BRP-Rotax

MAINTENANCE MANUAL LINE

LEAKAGE CHECK

General note

ATTENTION

Leaking connections can lead to engine problems or engine failure!

Visual inspection of the whole engine for leaks. If leaks are visible, locate the cause and

remedy the fault.

Water pump Checking water pump for leaks

If the leakage bore, located at the base of the ignition housing, is dripping oil, the oil seal

on the water pump shaft may be defective and must be replaced. In the case of coolant

drips at the leakage bore, the coolant mechanical seal must be replaced (inspect the qual-

ity of the coolant).

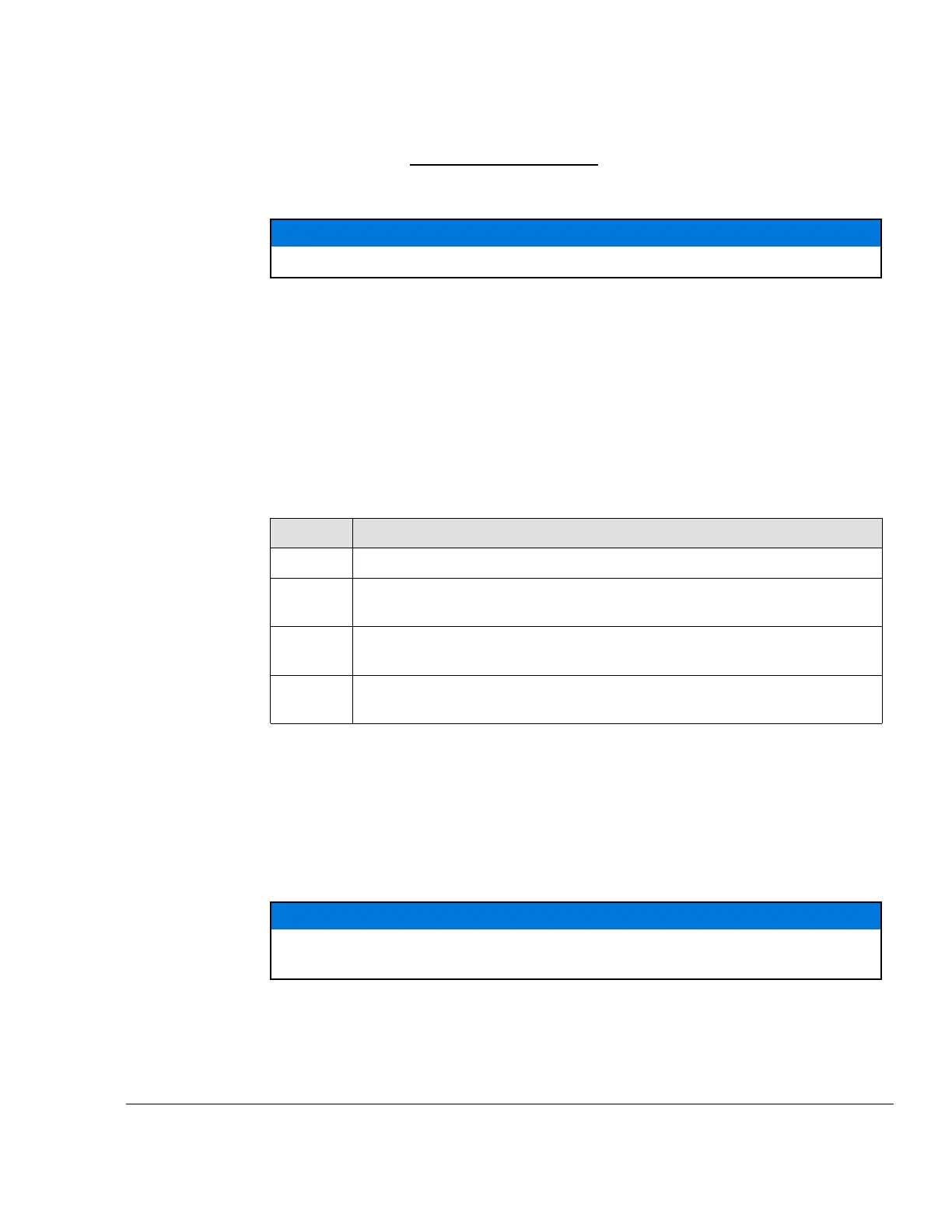

NOTE

If a coolant leak is suspected, the following steps must be taken:

Step

Procedure

1

Clean the engine.

2 Operate the engine until the temperatures have stabilized for a period of 5

min. (engine oil temperature between 50 ° to 70 °C (122 °- 158 °F).

3

Switch “OFF“ ignition and secure engine against unintentional operation.

Secure aircraft against unauthorized operation.

4

For a period of 1 minute after the engine has been stopped, no coolant

must drip down.

Coolant hoses Check coolant hoses and connections and fittings for leakage. Examine the surrounding

area to see if there are any leaks!

Hose clamps,

kinks

Check all hoses, particularly in the area of the hose clamps and hose connections, for po-

rosity, damage and kinks. If damage is detected, replace hose immediately.

Fuel line Inspect fuel line (steel), their connections and screw fasteners. Look for scuffing marks or

other damage.

ATTENTION

Avoid overstretching the fixing elements. Always comply with the specified

torque!

Complete a detailed visual inspection. When checking steel fuel lines (1), pay attention to

the connection areas (2). Look for leaks and cracks.

Effectivity: 912 i Series

Edition 2/Rev. 0

12–20–00

Page 5

September 01/2018

Loading...

Loading...