66

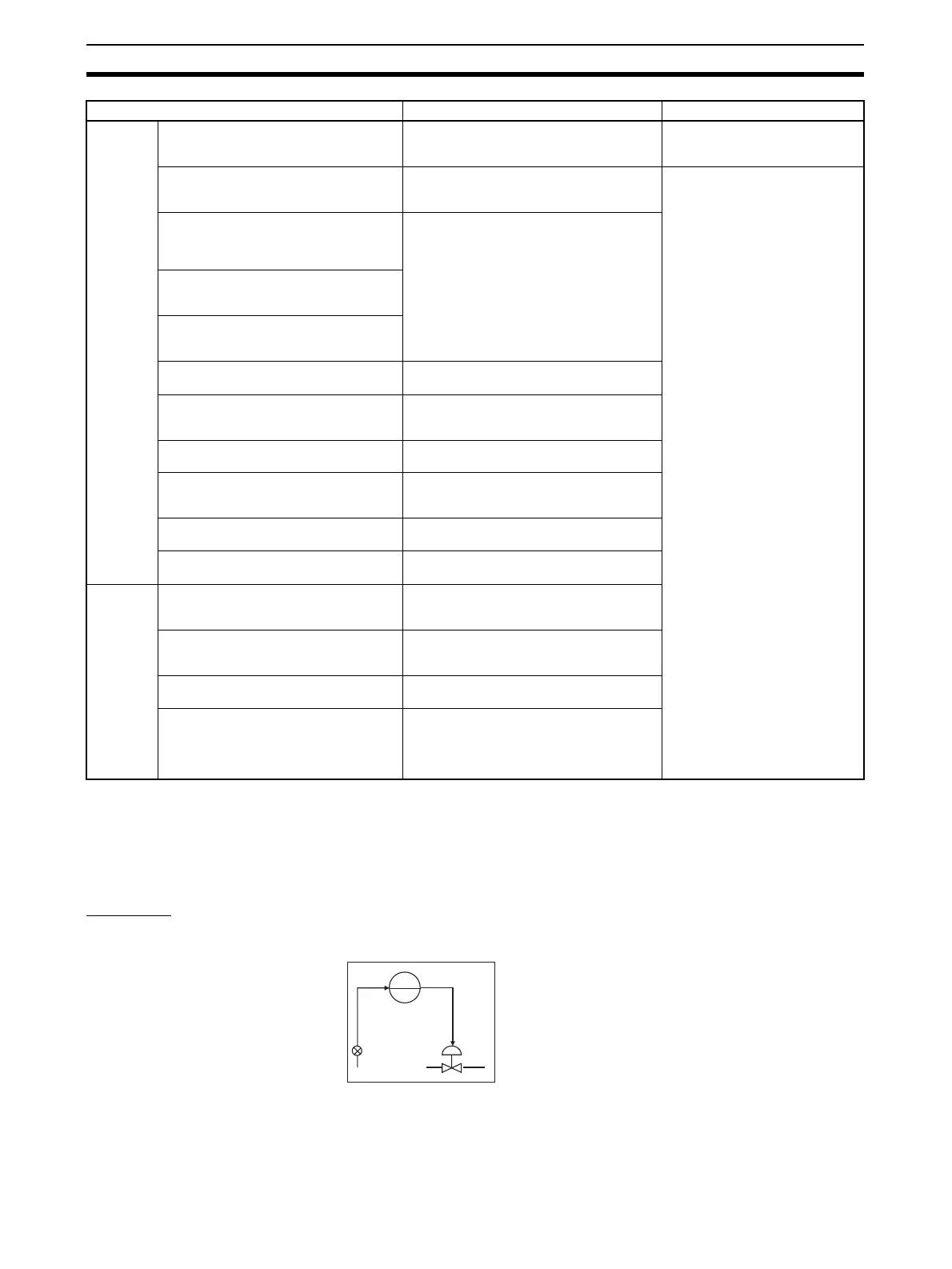

Basic Procedure for Using the Loop Controller Section 1-5

1-5 Basic Procedure for Using the Loop Controller

This section describes the basic procedure for using the Loop Controller.

For examples of actual procedures, see Section 4 Simple Examples of Use.

1. Design

1,2,3... 1. Prepare an instrumentation drawing.

See this Section (for understanding which functions can be used on the

Loop Controller).

See Section 5 Examples of Function Block Combinations.

Analog

signal set-

ting/selec-

tion

Setting of analog signals to specified

ITEMs under certain conditions

Use the Variable ITEM Setting block (Block

Model 171).

3-1 Configuration of Function

Blocks and Function Block Refer-

ence Manual

Selection of one of multiple analog sig-

nals and transmission of that analog sig-

nal as an analog signal

Use the Input Selector block (Block Model

162).

Function Block Reference Manual

Selection of the maximum value from

multiple analog signals and transmission

of that maximum value as an analog sig-

nal

Use the Rank Selector block (Block Model

161).

Selection of the minimum value from mul-

tiple analog signals and transmission of

that minimum value as an analog signal

Selection of the nth largest value from

multiple analog signals and transmission

of the signal as an analog signal

Switching of sensors on a different mea-

suring system or measurement target

Use the 3-input Selector block (Block Model

163).

Switching of operation nodes on a differ-

ent measuring system or measurement

target

Use the 3-output Selector block (Block

Model 164).

Changing two settings with a ramp (e.g.,

opening and closing valves)

Use the Ramped Switch block (Model Block

167).

Converting ranges of analog signals

merely by setting values for 0% and

100% inputs and 0% and 100% outputs

Use the Range Conversion block (Block

Model 127).

Comparison of constant and analog sig-

nals

Use the Constant Comparator block (Block

Model 202).

Comparison of two analog signals Use the Variable Comparator block (Block

Model 203).

Manipula-

tion/moni-

tor/control

of special

external

control tar-

get

Manipulation and monitoring of ON/OFF

valve with open/close limit switches

Use the ON/OFF Valve Manipulator block

(Block Model 221) and Switch Meter block

(Block Model 225).

Manipulation and monitoring of motors Use the Motor Manipulator block (Block

Model 222) and Switch Meter block (Block

Model 225).

Manipulation and monitoring of reversible

motors

Use the Reversible Motor Manipulator block

(Block Model 223).

Manipulation of a electric positional-pro-

portional motor as the control target

Use the Basic PID (Block Model 011)/

Advanced PID block (Block Model 012) and

Motor Opening Manipulator block (Block

Model 224) and Switch Meter block (Block

Model 225).

To perform this specific operation Perform the following See page:

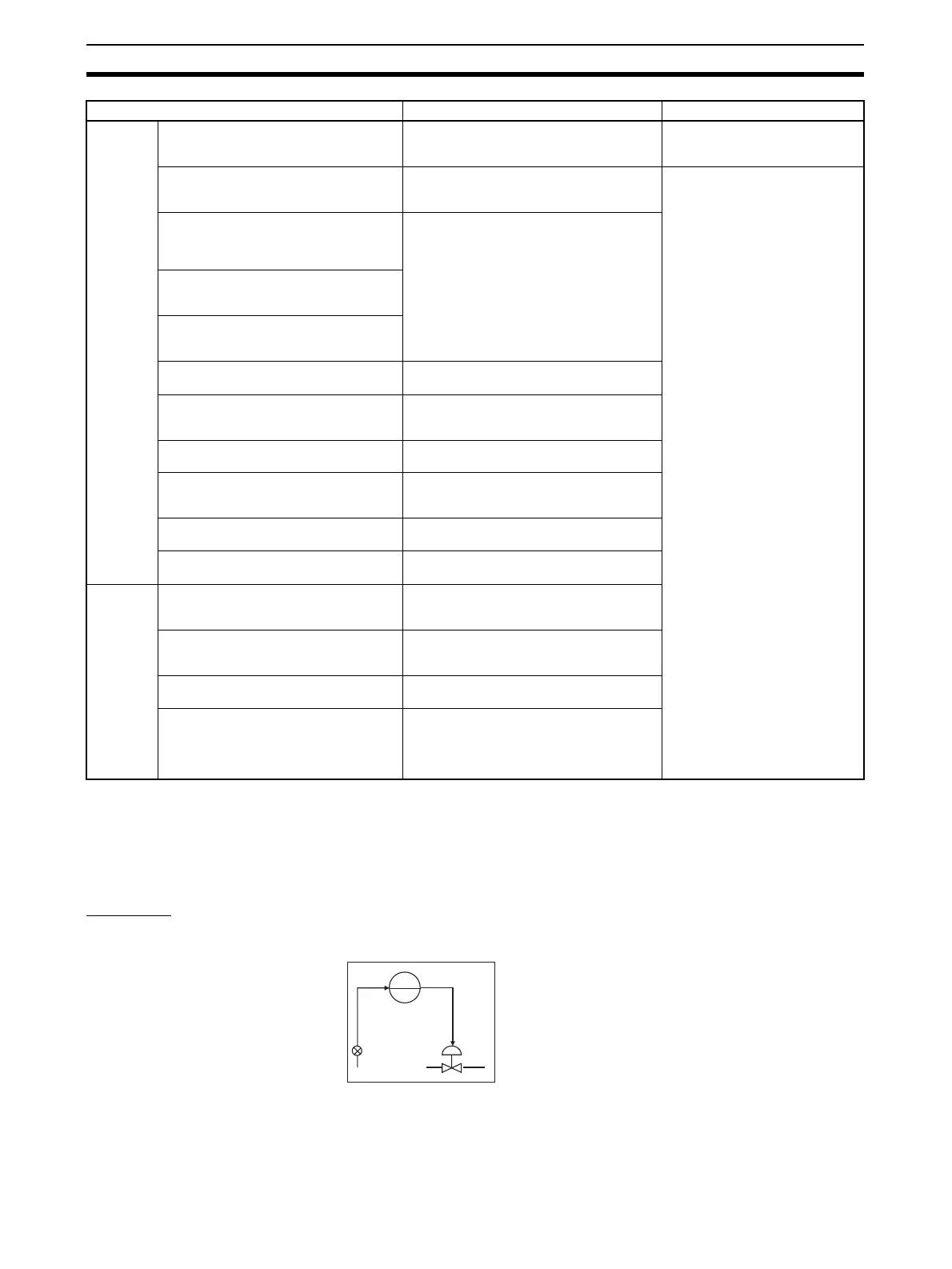

PIDPV MV

Loading...

Loading...