Chapter 5

5-7

Troubleshooting

5-3 Troubleshooting

If an error occurs in the machinery, check the type of error using the alarm indicators

and operation status, verify the cause, and take appropriate countermeasures.

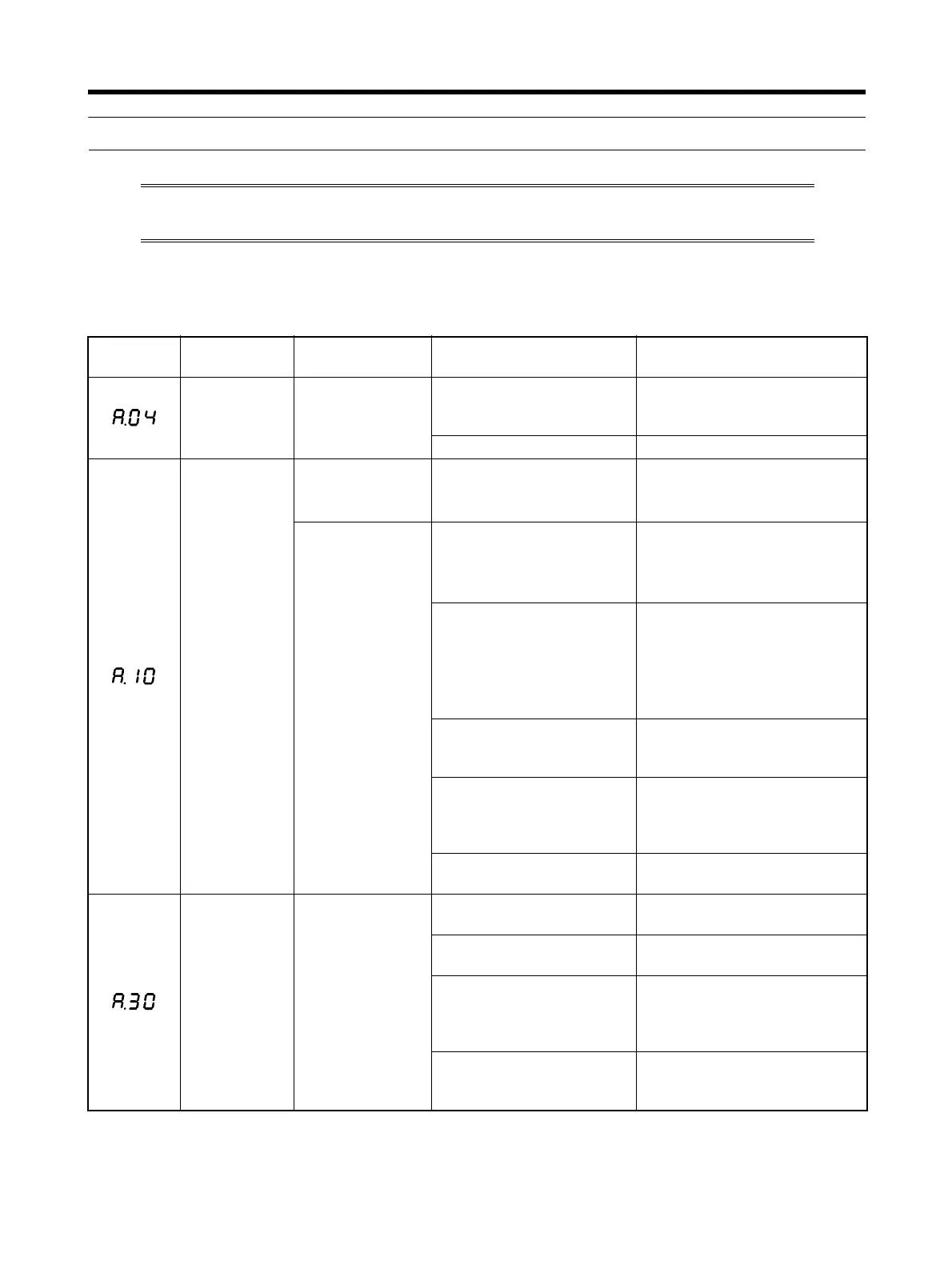

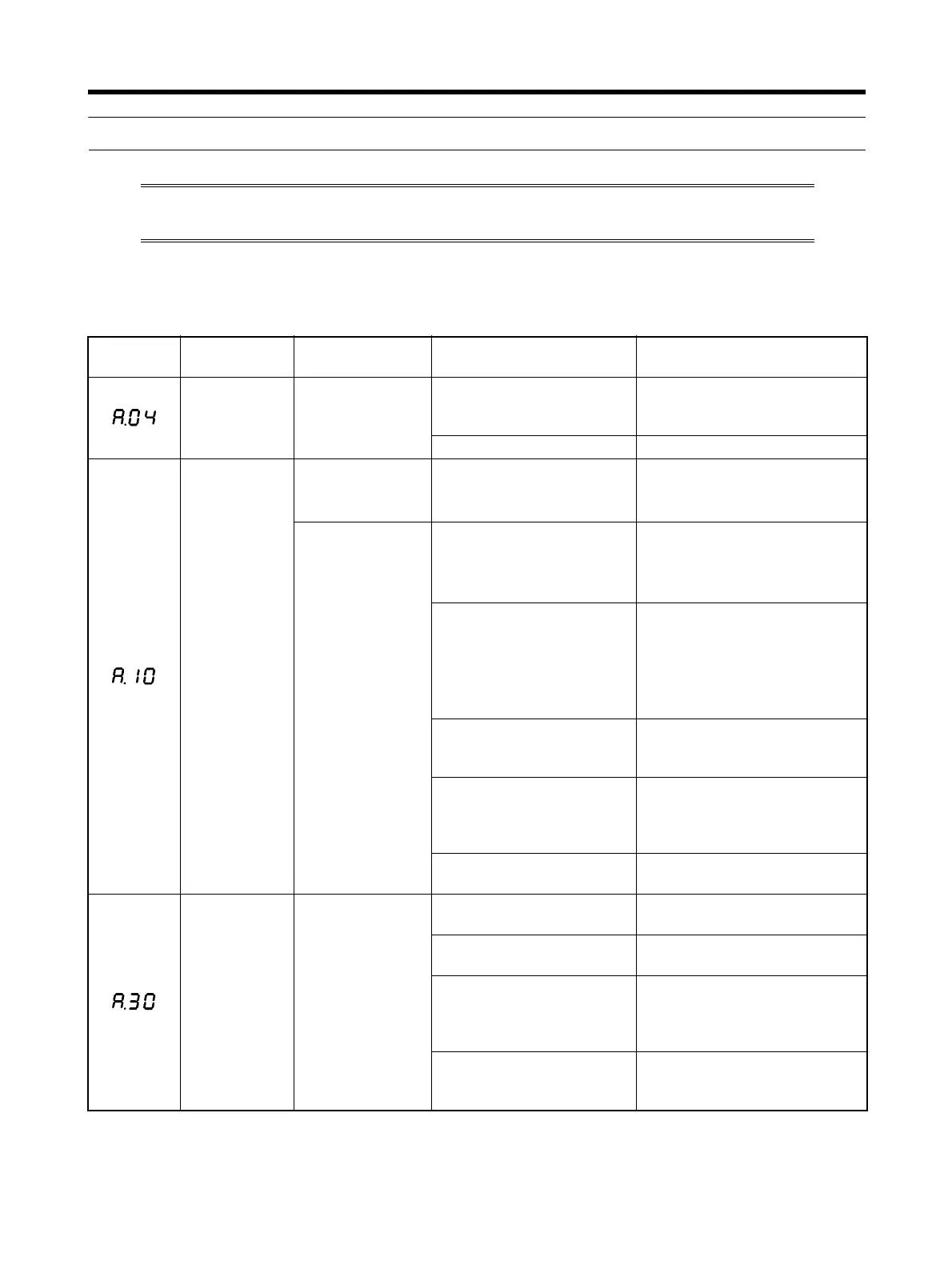

5-3-1 Error Diagnosis Using Alarm Display

Display Error Status when

error occurs

Cause of error Countermeasures

Parameter

setting error

Occurs when con-

trol circuit power

supply is turned

ON.

A value outside of the set-

ting range was previously

set in the parameters.

Reset the parameters within

the setting range.

Control panel error Replace the Servo Driver.

Overcurrent Occurs when

power supply is

turned ON.

Control panel error

Main circuit transistor mod-

ule error

Replace the Servo Driver.

Occurs when

servo is turned

ON.

Current feedback circuit

error

Main circuit transistor mod-

ule error

Replace the Servo Driver.

Servomotor power line is

short-circuited or grounded

between phases.

Repair the short-circuited or

grounded wire.

Measure the insulation resis-

tance at the Servomotor and, if

there is a short-circuit, replace

the Servomotor.

Miswiring between U-

phase, V-phase, W-phase,

and ground.

Correct the wiring.

Servomotor winding is

burned out.

Measure the winding resis-

tance, and if the winding is

burned out, replace the Servo-

motor.

Operating above rated out-

put.

Lighten the load.

Regeneration

error

Occurs during

operation.

Error in the regenerative

circuit parts.

Replace the Servo Driver.

External Regeneration

Resistor is disconnected.

Replace the External Regener-

ation Resistor.

There is a short-circuit

missing between B2 and

B3, but the external circuit

resistor is not connected.

Correctly connect the external

circuit resistor (between B1

and B2).

Setting error in Pn600

(regeneration resistor

capacity).

Set Pn600 correctly.

Loading...

Loading...