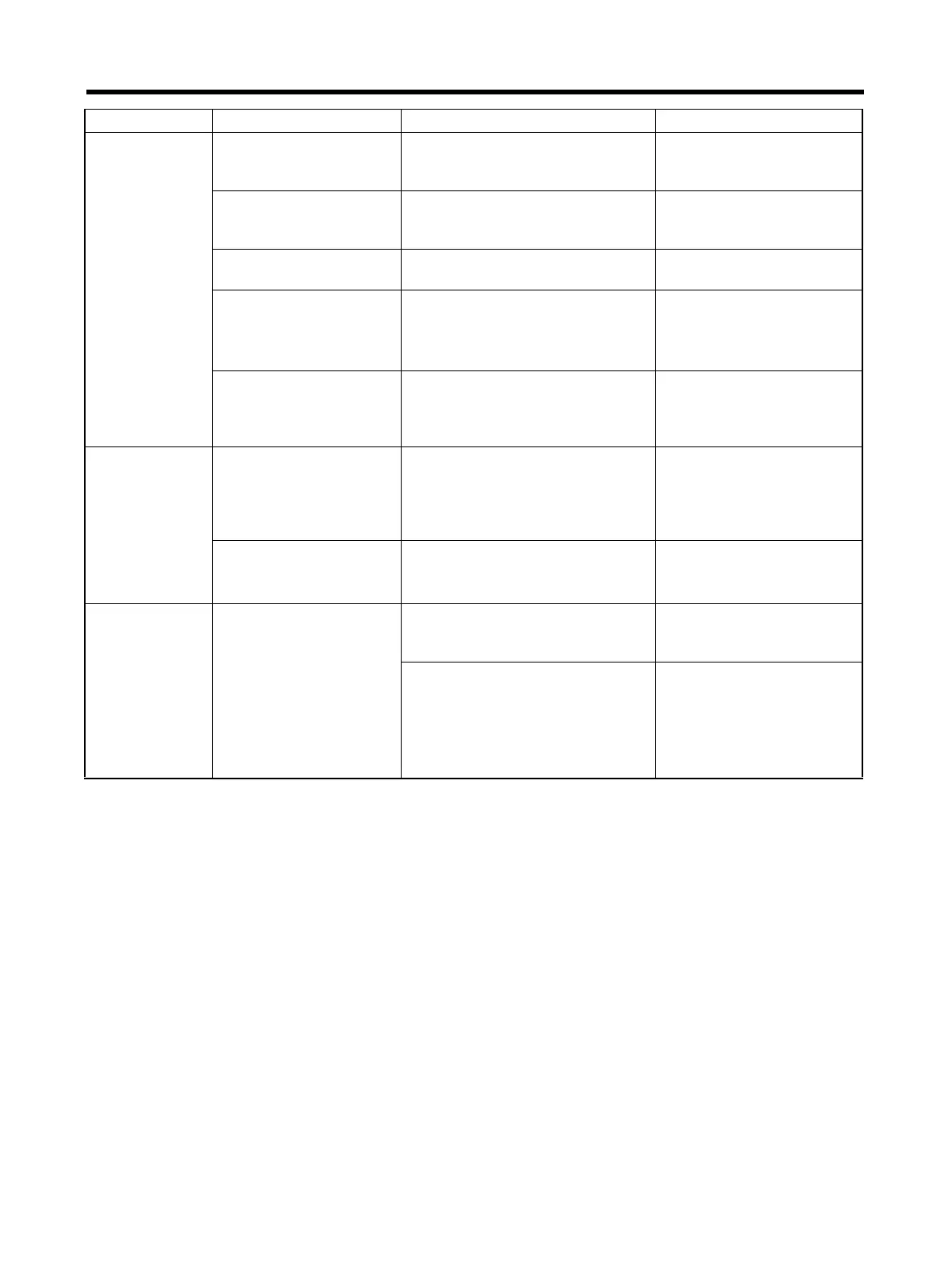

Chapter 5

5-14

Troubleshooting

Servomotor is

overheating.

The ambient temperature

is too high.

Check to be sure that the ambient

temperature around the Servomo-

tor is no higher than 40

°C.

Lower the ambient temper-

ature to 40

°C or less. (Use

a cooler or fan.)

Servomotor installation

area temperature is too

high.

Check to be sure that the Servo-

motor installation area tempera-

ture is no higher than 40

°C.

Lower the Servomotor

installation area tempera-

ture.

Ventilation is obstructed. Check to see whether anything is

blocking ventilation.

Ensure adequate ventila-

tion.

There is an overload. Check the torque command value

by means of monitor mode

(Un002).

Lighten the load.

Change to a larger capacity

Servomotor and Servo

Driver.

The correspondence

between the Servo Driver

and the Servomotor is

incorrect.

Check the models. Combine models that corre-

spond correctly.

There are

unusual noises.

The machinery is vibrat-

ing.

Inspect the machinery to see

whether there are any foreign

objects in the movable parts, or

whether there is any damage,

deformation, or looseness.

Fix any problems causing

vibration.

Pn100 (speed loop gain)

is insufficient.

--- Use online autotuning.

Adjust the gain manually

(speed loop gain).

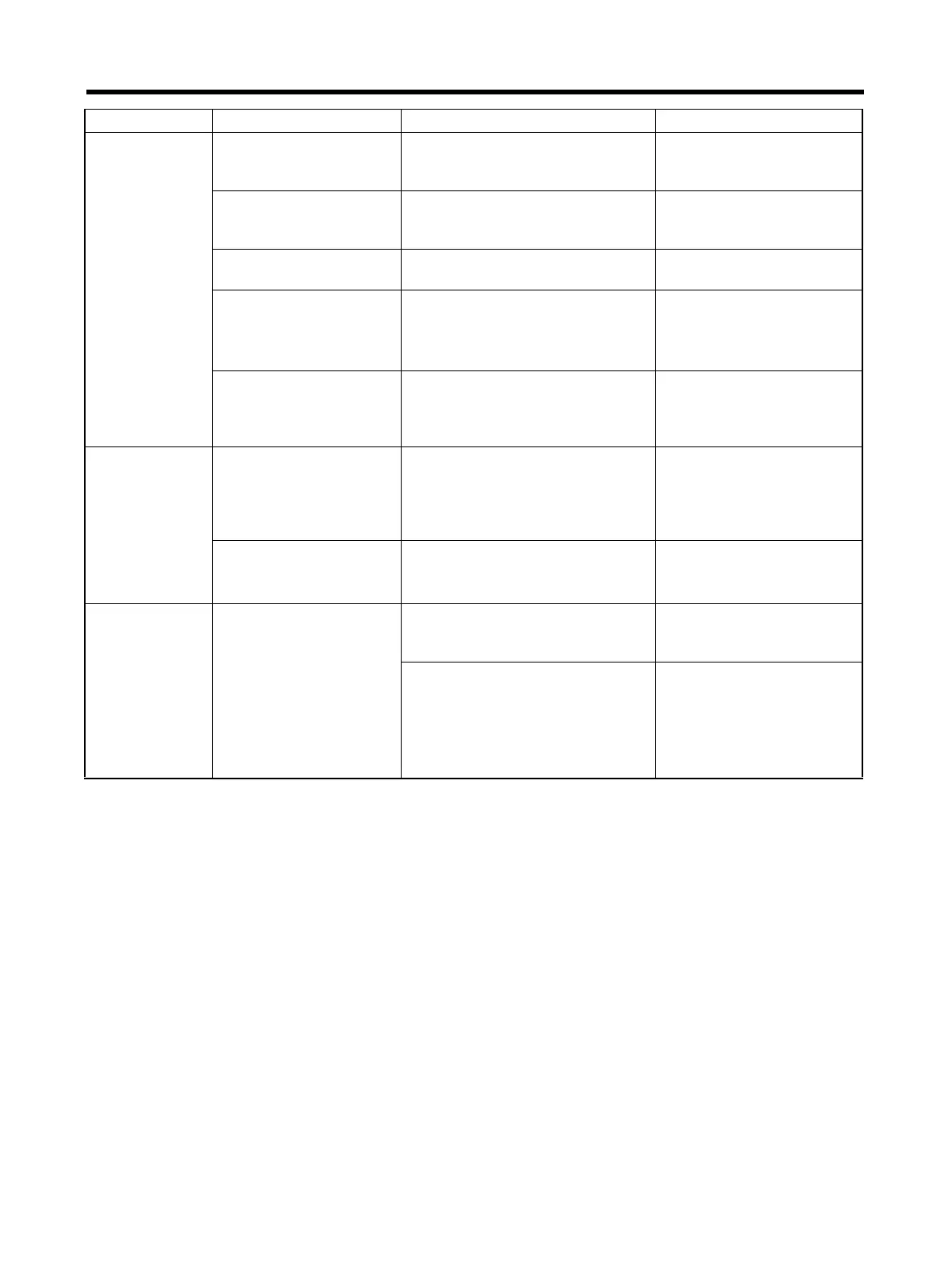

Vibration is

occurring at the

same frequency

as the applica-

ble power sup-

ply.

Inductive noise is occur-

ring.

Check to see whether the Servo

Driver control signal lines are too

long.

Shorten the control signal

lines.

Check to see whether control sig-

nal lines and power supply lines

are too close to each other.

Separate control signal

lines from power supply

lines.

Use a low-impedance

power supply for control

signals.

Symptom Probable cause Items to check Countermeasures

Loading...

Loading...