215

Built-in Outputs Section 7-1

7-1-8 Feeding Wrapping Material: Interrupt Feeding

Specifications and Operation

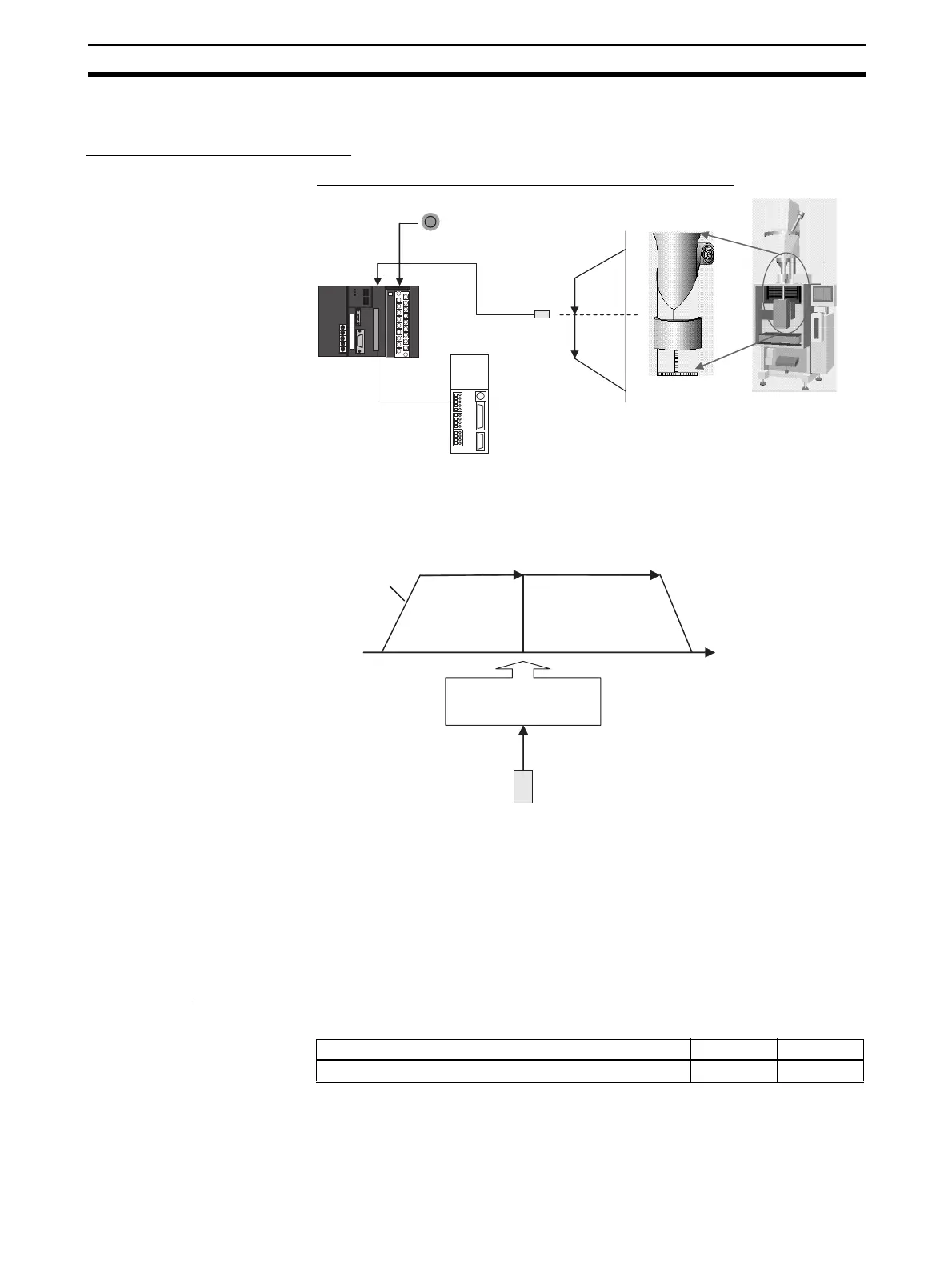

Feeding Wrapping Material in a Vertical Pillow Wrapper

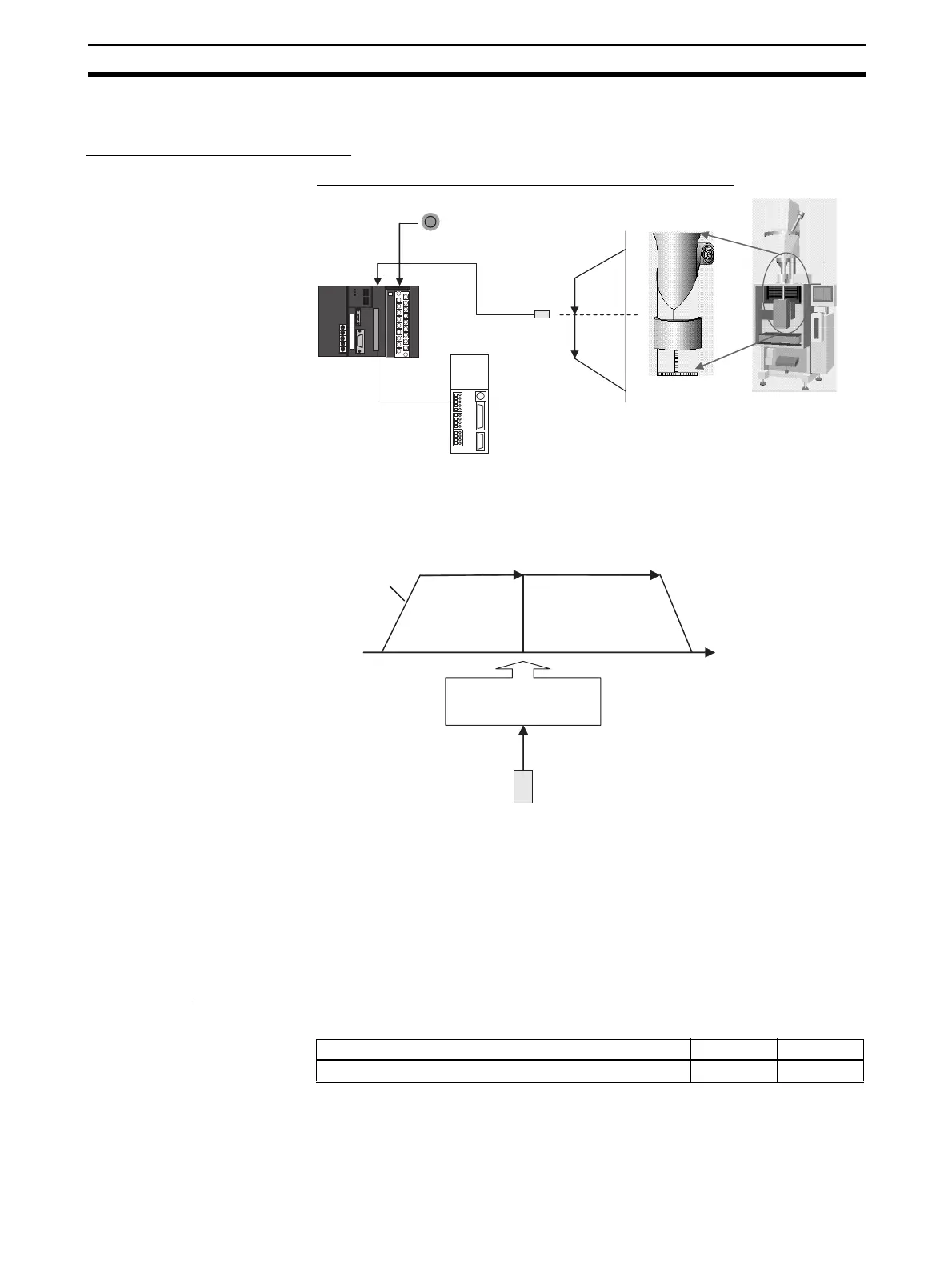

Operation Pattern Speed control is used to feed wrapping material to the initial position. When

the marker sensor input is received, fixed-distance positioning is performed

before stopping.

Operation

1,2,3... 1. Speed control is used to feed wrapping material to the initial position when

the Start Switch (CIO 00000) is activated.

2. When the Marker Sensor Input (IN0) is received, PLS2(887) is executed in

interrupt task 140.

3. Fixed-distance positioning is executed with PLS2(887) before stopping.

Preparation

PLC Setup Settings

Note The interrupt input setting is read when the power supply is turned ON.

Start Switch (CIO 000000)

Pulse output

(CW/CCW)

Marker sensor

(Built-in input IN0)

Position

control

Speed

control

10000 Hz

500 Hz/4 ms

(2710 hex)

(01F4 hex)

Speed

control

Position control

5,000 (1388 hex) pulses

output before stopping.

Input interrupt task

executes PLS2(887)

Marker sensor

input (IN0)

Setting details Address Data

Enable using built-in input IN0 as an interrupt input. 060 0011 hex

Loading...

Loading...