Hardware Installation and Reference Guide Appendix

88

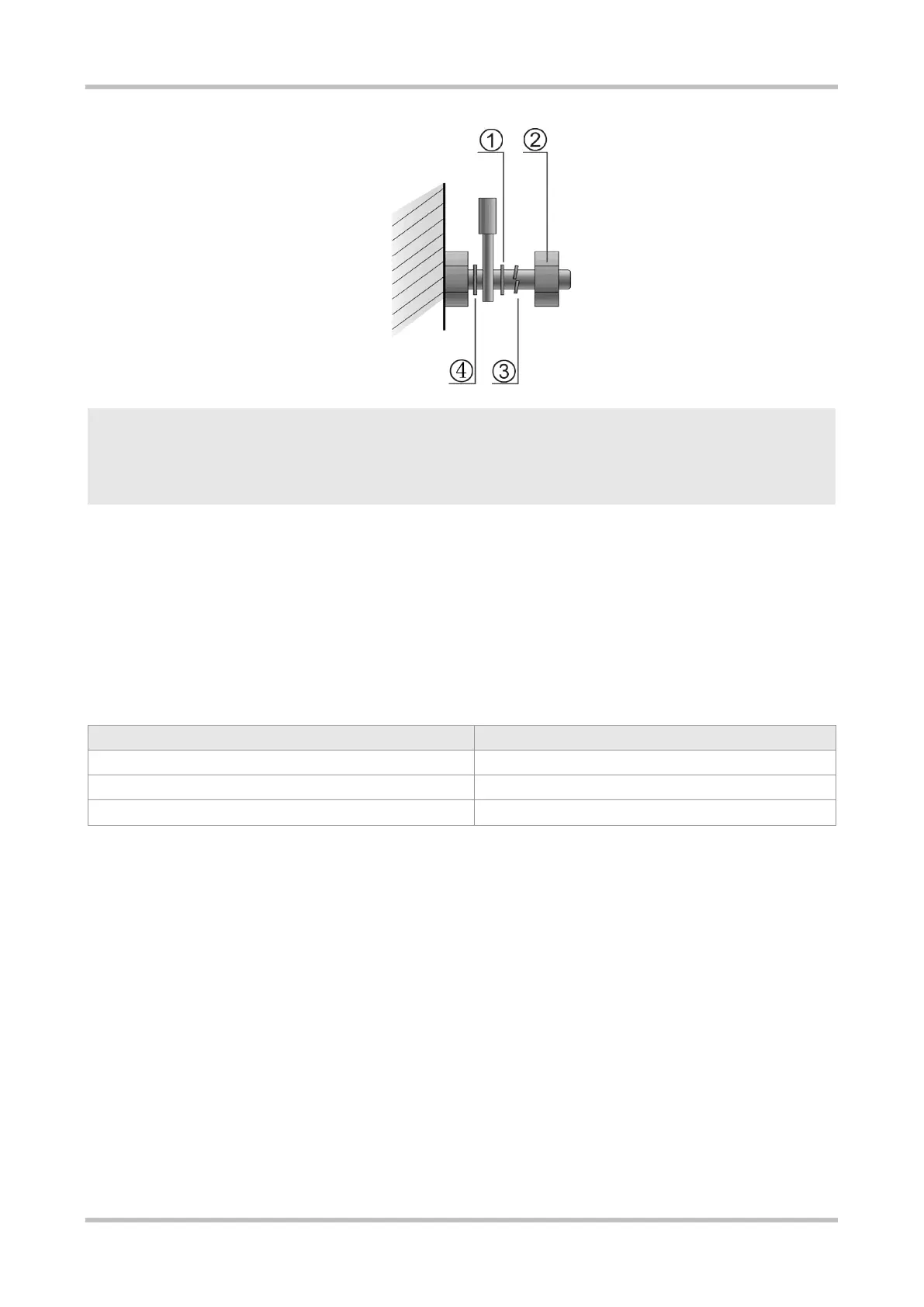

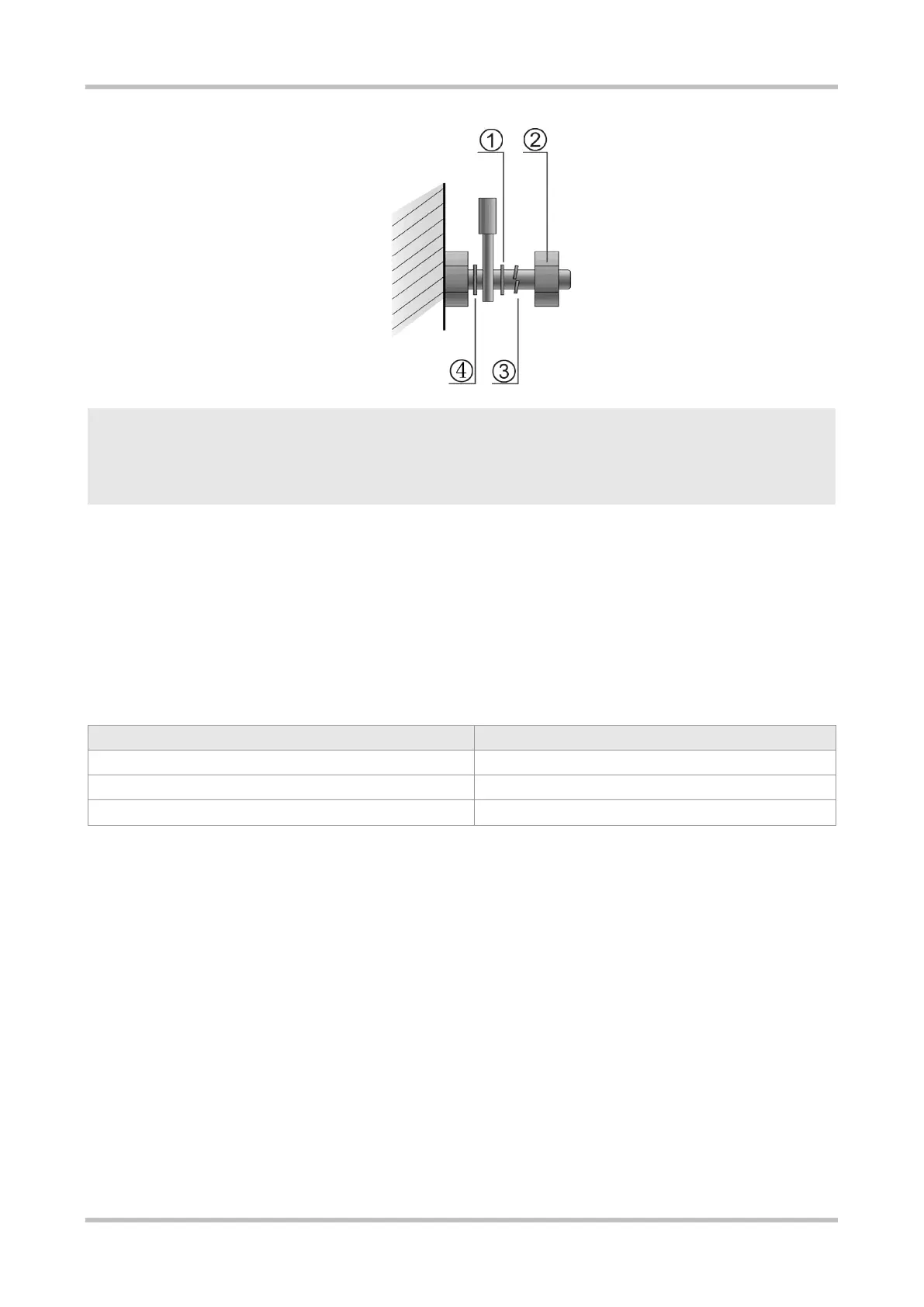

① Flat washer

② Nut

③ Spring washer

④ Flat washer

Hard power cords should be fastened in the terminal connection area to prevent stress on terminal connection and cable.

Do not use self-tapping screws to fasten terminals.

Power cords of the same type and in the same cabling direction should be bundled up into cable bunches, with cables in cable

bunches clean and straight.

Bundle up cables by using cable ties.

Table 7-10 Bundle up Cables Using Cable Ties

Distance between Every Binding Point

80 mm to 150 mm (3.15 in. to 5.91 in.)

10 mm to 30 mm (0.39 in. to 1.18 in.)

150 mm to 200 mm (5.91 in. to 7.87 in.)

200 mm to 300 mm (7.87 in. to 11.81 in.)

No knot is allowed in cabling or bundling.

For wiring terminal blocks (such as circuit breakers) with cord end terminals, the metal part of the cord end terminal should not

be exposed outside the terminal block when assembled.

7.6 Site Selection

The equipment room should be at least 5 km away from heavy pollution sources, such as the smelter works, coal mine, and

thermal power plant. The equipment room should be at least 3.7 km away from medium pollution sources, such as the chemical

factory, rubber factory, and electroplating factory. The equipment room should be at least 2 km away from light pollution sources,

such as the food factory and leather plant. If the pollution source is unavoidable, the machine room should be located on the

windward side of the pollution source perennially with advanced protection.

The equipment room should be at least 3.7 km away from the sea or salt lake. Otherwise, the equipment room must be sealed,

with air conditioner installed for temperature control. Saline soil cannot be used for construction. Otherwise, you should select

devices with advanced protection against severe environment.

Loading...

Loading...