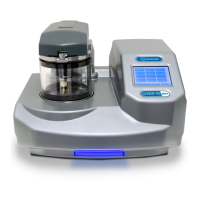

Q150T Sample Preparation System

Q150T - Instruction Manual 3 10473 - Issue 5

Contents

Section Contents

1 Introduction.......................................................................................................... 8

1.1 General Description .........................................................................................8

1.2 Sputter Coating................................................................................................9

1.3 Carbon Coating................................................................................................9

1.4 Metal Evaporation ............................................................................................9

1.5 Aperture Cleaning ............................................................................................9

2 Installation.......................................................................................................... 10

2.1 Pre-installation............................................................................................... 10

2.1.1 Required Services .......................................................................................................10

2.2 Unpacking...................................................................................................... 11

2.3 Connections................................................................................................... 12

2.3.1 Gas Connections ........................................................................................................13

2.3.2 Electrical Connections.................................................................................................14

2.3.3 Aux Network Connection .............................................................................................14

2.3.4 Vacuum Connections ..................................................................................................15

2.3.5 Fitting the Standard Stage........................................................................................... 16

2.3.6 Optional Connections ..................................................................................................16

3 Operation............................................................................................................ 17

3.1 Switching On for the First Time ...................................................................... 17

3.1.1 The Standby screen ....................................................................................................17

3.2 Running a Profile ...........................................................................................18

3.3 System Settings............................................................................................. 20

4 Working with Profiles......................................................................................... 21

4.1 Editing the Active Profile ................................................................................ 21

4.2 Profile Editor .................................................................................................. 21

4.2.1 Creating a New Profile ................................................................................................23

4.2.2 Editing Profile Parameters...........................................................................................24

4.3 Materials........................................................................................................ 25

4.3.1 Creating a New Material ..............................................................................................26

4.3.2 Editing Material Parameters ........................................................................................26

4.3.3 Deleting a Material.......................................................................................................27

5 Application Guidelines ...................................................................................... 28

5.1 QT Timed Sputter .......................................................................................... 28

5.1.1 Tungsten SEM work....................................................................................................28

5.1.2 High resolution SEM coatings for field emission SEM ................................................28

5.1.3 Aluminium thin film......................................................................................................29

5.2 QT FTM Terminated Sputter........................................................................... 30

5.2.1 High resolution SEM coatings for field emission SEM ................................................30

5.2.2 General thin film coatings............................................................................................30

5.3 Metal Evaporation .......................................................................................... 31

5.3.1 How to achieve a 20nm gold coating ...........................................................................31

5.4 Pulsed Cord Evaporation................................................................................ 32

5.4.1 How to create a 20nm carbon coating .........................................................................32

5.5 Controlled Pulse Cord Evaporation................................................................. 32

5.5.1 Using Controlled Pulse to create a 15nm coat or 2-3nm for EBSD.............................32

5.6 Pulsed Rod Evaporation................................................................................. 34

5.6.1 How to create a conductive layer for SEM................................................................... 34

5.7 Ramped Profile .............................................................................................. 35

5.7.1 Carbon insert setup.....................................................................................................35

5.7.2 The ramped current profile..........................................................................................36

5.7.3 Adjusting coating thickness.........................................................................................37

5.7.4 How to create a carbon support layer For TEM........................................................... 37

How to create a conductive carbon layer for SEM ....................................................................38

5.8 Using Outgas Source options......................................................................... 39

5.8.1 Setting Outgas Source options ................................................................................... 39

5.8.2 Running Multiple Outgassing ......................................................................................39

5.9 Glow Discharge..............................................................................................40

5.9.1 Hydrophilisation...........................................................................................................40

5.9.2 Surface Cleaning.........................................................................................................40

Loading...

Loading...