BRP-Rotax

MAINTENANCE MANUAL LINE

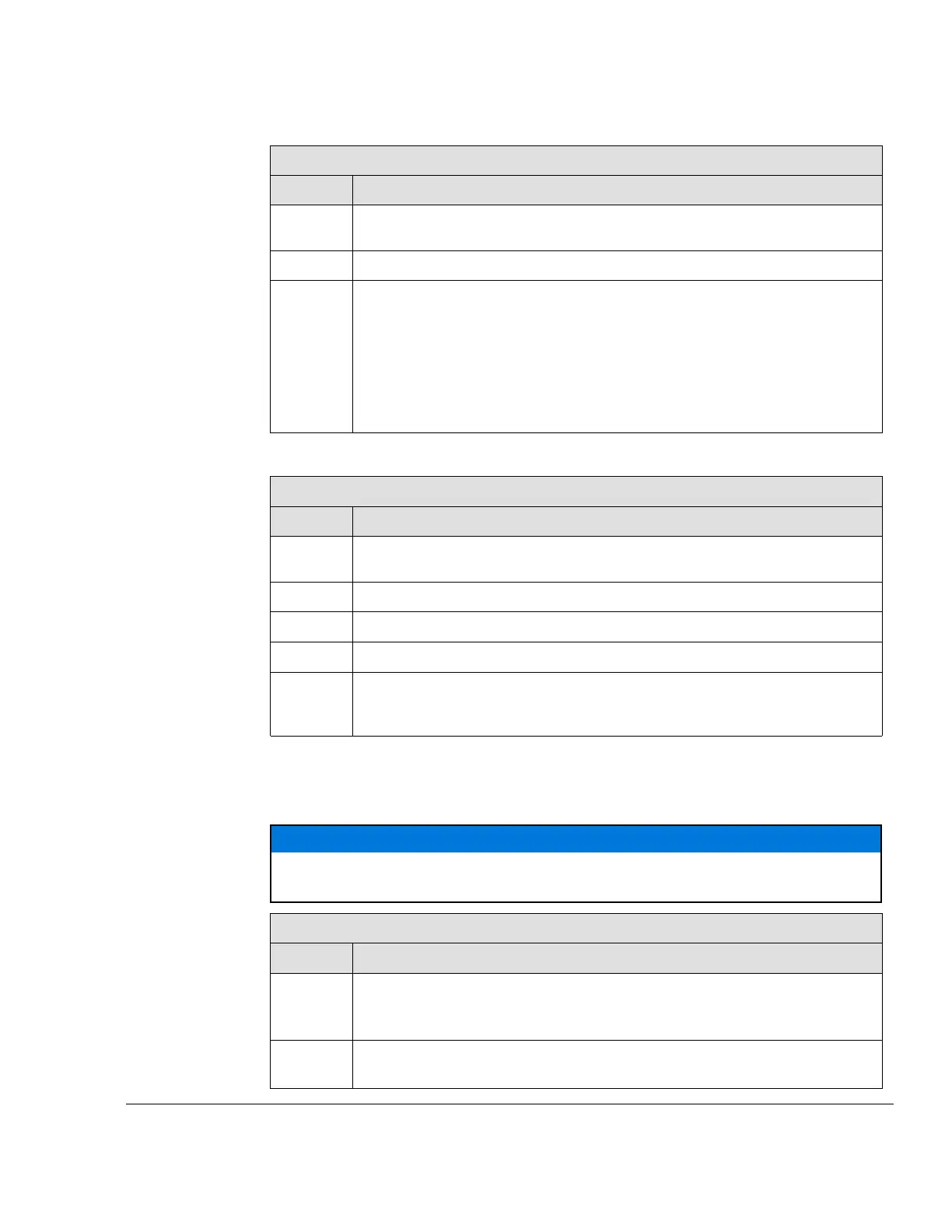

Table 1: Temperature exceeded less than 30 min.

Step

Procedure

1 The whole cooling system must be inspected, repaired or overhauled in ac-

cordance with the BRP-Rotax instructions for continued airworthiness.

2 Inspect all further systems for correct functioning.

3

Carry out detailed inspection of the affected engine components such as:

• Leakage check on the cooling system.

• Check that the cylinder head attachment is fitted securely. If any of the

cylinder head nuts are loose, proceed as instructed in sec. “Excess tem-

perature of over 180 °C (356 °F) and/or for longer than 30 min.“.

• Check all coolant fittings (feed/outflow) for secure fit.

Exceeded for longer than 30 min.

Table 2: Exceeded for longer than 30 min.

Step

Procedure

1 The whole cooling system must be inspected, repaired or overhauled in ac-

cordance with the BRP-Rotax instructions for continued airworthiness.

2

Inspect all further systems for correct functioning.

3

Carry out detailed inspection of the affected engine components.

4

Check compression by carrying out a differential compression check.

5

All cylinder heads and cylinders must be removed and subjected to a de-

tailed check including hardness testing. See chapter 72-00-00 of the Heavy

Maintenance Manual.

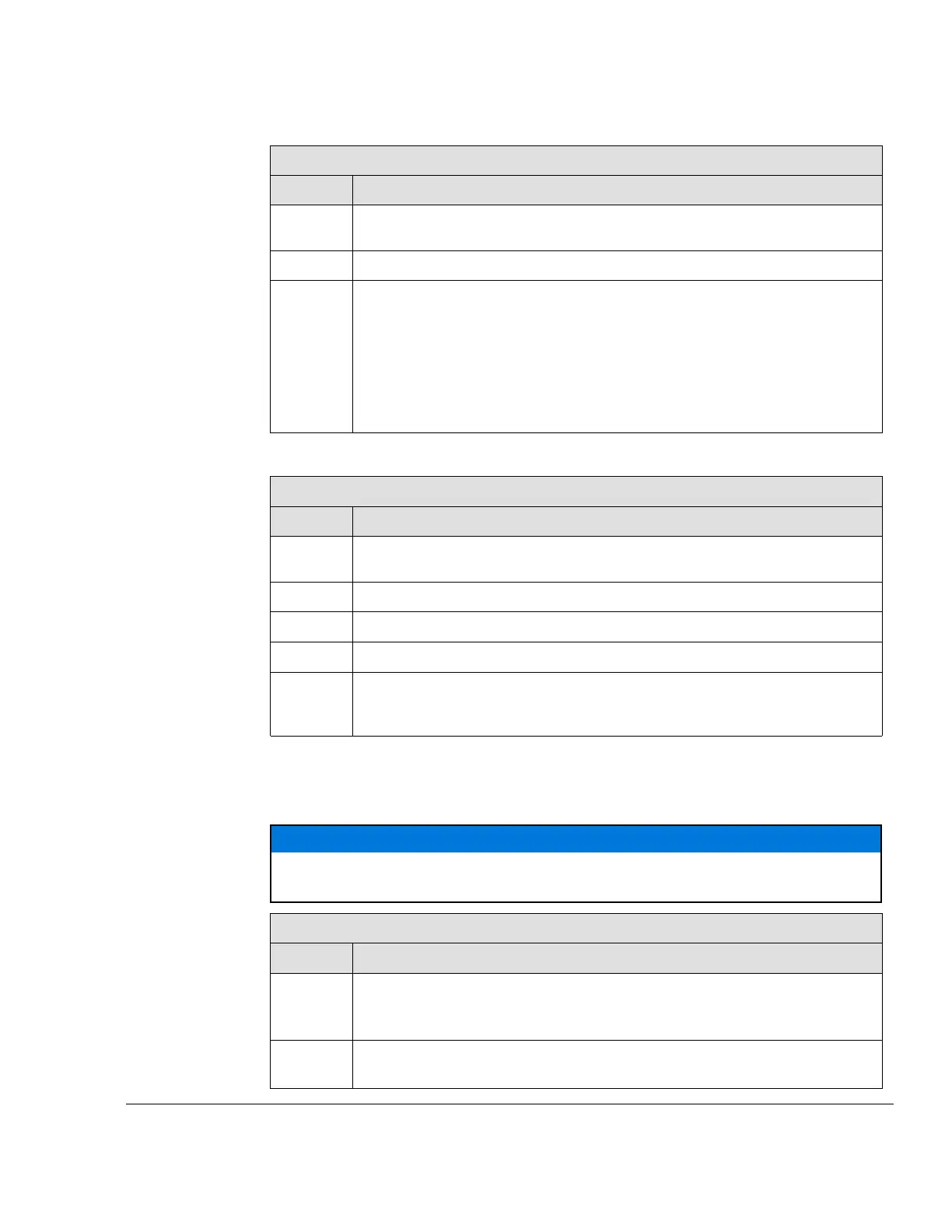

NON COMPLIANCE WITH THE COOLANT SPECIFICATION

General note

ATTENTION

Use only coolant as recommended in the current Operators Manual and SI-912 i-

001 “Selection of suitable operation fluids“, current issue.

Non compliance with the coolant specification

Step

Procedure

1 When a incorrect coolant is used, then the coolant system has to be

flushed.

See Chapter 12-20-00 section Flushing the cooling system.

2

Fill expansion tank with new coolant (highest point of the coolant system).

See Chapter 12-10-00 section Coolant check/replenish.

Effectivity: 912 i Series

Edition 2/Rev. 0

05–50–00

Page 21

September 01/2018

Loading...

Loading...