Chapter 5 FactoryTalk Batch View introduction

74

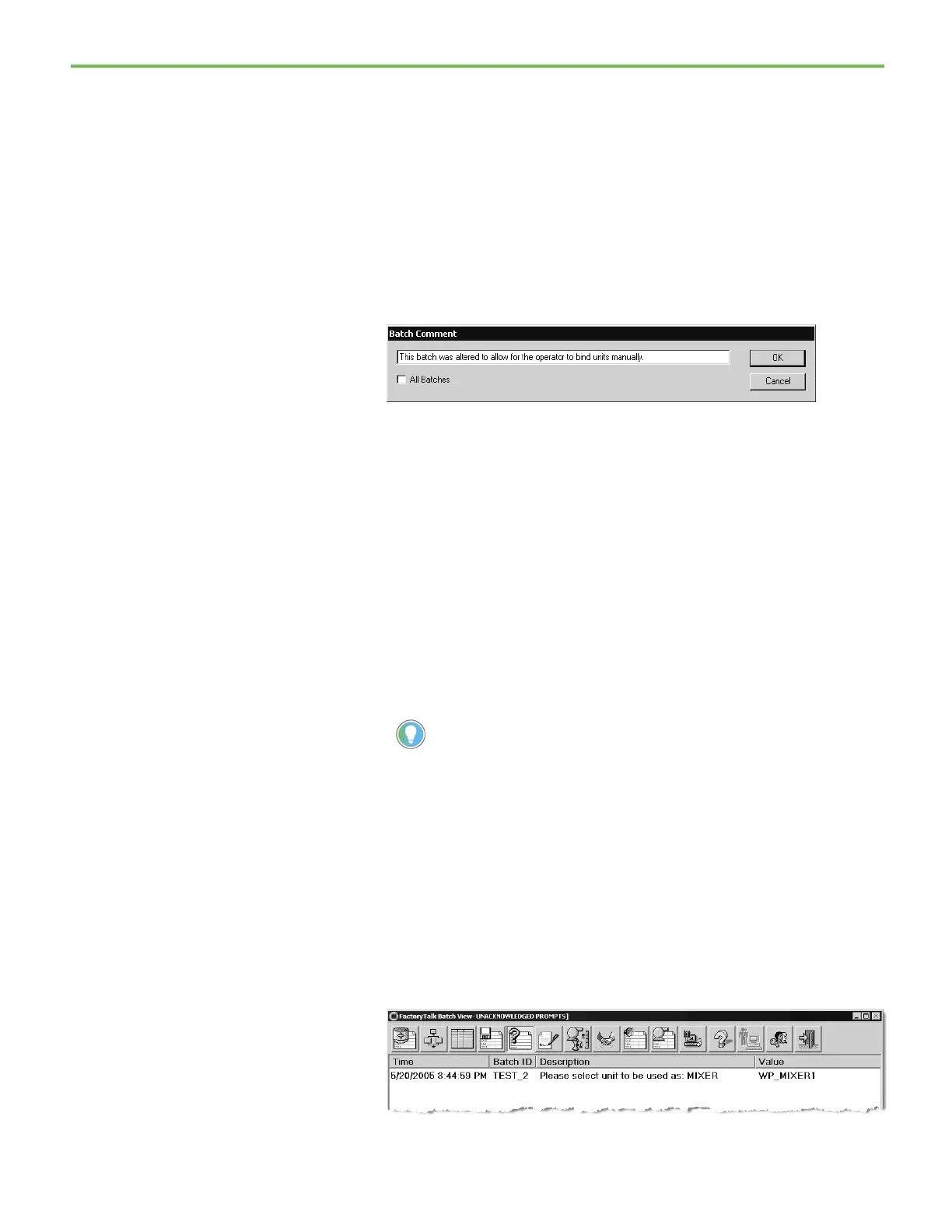

Before you run the batch, you add a comment to add to the Batch Event

Journal.

To add a comment to a sample batch:

1. Select the Batch List button to return to the Batch List view.

2. Select the TEST_2 batch, and then select the Comment command

button. The Batch Comment dialog box opens.

3. Type This batch was altered to allow the operator to bind units

manually.

4. Select OK to return to the Batch List window.

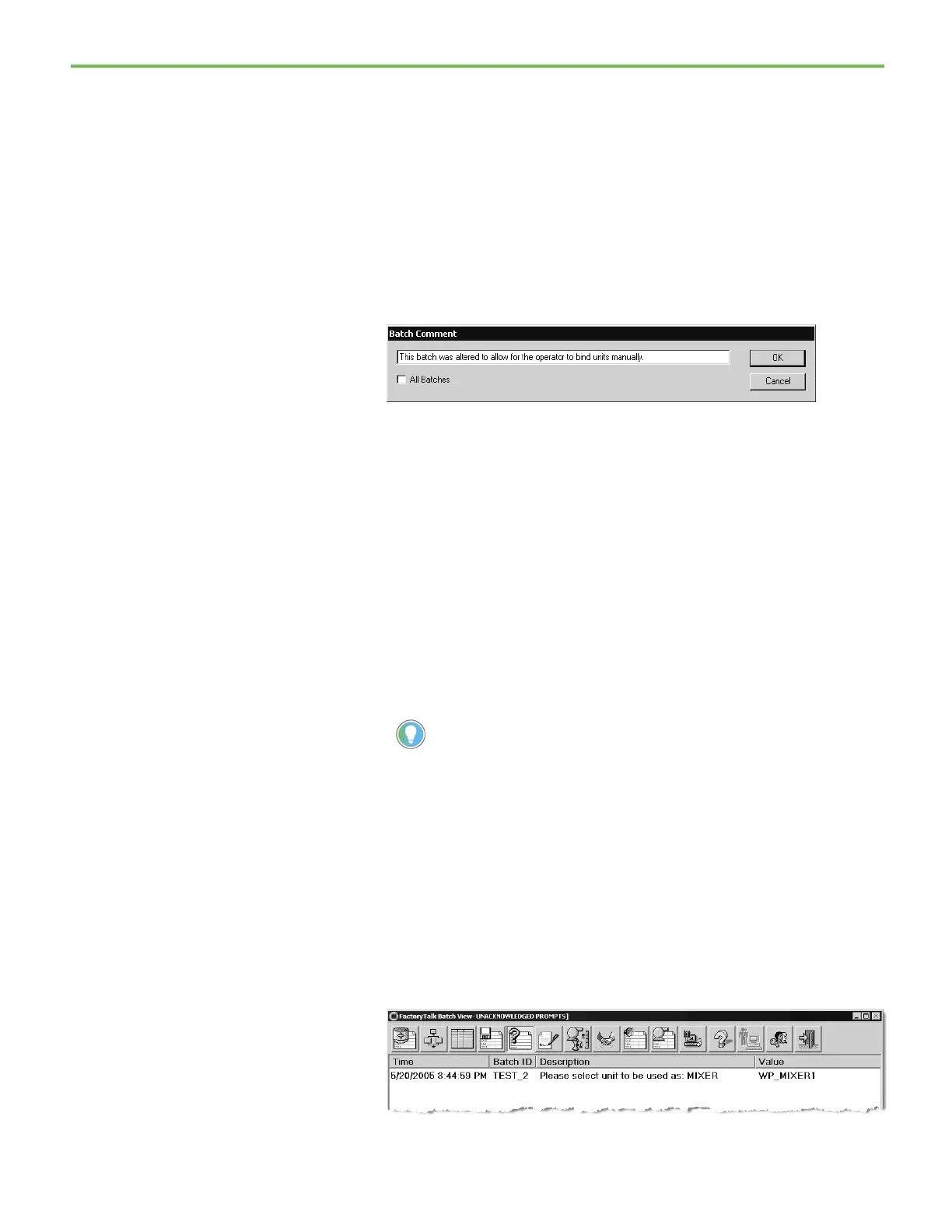

Because you selected Prompt binding, the batch stops running when binding

is to occur and you must use the Unacknowledged Prompts list to select the

units to bind.

To respond to unacknowledged sample prompts:

1. Select the Start Batch command button, and then select Yes to start

the batch.

Tip: If the Command Signature dialog box opens, refer to Run a sample batch for

instructions.

The Unacknowledged Prompts button begins to flash yellow. You

could address this request from the Batch List view but switch to the

SFC view to see how the binding changes.

2. Select the Procedure as SFC button. Notice that the first transition

indicates BINDING, which means the FactoryTalk Batch Server is

trying to acquire an equipment phase to run the CLS_SWEETCREAM

unit procedure.

3. Select the flashing Unacknowledged Prompts button. The

Unacknowledged Prompts List opens indicating that the operator

must select the unit to use as the MIXER.

Add a comment to a sample

batch

unacknowledged sample

prompts

Loading...

Loading...