Q150T Sample Preparation System

10473 - Issue 5 38 Q150T - Instruction Manual

How to create a conductive carbon layer for SEM

1. Install the carbon insert as described on page 56. Ensure that the carbon rods are

prepared correctly as described on page 57.

2. Ensure the stage is fitted with the longer support shaft adjusted to a height of

75mm above the base plate.

3. Ensure the extended height cylinder 10429 is fitted as described on page 69.

4. Create a new profile based on QT Ramped Carbon.

5. Edit the newly created profile setting the parameters as shown in Table 9.

6. Run the new profile.

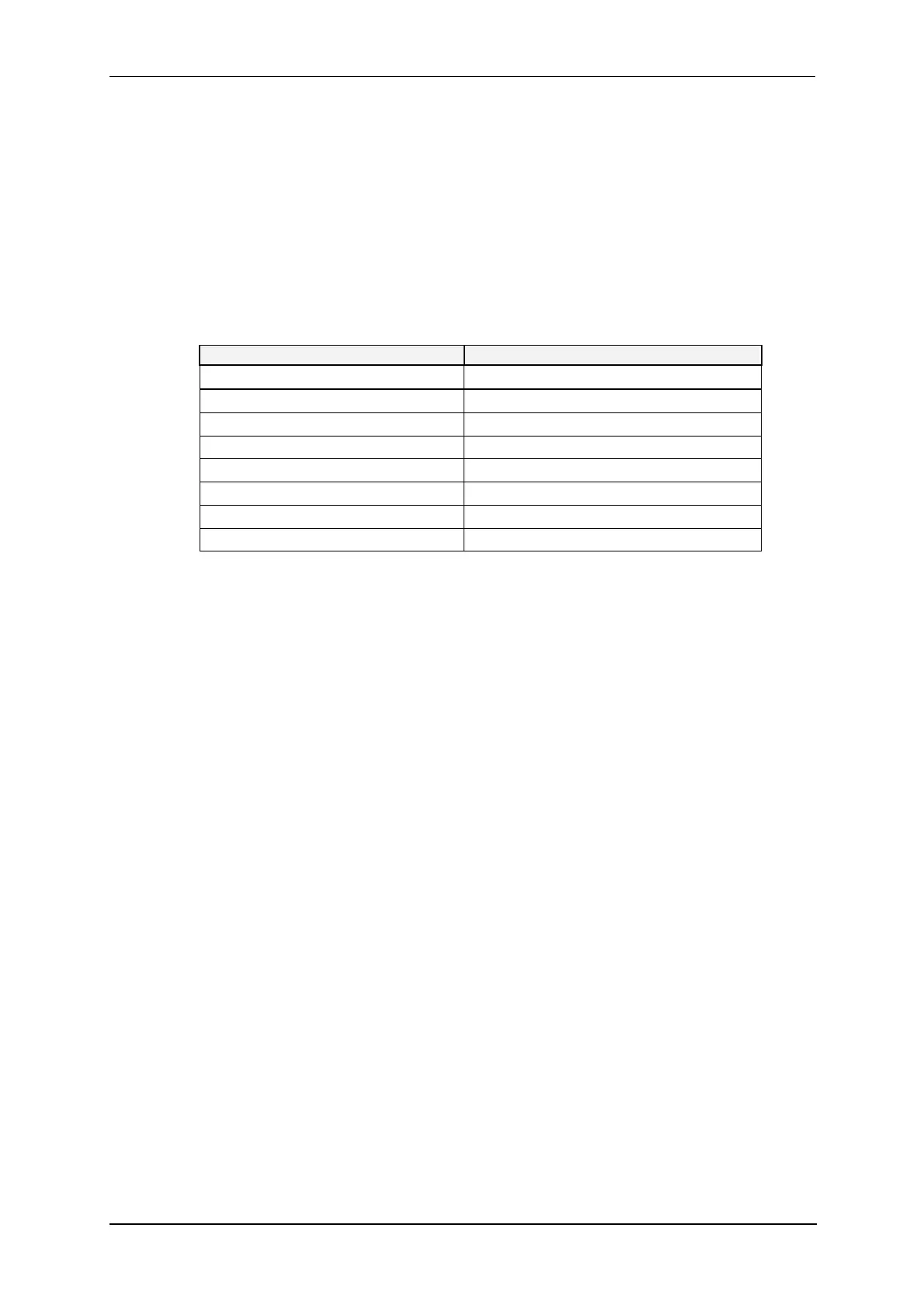

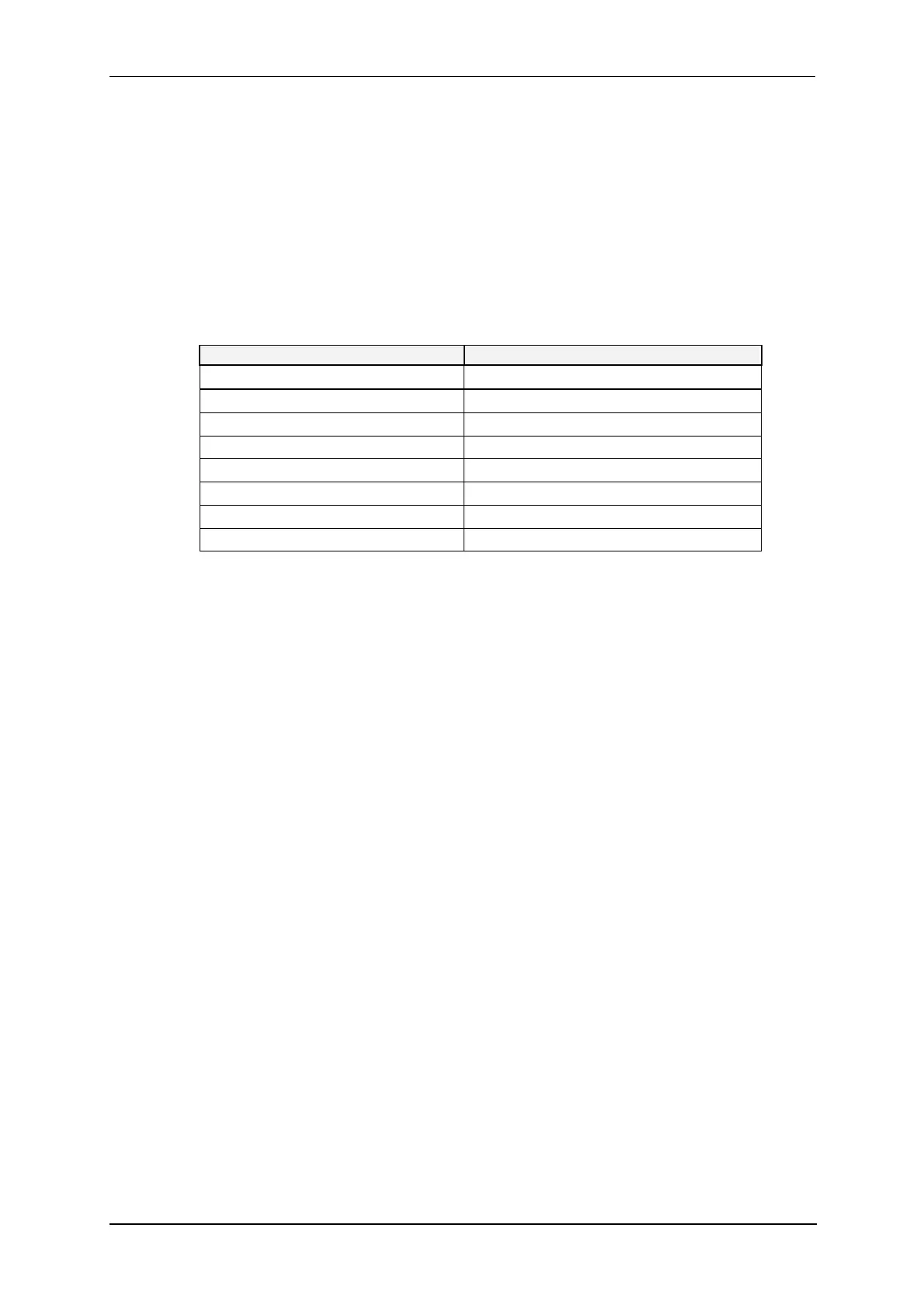

Table 9 QT Ramped Carbon parameters for SEM coatings

Parameter Value

Material Carbon

Evaporation Current 52A

Evaporation Time 1.8 minutes

Current ramp rate 0.25A/S

Out Gas Time 10 seconds

Out Gas Current 20A

Pre Evap End Current 32

Pre Evap Rate 1.00 A/S

Loading...

Loading...