2205B0JE-DA-J-N_2014.05.

5 Maintenance and Inspection

Screw Compressor J-series 5.4 Disassembly and Assembly of the Compressor

5-57

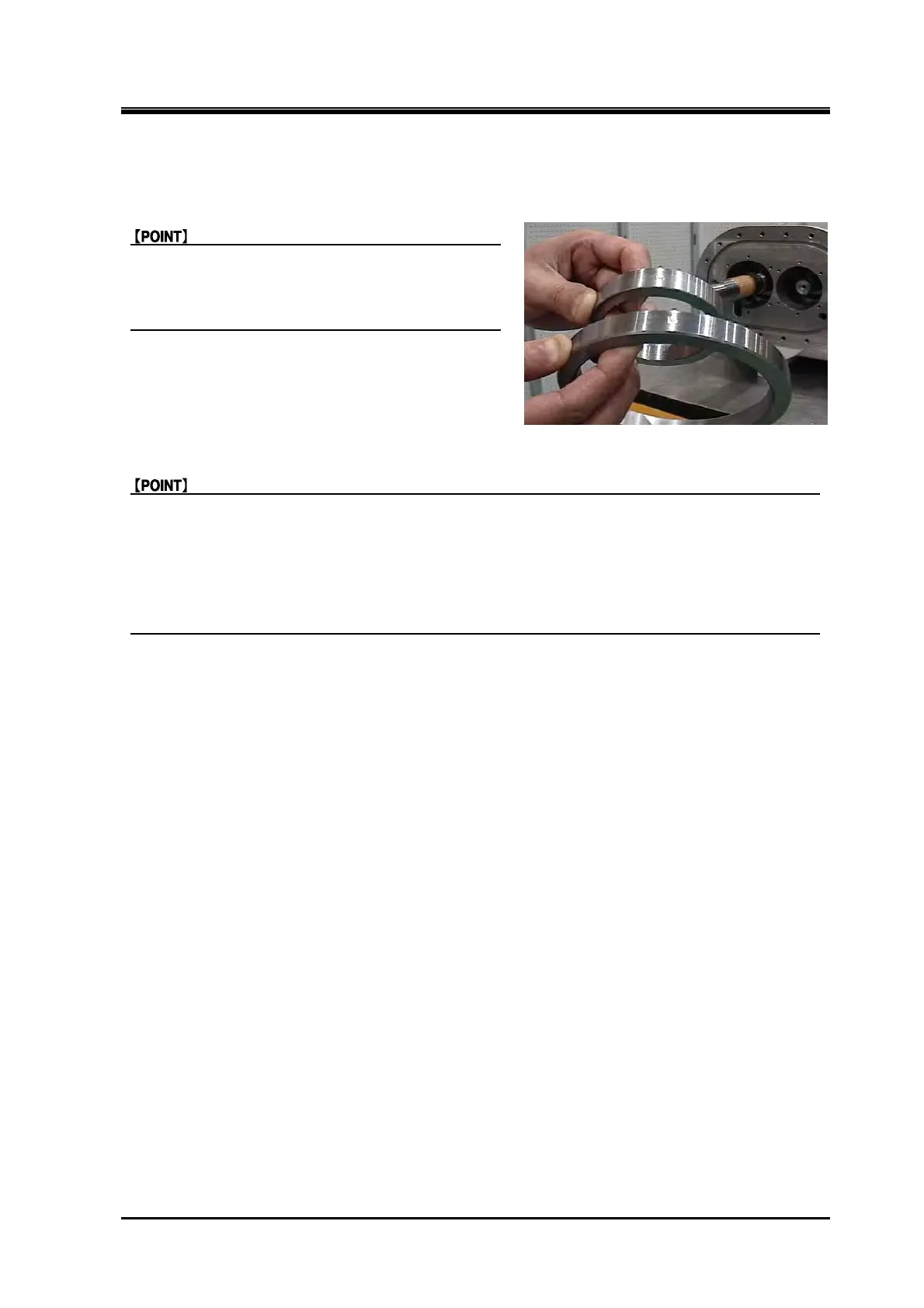

Thrust bearing outer race spacers M and F (only for 170J/220J)

/ thrust bearing alignment spacers M and F

The thrust bearing outer race spacers and thrust

bearing alignment spacers have a stamped mark

of M

or F.

1. When installing the thrust bearing outer race

spacers and thrust bearing alignment spacers,

direct the upper side of the stamped letter toward

the machine.

Locknuts M and F / torsional slip washers / lock washers M and F

If the locknut is tightly fastened and the rotor is not able to rotate, it secures no end clearance

and the thrust bearing will be damaged.

If no end clearance is secured, do not tighten the locknut further and replace the thrust bearing

alignment spacer or insert a shim of appropriate thickness between the thrust bearing alignment

spacer and the inner race of the thrust bearing to secure appropriate end clearance.

For further details, refer to “5.4.20 Adjustment of End Clearance” in this manual chapter 5.

1. Align the lock washer claw to the locknut groove and bend the lock washer claw using a

screwdriver.

Thrust bearing gland for male rotor (170J)

1.

Facing the cast out part of the thrust bearing gland for male rotor down, attach it to the oil drain

groove of the bearing head.

Hexagon head screw (M8×30/M12×50/M16×65)/conical spring washer (M8/M12/M16)

1.

The conical spring washer must be attached after adjustment of end clearance.

2. Tighten the hexagon socket head cap screw (M8×30/M12×50/M16×65) evenly and lightly using a

wrench.

3. For further details, refer to "5.4.20 Adjustment of End Clearance".

Loading...

Loading...