6-45

6-7 Object Dictionary

OMNUC G5-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

6

Drive Profile

These objects set the gear ratio.

Set the numerator of the electronic gear in the object for sub-index 1 (Motor revolutions). If the set

value is 0, the encoder resolution will be set as the numerator.

Set the denominator of the electronic gear in the object for sub-index 2 (Shaft revolutions).

Set the gear ratio to between 1/1,000 and 1,000. If the gear ratio is out of range, an Object Setting

Error (Error No. 93.0) will occur.

If the set value of Motor revolutions is 0, the encoder resolution will be set as the numerator, even

for fully-closed control.

Refer to Electronic Gear Function on page 7-18 for details.

This object sets the position command offset.

In Cyclic synchronous position mode (csp), the offset value is added to the Target position (607A

hex) for use as the target position in controlling the position.

The value obtained by adding the value of this object (60B1 hex) and speed feed-forward value

calculated from the internal position command and related objects (3110 hex and 3111 hex) is

used as a speed feed-forward input value for the speed command which is calculated by

comparing the internal position command and the position feedback. The Block Diagram for

Position Control Mode on page 6-7 shows the relationship of above description. Refer to 11-11

Feed-forward Function on page 11-29 for details.

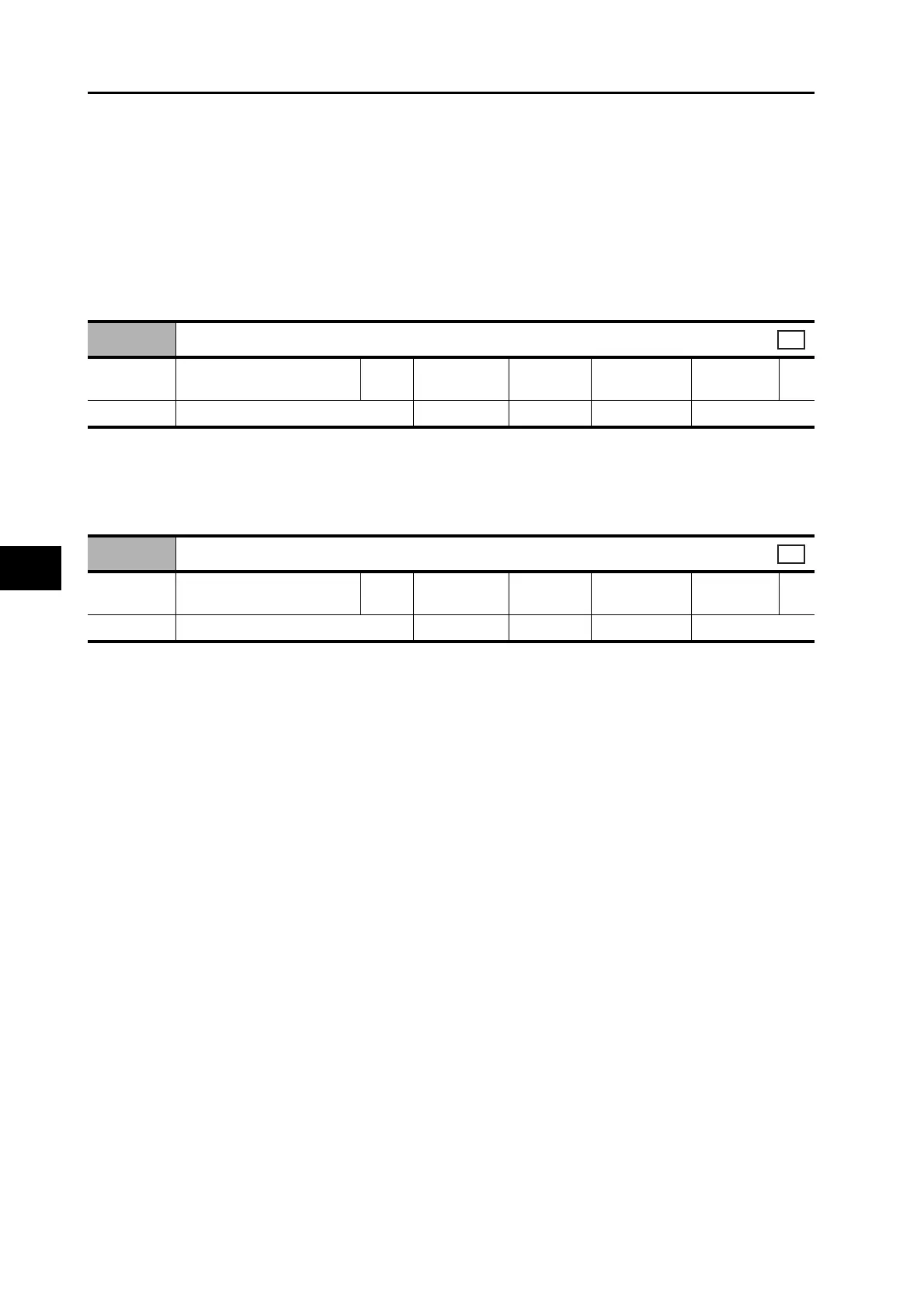

60B0 hex

Position offset

Range

−2147483648 to

2147483647

Unit

Command

units

Default 0 Attribute A

Size 4 bytes (INT32) Access RW PDO map Possible

csp

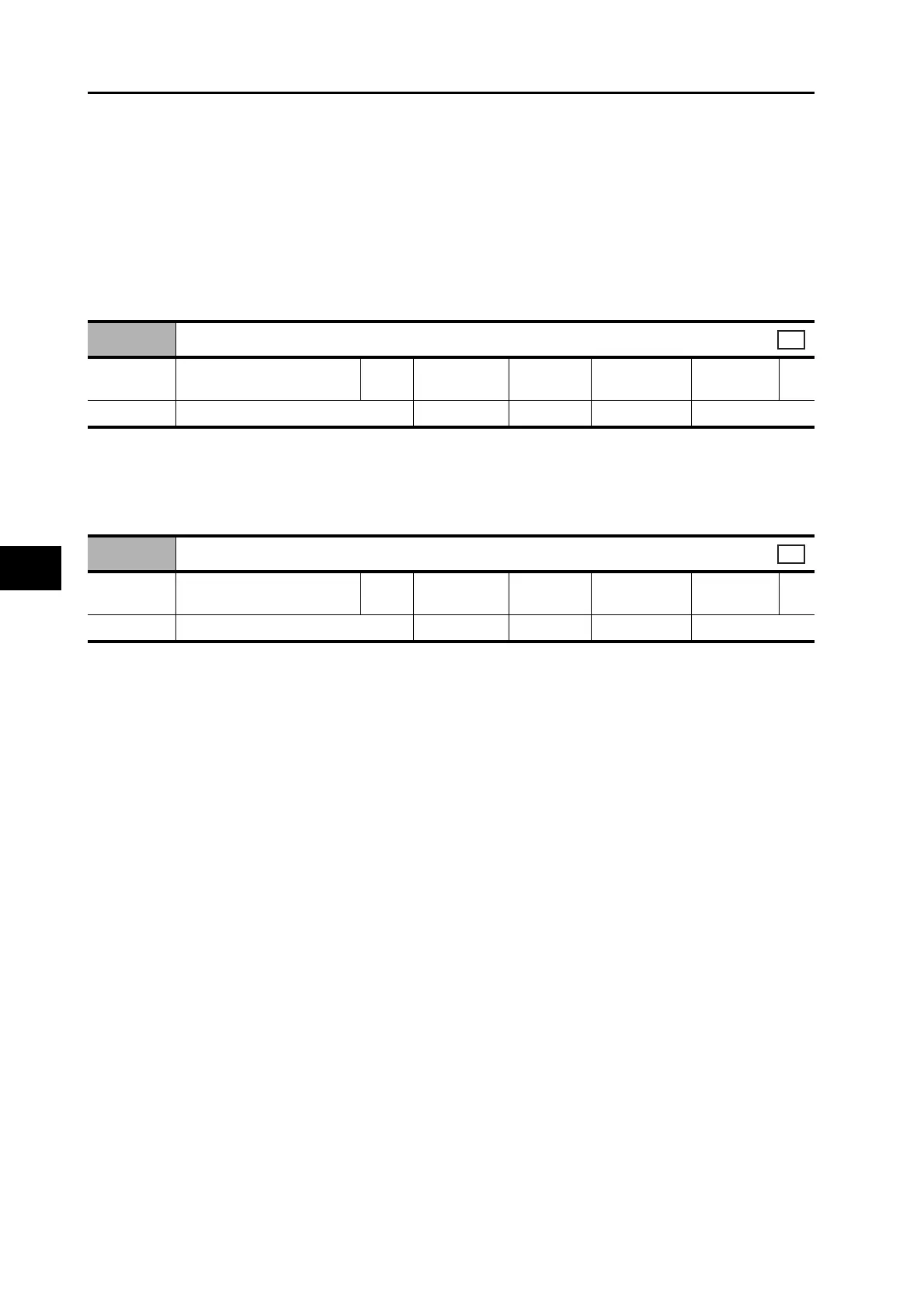

60B1 hex

Velocity offset

Range

−2147483648 to

2147483647

Unit

Command

units/s

Default 0 Attribute A

Size 4 bytes (INT32) Access RW PDO map Possible

csp

Loading...

Loading...