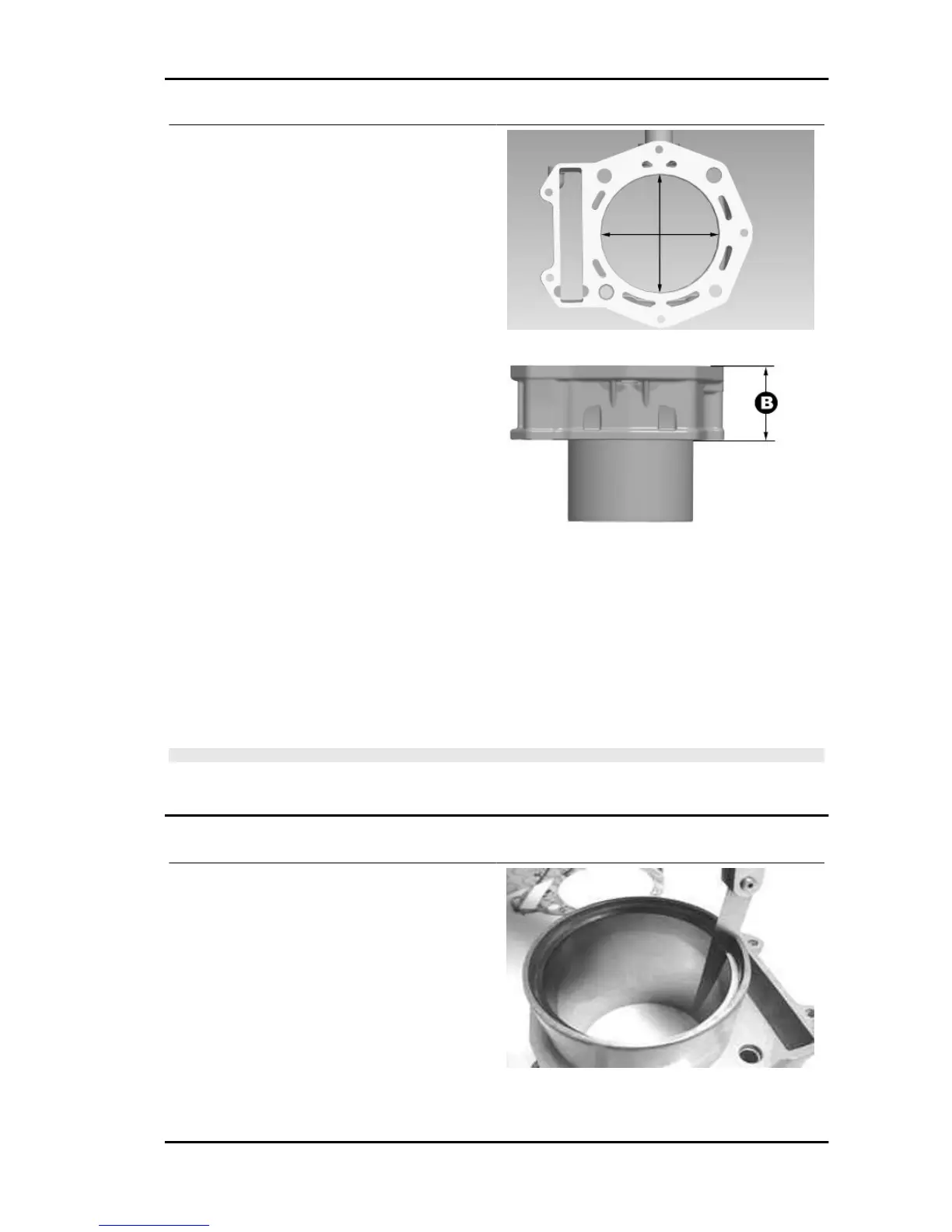

- Using a bore meter, measure the cylinder inner

diameter at a given height according to the direc-

tions shown in the figure.

Characteristic

B:

43 mm

Standard diameter:

94 mm nominal value

- Check that coating is free from flakes.

- Check that the coupling surface with the head is not worn or misshapen.

Characteristic

Maximum run-out allowed:

0.001 in 0.05 mm

- Pistons and cylinders are classified into categories based on their diameter. The coupling is carried

out in pairs (A-A, B-B, C-C, D-D).

N.B.

REFER TO THE «SPECIFICATIONS» SECTION FOR THE SIZES OF THE CYLINDER AND THE

CYLINDER-PISTON COUPLING CLEARANCES.

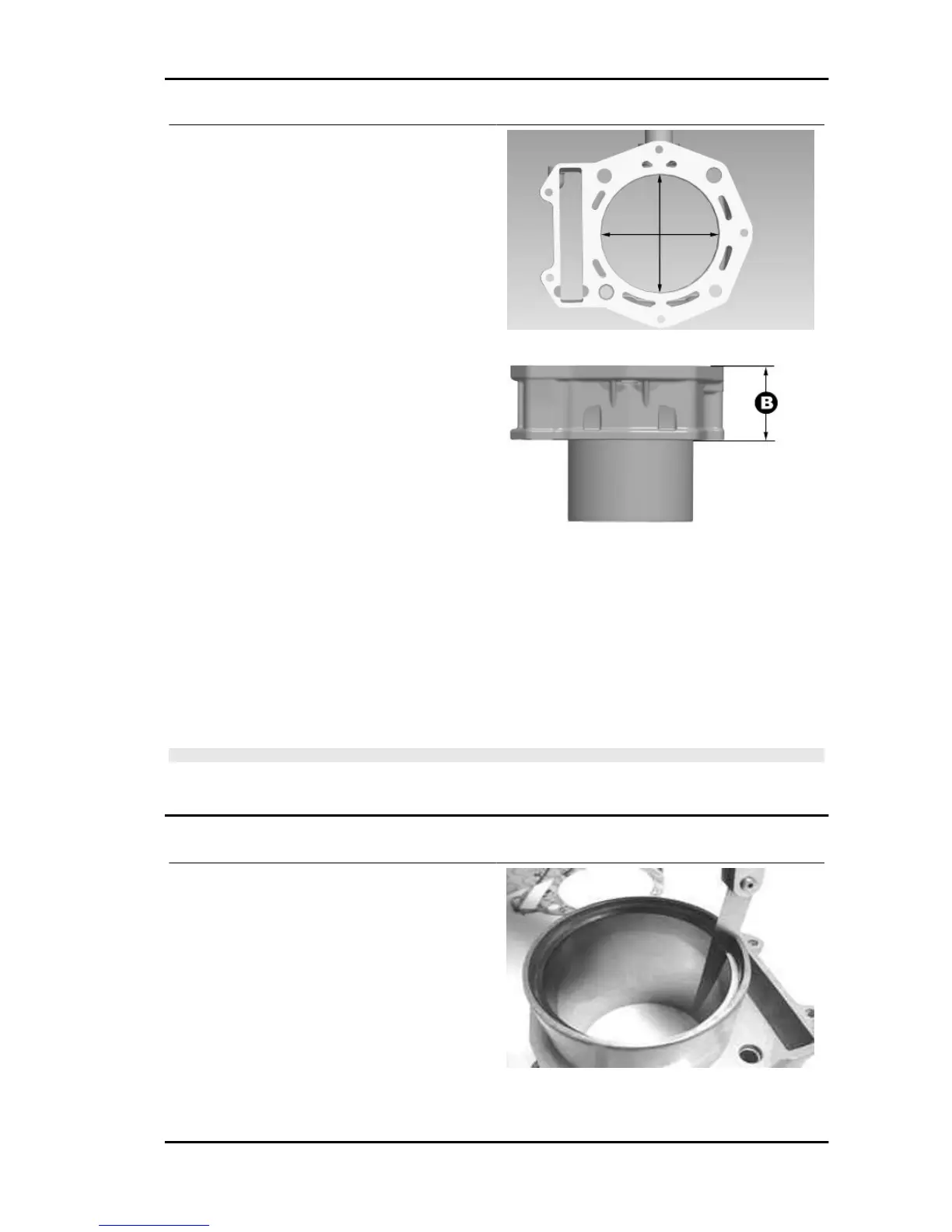

Inspecting the piston rings

- Alternately insert the three sealing rings into the

cylinder, in the area where it retains its original di-

ameter. Using the piston, insert the rings perpen-

dicularly to the cylinder axis.

- Make sure that each single sealing ring evenly

adheres to the cylinder liner. If it does not, this

means the ring is worn. Replace it.

- Measure the opening (see figure) of the sealing

rings using a feeler gauge.

MP3 500 i.e. SPORT Business_LT_ ABS-ASR_EU_USA (2015) Engine

ENG - 199

Loading...

Loading...