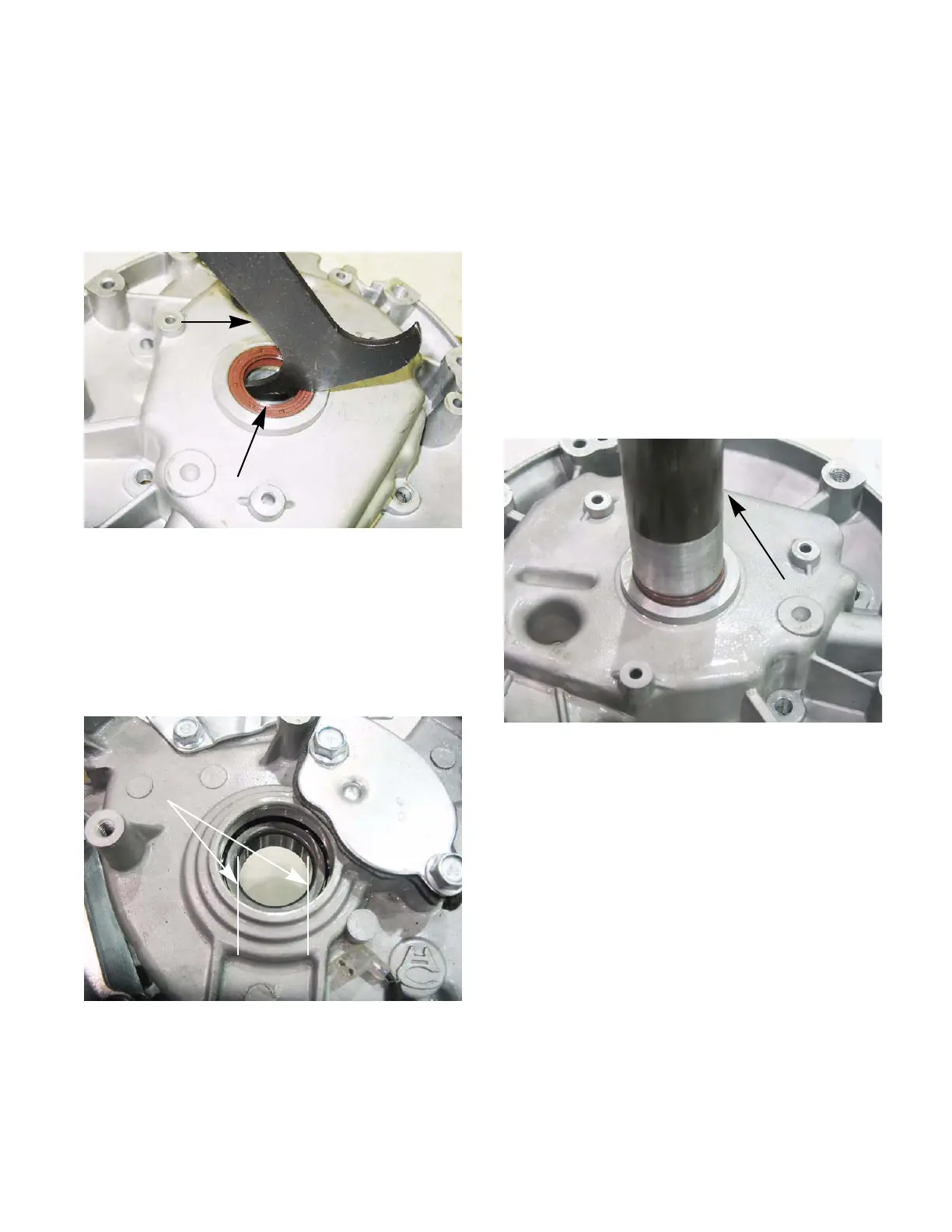

1. Remove the sump and cylinder block oil seals

using a seal puller. See Figure 10.19.

2. Inspect the bearing surface for galling,

scratches, metal transfer or any other signs of

damage.

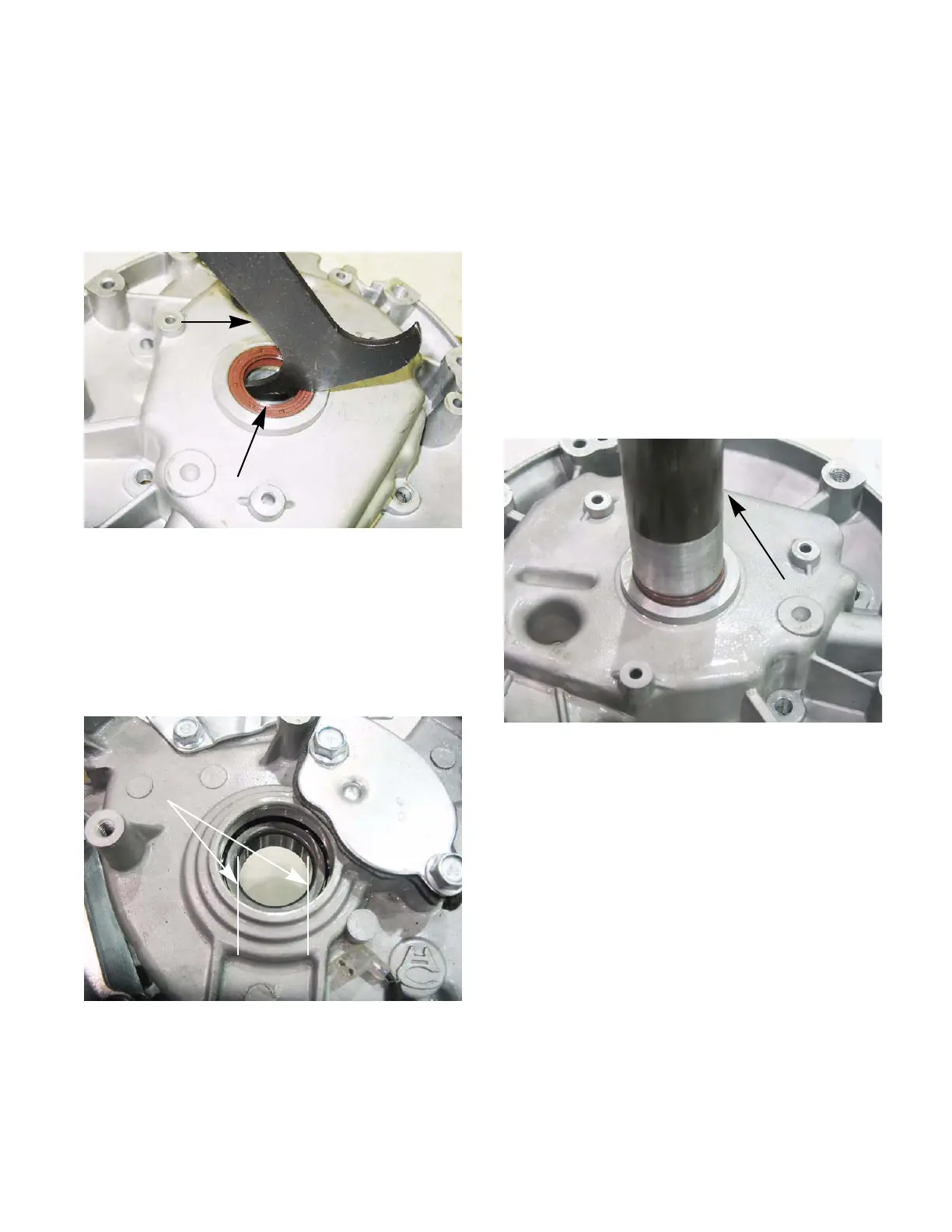

3. Measure the inside diameter of the bearings and

compare to the chart at the end of this chapter.

See Figure 10.20.

NOTE: The bearing can not be serviced. If they

are bad the engine must be short blocked.

Figure 10.19

Sump oil seal

Seal puller

Figure 10.20

Measure the

bearing ID

Reassembly

1. Clean the cylinder

1a. Remove all gasket material from all mating

surfaces.

1b. Clean the cylinder and sump.

2. Oil seals

2a. Install a new oil seal in the cylinder block.

NOTE: A piece of 1” schedule 40 PVC pipe can

be used as a seal driver.

2b. Install a new seal in the sump.

See Figure 10.21.

NOTE: Use a Troy-Bilt tiller seal service tool #

TWX-4006 to install the sump oil seal.

Figure 10.21

Troy-Bilt seal drive

www.mymowerparts.com

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

Loading...

Loading...