2205B0JE-DA-J-N_2014.05.

5 Maintenance and Inspection

Screw Compressor J-series 5.4 Disassembly and Assembly of the Compressor

5-75

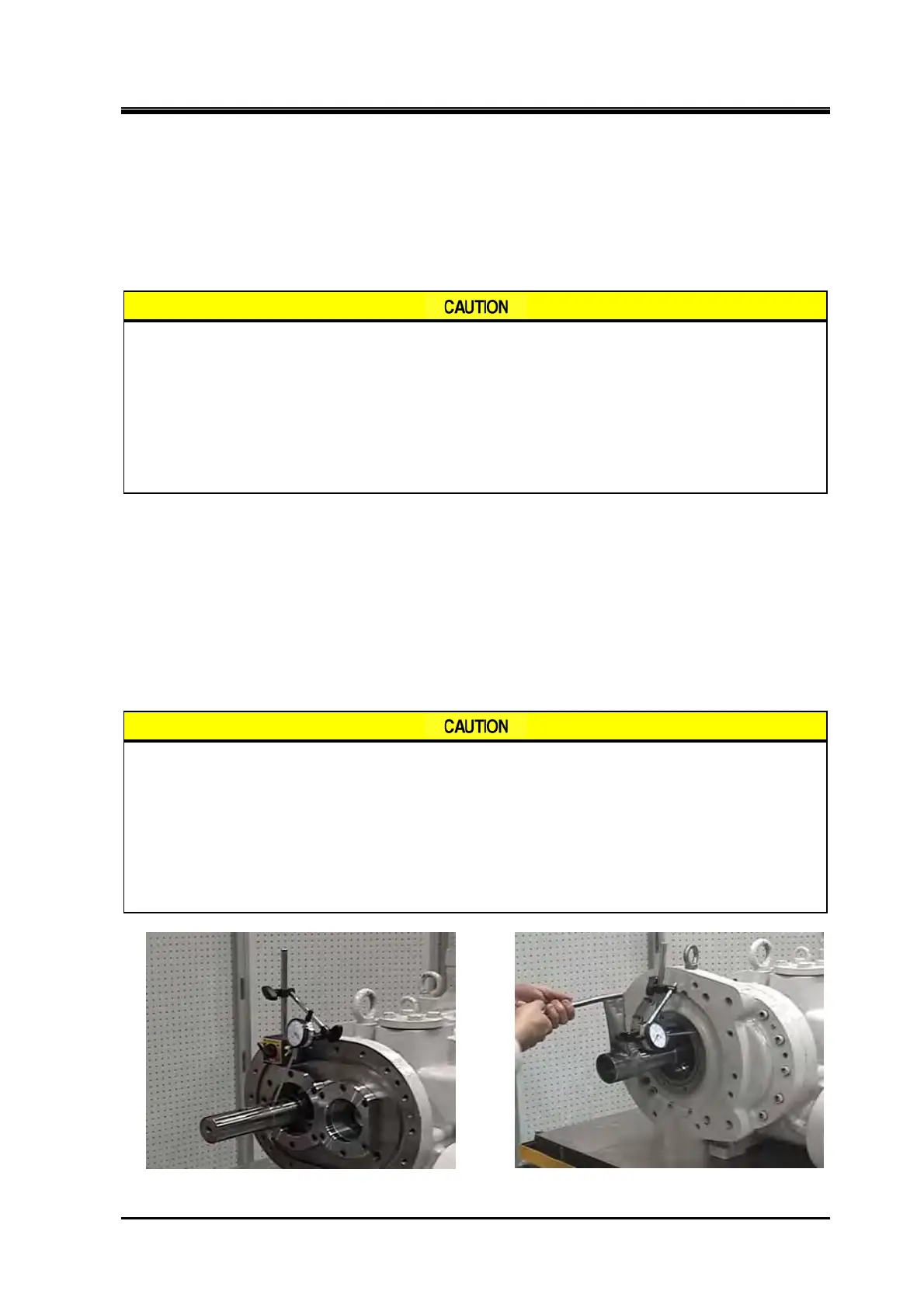

5.4.25 Inspection for Runout Male Rotor Shaft

1. Mount a dial gauge on the bearing head flange face and attach the point to the seal portion of the

male rotor.

2. Check the runout of the seal portion of male rotor shaft by rotating it.

Specification: 0.03/turn or less

If the measured runout is larger than specified, some foreign matters may be

jammed between the parts, the locknut tightening torque may be excessive, or

the accuracy of parallelism deviation for the thrust adjustment spacer is not

satisfactory.

Disassemble the parts and inspect the thrust adjustment spacer, thrust spacer,

thrust bearing, and locknut to eliminate any possible causes. Do not tighten the

locknut fully in one cycle. Tighten it evenly several times while changing the

combination of engagement between tightening tool claw and locknut groove.

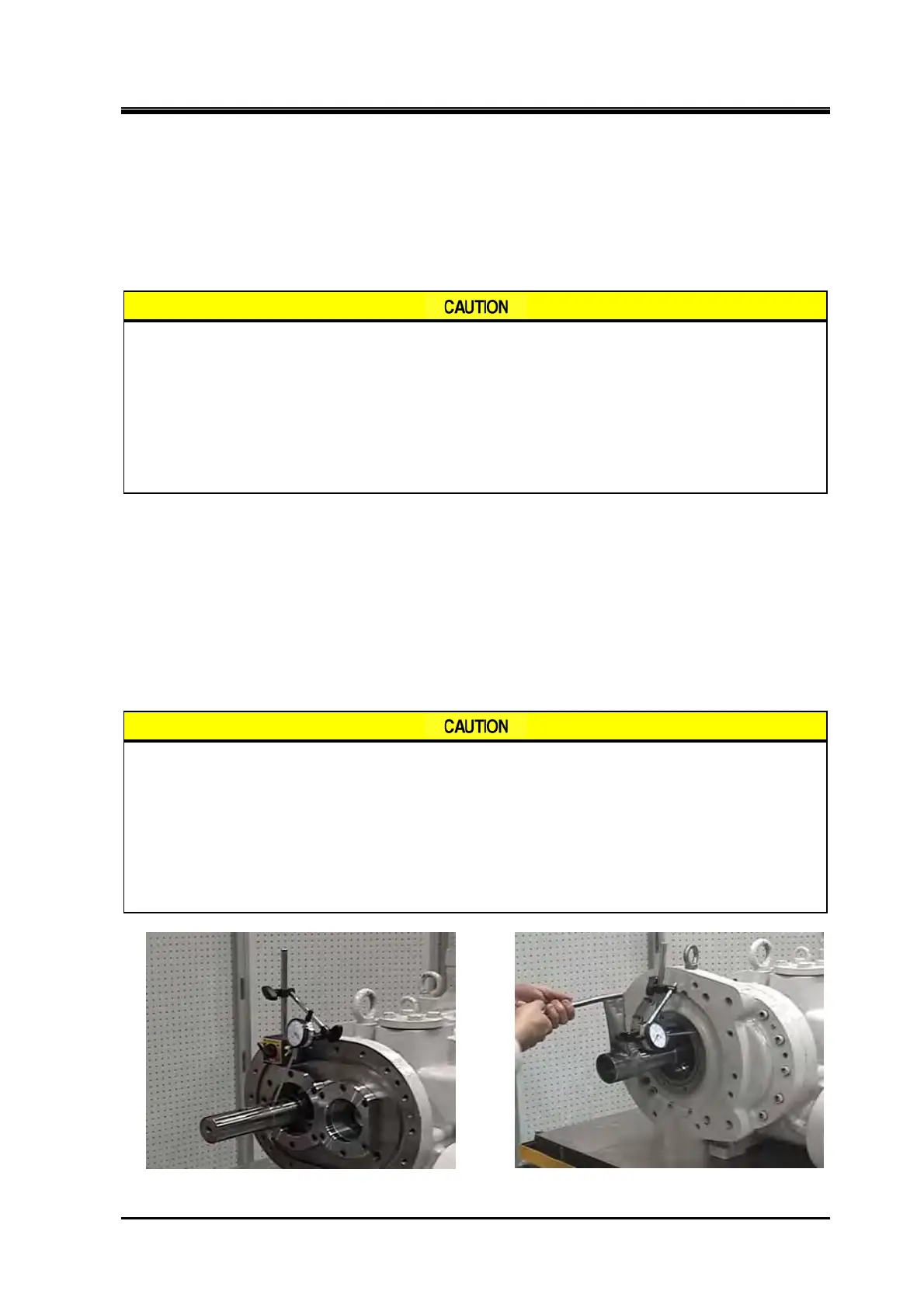

5.4.26 Inspection for Runout of Seal Cover Mount Face (Bearing

Cover)

1. Mount a dial gauge to the shaft of the male rotor and attach the point on the flange face of bearing

cover.

2. Check the runout of the seal cover mount face for the bearing cover by rotating the male rotor

shaft.

Specification: 0.05/turn or less

If the measured runout is larger than specified, some foreign matters may be

jammed between the parts, or the locknut tightening torque may be excessive, or

the accuracy of parallelism deviation for the thrust adjustment spacer is not

satisfactory.

Disassemble the parts and inspect the thrust adjustment spacer, thrust spacer,

thrust bearing, and locknut to eliminate any possible causes. Do not tighten the

locknut fully in one cycle. Tighten it evenly several times while changing the

combination of engagement between tightening tool claw and locknut groove.

Check the runout of the male rotor shaft Check the runout of the seal cover mount face

Loading...

Loading...