Descriptions of the PLC subroutines

3.22 Subroutine 49 - GearChg1_Auto (automatic spindle gear change)

PLC Subroutines Manual

56 Operating Instructions, 12/2012, 6FC5397-2EP10-0BA0

3.22 Subroutine 49 - GearChg1_Auto (automatic spindle gear change)

Purpose

Subroutine 49 is used to automatically change the gear for the analog spindle with 2-level

gear detection signals.

During a gear change, the spindle oscillates and the PLC outputs the gear change signal.

When the PLC detects that the desired gear level has been reached, the gear change has

been completed.

You cannot use this subroutine together with subroutine 50.

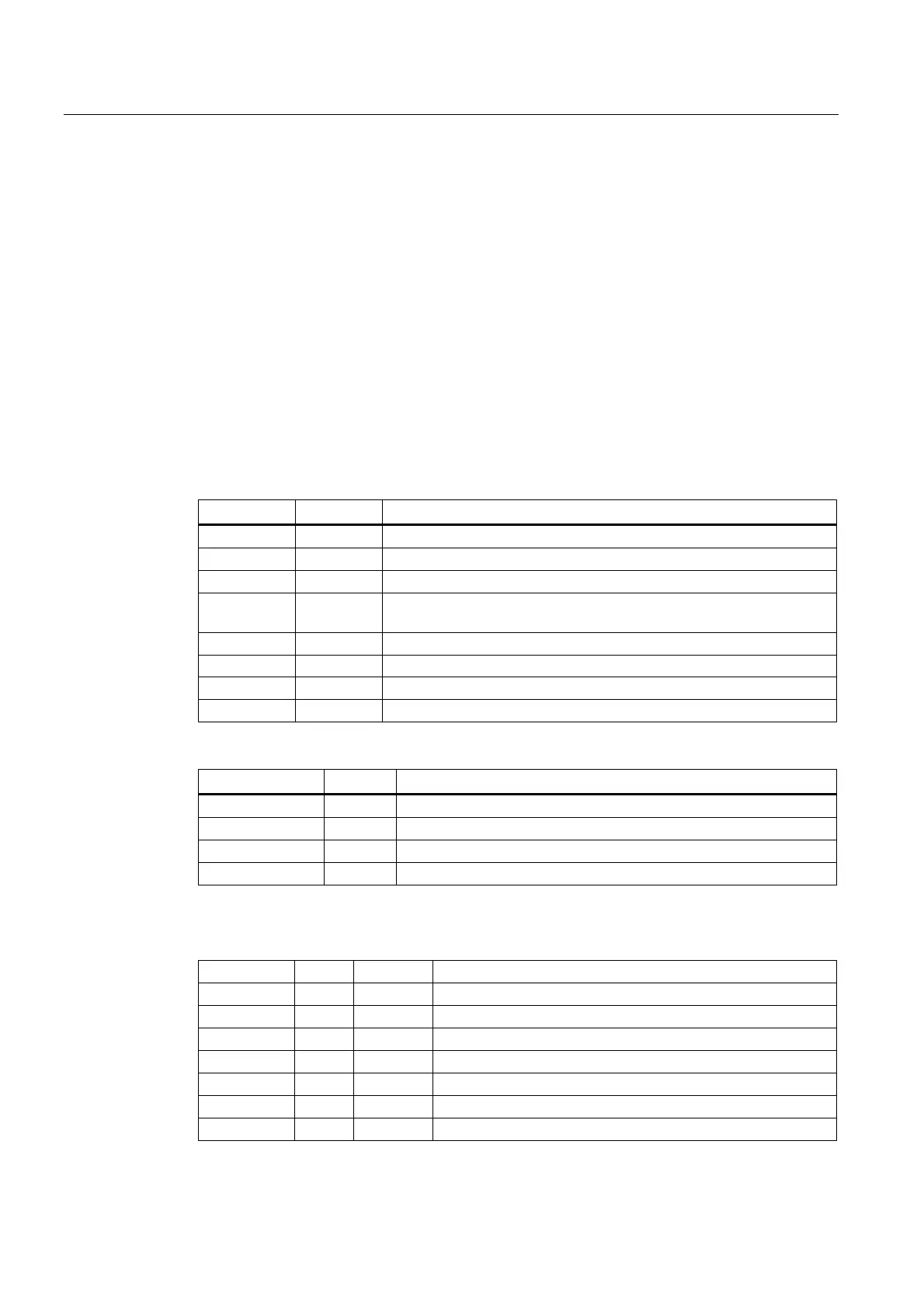

Local variable definition

Table 3- 21 Inputs

Name Type Description

D_CHG WORD Gear change delay time (unit: 0.01 s)

D_MON WORD Gear change monitoring time (unit: 0.01 s)

D_S0 WORD Spindle stop delay time (unit: 0.01 s)

T_GC WORD Monitor time for whole gear change process, must > D_CHG + D_MON

+ D_S0 (unit: 0.01 s)

S_hold BOOL Signal of zero spindle velocity (NO)

S_alarm BOOL Spindle alarm (NO)

LGi BOOL Low detection switch (NO)

HGi BOOL High detection switch (NO)

Table 3- 22 Outputs

Name Type Description

LGo BOOL Low gear output

HGo BOOL High gear output

LG_LED BOOL Status display for the low gear

HG_LED BOOL Status display for the high gear

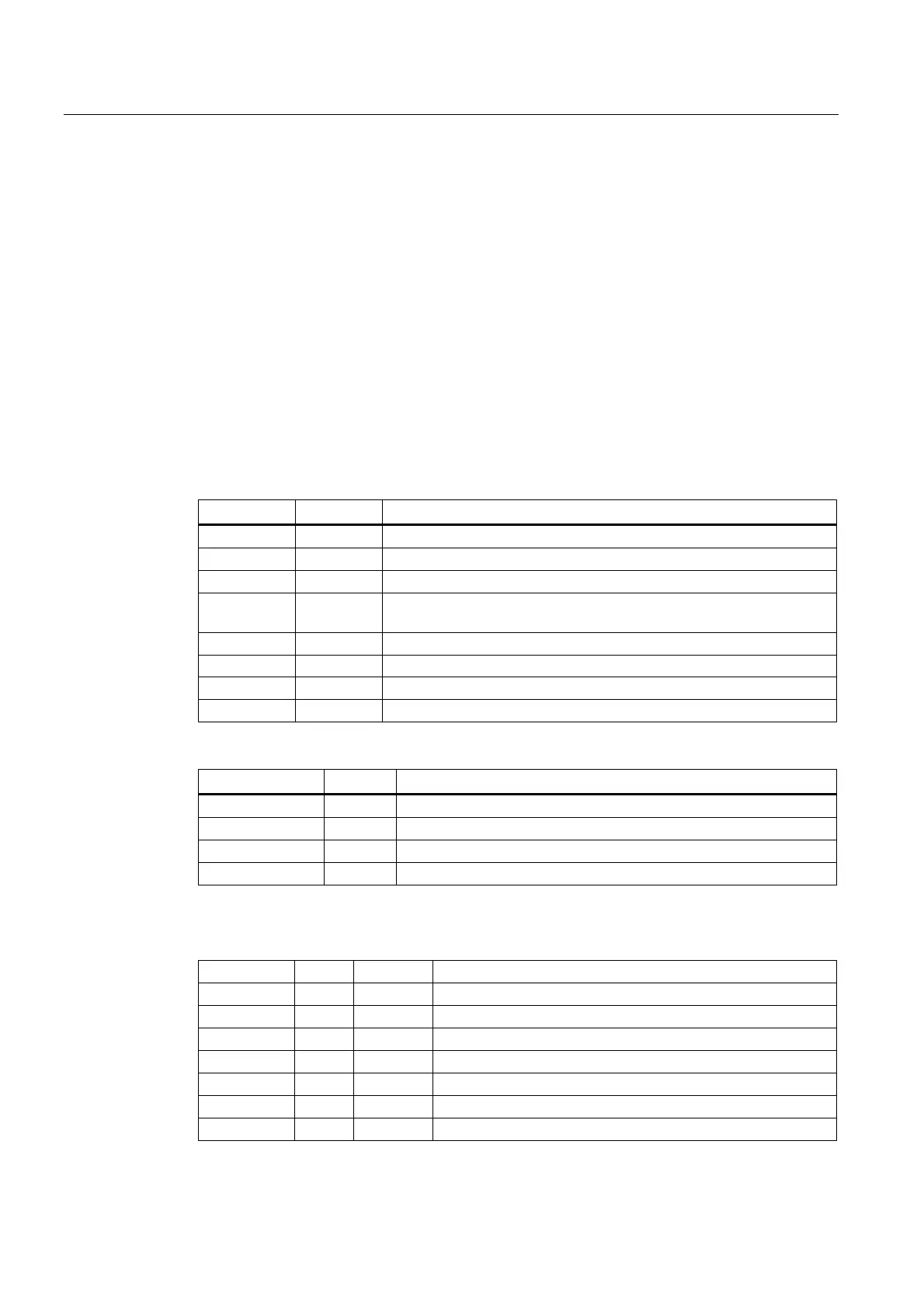

Assigned global variables

HGom BOOL M248.0 Signal indication of high gear stage output

LGom BOOL M248.1 Signal indication of low gear stage output

HGcmd BOOL M248.2 High gear level command

LGcmd BOOL M248.3 Low gear level command

SPhold BOOL M248.4 Spindle stops and ready for oscillation

Dstill BOOL M248.5 Signal for spindle stop

Dchg BOOL M248.6 Spindle gear change delay

Dmon BOOL M248.7 Monitoring for the gear change

Loading...

Loading...