188

Basic Examples of PID Control Section 5-1

5-1-5 Ramp Program Control

Follow the procedure below to perform program control for changing the Set

Point value in a ramp manner proportionately to the elapsed time.

Function blocks used: Basic PID (Block Model 011)

Ramp Program (Block Model 155)

Step Ladder Program (Block Model 301)

Register the ramp program (max. seven steps, each step comprising a ramp

rate and soak value) in advance to the Step Ladder Program block. The Step

Ladder Program is used in combination with the run/stop command from the

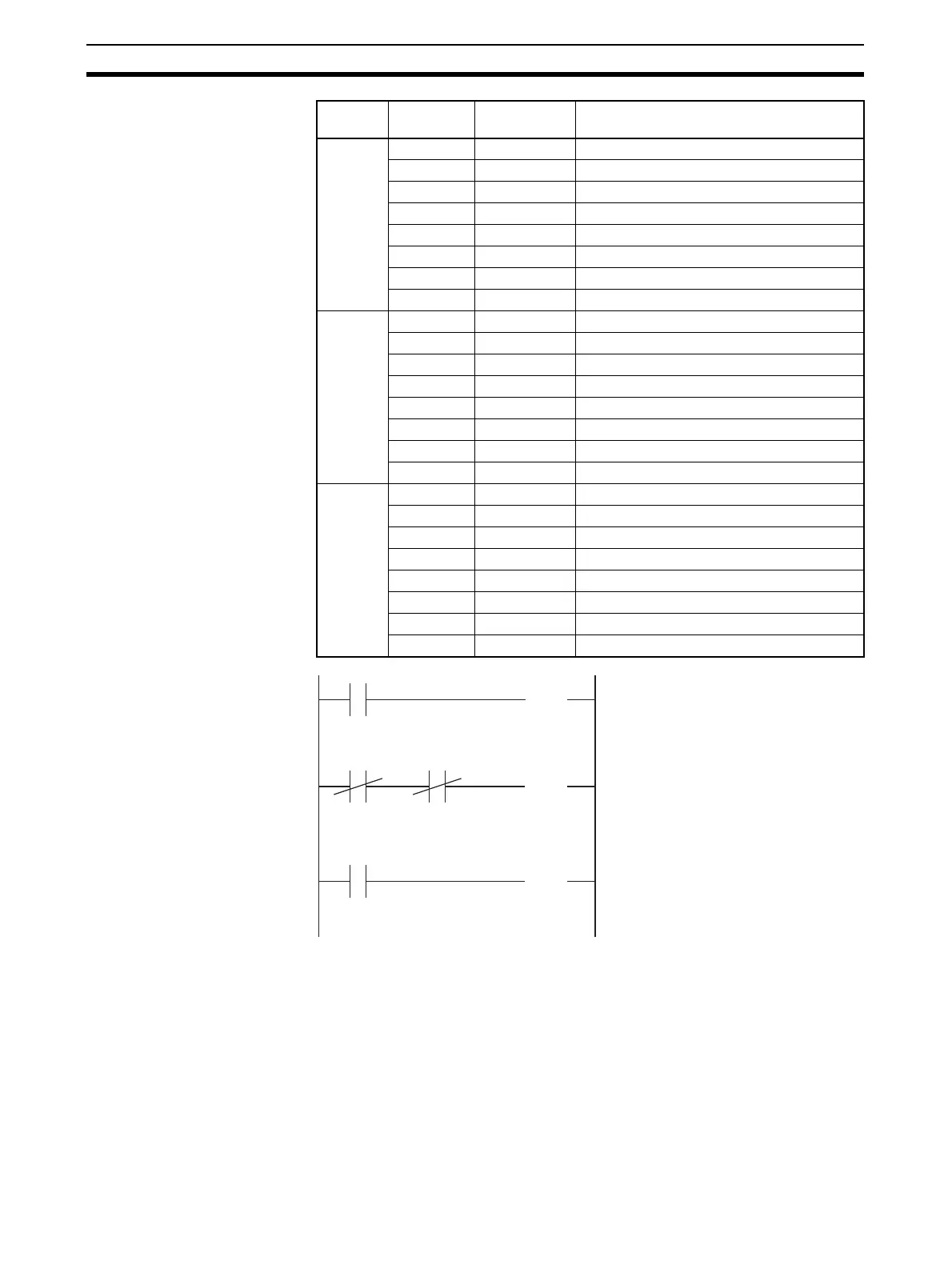

101 002 171 Constant ITEM Setting block

021 Setting of P (proportional band) 1 value

022 Setting of I (integral time) 1 value

023 Setting of D (derivative time) 1 value

011 001054 Destination designation of ITEM021

012 001055 Destination designation of ITEM022

013 001056 Destination designation of ITEM023

039 Batch send switch

102 002 171 Constant ITEM Setting block

021 Setting of P (proportional band) 2 value

022 Setting of I (integral time) 2 value

023 Setting of D (derivative time) 2 value

011 001054 Destination designation of ITEM021

012 001055 Destination designation of ITEM022

013 001056 Destination designation of ITEM023

039 Batch send switch

103 002 171 Constant ITEM setting block

021 Setting of P (proportional band) 3 value

022 Setting of I (integral time) 3 value

023 Setting of D (derivative time) 3 value

011 001054 Destination designation of ITEM021

012 001055 Destination designation of ITEM022

013 001056 Destination designation of ITEM023

039 Batch send switch

Block

address

ITEM No. Data Explanation

(

)

DU

(

)

DU

(

)

DU

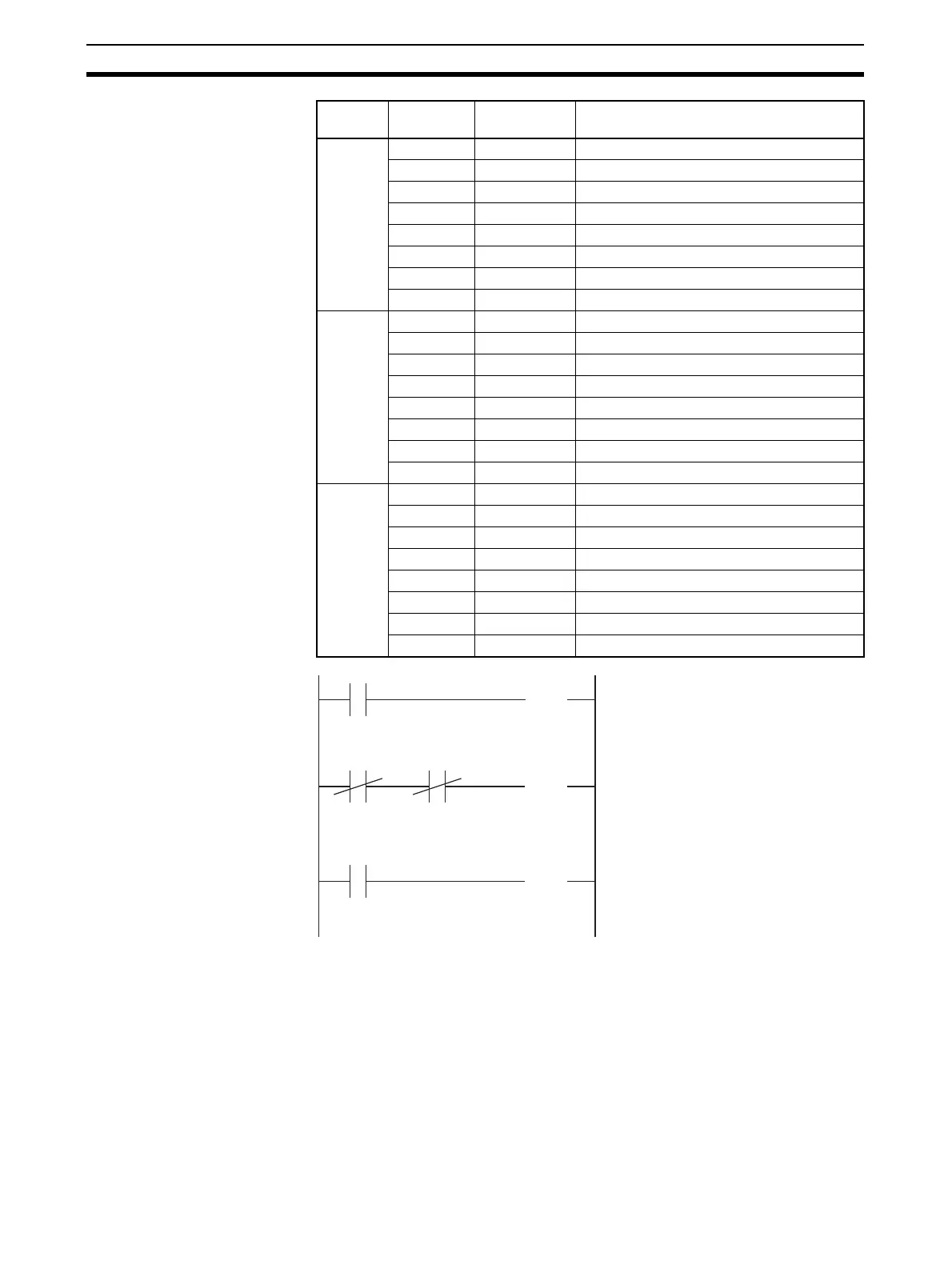

Constant selector 1 at low limit alarm ON

Low limit

alarm

Constant selector 1

Constant selector 2 at high limit alarm OFF and

low limit alarm OFF

High limit

alarm

Constant selector 2

Constant selector 3 at high limit alarm ON

High limit

alarm

Constant selector 3

Low limit

alarm

Loading...

Loading...